Blog

Ingredient Batching for Rubber

Ingredient batching for rubber compounding requires process knowledge and an expert level understanding of material weighing and batching system control/automation.

Dust Containment for Ingredient Batching Systems

Sterling Systems & Controls, Inc. custom engineers ingredient batching systems for dusty, difficult to handle materials, sometimes hazardous materials. Dust containment for ingredient batching systems is essential to protect personnel and equipment.

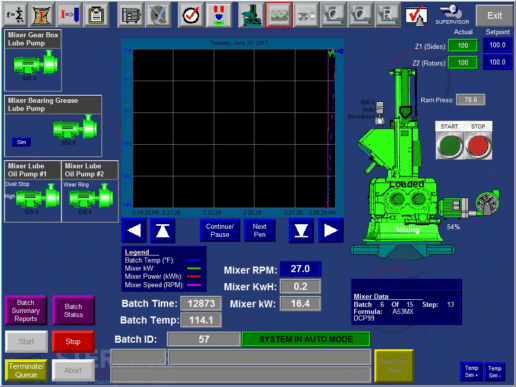

Mixing Control for Compounding

Mixing control is critical to quality and production efficiency. Producing rubber combines plastic resin (pellets, flakes, powders, or liquid) is with other materials, including liquids and bulk solid materials. Sterling Systems & Controls, Inc. offers a mixing control system for rubber compounding. An HMI mixing screen is provided as an extension of the main batching screen.

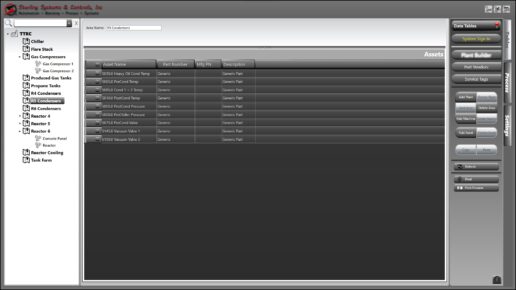

How Preventative Maintenance Leads to Predictive Maintenance

Preventative maintenance is a crucial aspect of asset management in various industries, ranging from feed mills and food processing facilities to rubber compounding and many others. It involves the proactive upkeep of equipment and machinery to prevent unexpected breakdowns, minimize downtime, and optimize operational efficiency. Preventative maintenance software, often integrated with artificial intelligence (AI) capabilities, plays a pivotal role in streamlining these maintenance processes.

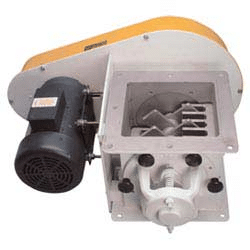

Lump Breakers

No… not the lump in your throat. Lumps that occur in powder and other bulk solid materials that are a nuisance to material processing and powder flow. Lump breakers (a.k.a. powder crushers, lump crushers) are mechanical devices that break down larger bulk solid materials into smaller pieces for proper and easier processing and handling.

Food Safety News

Food Safety news occurs frequently. “New Food” magazine recently wrote an in depth article on Food Safety with quotes from Papa John’s, Chipolte and other companies. Sterling Systems & Controls, Inc. food safety efforts in the ingredient weighing and batching area include lot tracking for ingredients and batch validation.

Pulse Milling

After reviewing a recent blog about Pulse Milling by Prater Industries I thought it worthwhile to share and post here at our Sterling Systems & Controls blog

Sand Facility Control System

The basic configuration for a sand facility control system includes a customized Rockwell Automation Factory Talk machine Edition (ME) software running on a desktop PC, interfaced with the PLC Control Panel, a Motor Starter Control Panel and Sterling Systems unique SandTrack™ software with WebCentral™ remote supervisory control software application. This is typically a system used for sand drying and loading/distribution.

System Supplier Make a Difference?

Does your system supplier make a difference? When you need a custom-engineered solution to meet your objectives for ingredient batching, material weighing, process control, process automation, bulk bag filling or unloading etc., the choices you make based on what the available suppliers bring to the project for you …. can make all the difference in the world. It’s easy to preach sales platitudes, but promising and delivering is a different story.