Liquid Colorant Dosing

An application completed by Sterling Systems & Controls, Inc. required the injection of one of several colorants (sometimes referred to as pigments) into one of two mixers that combine a dry solid material, liquid resins, and colorants. Sterling Systems & Controls can design and provide liquid colorant dosing systems as standalone elements or as part of an overall system.

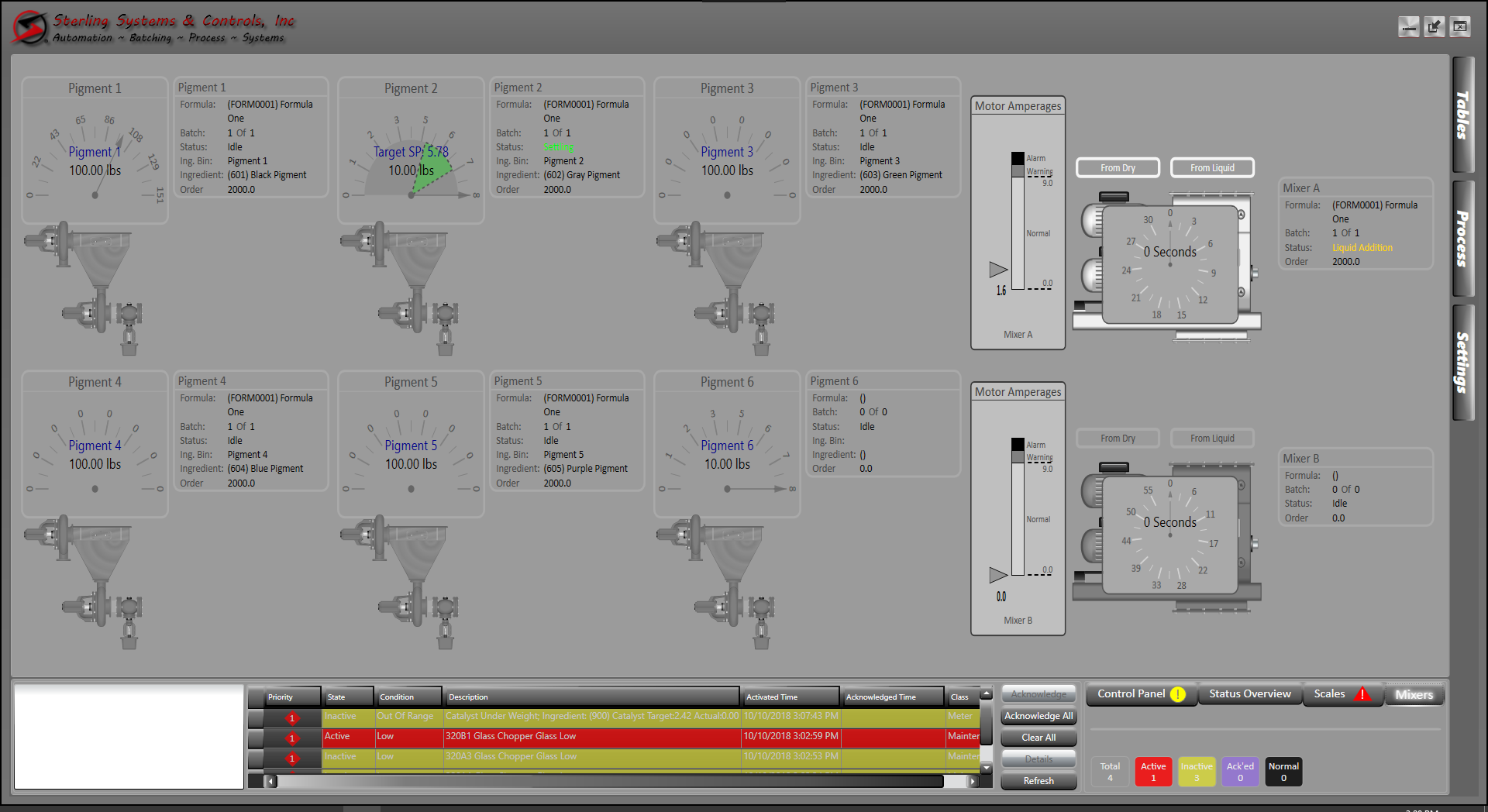

In this example, each liquid colorant dosing station (supplied by Sterling Systems & Controls) is a skidded package with a supply pump, bulk supply barrel, dosing hopper, injection pump, dosing meter, and piping.

The overall system included a dry material and liquid batching system direct to one of two mixers. Colorants were dosed directly into the mixers. One mixer was dedicated for use as a “single color only” mixer; the second mixer could be dosed with one of five colorants, depending on demand requirements.

Sterling Systems & Controls also provided the overall process controls and automation system. The control system included a VFD electrical control panel and an automation control panel. The system PLC was an Allen-Bradley unit and the operator interface was a touchscreen PC running a Sterling Systems & Controls customized Microsoft.NET software system. The automation system displayed and controlled the entire batching and mixing control system, including the addition of the colorants.

Five (5) colorants were dosed to one mixer and one (1) was dosed to the other mixer. Liquid colorant dosing is another capability of Sterling Systems & Controls. Dry material, liquid batching, mixer control. Sterling Systems & Controls is capable of delivering high-efficiency systems that increase your profitability.