Supervisory Control

WebCentral™ is a browser-based supervisory control software package. WebCentral allows users on a corporate network to access data from a Sterling Systems & Controls, Inc. control system, such as a batching control system. WebCentral provides the ability to manage many aspects of the process control system. These can include Ingredients, Formulas, Bin Assignments, Schedules, and other data tables. It also allows for the viewing and printing of historical batching and process data reports. PLC-based control systems are generally constrained by limited PLC memory. They can only hold a limited amount of data (Ingredients, Formulas, etc) at one time. WebCentral stores data in a Microsoft SQL Server/Express database. Therefore, nearly an unlimited amount of data can be stored and maintained. WebCentral monitors key processes, batching data, and alarm conditions within the control system. It provides logging and historical analysis of this data.

In short, PLC’s and Control Systems are good at controlling equipment. Computers and Databases are good at managing data. WebCentral supervisory control provides the means to bridge these two worlds to provide a seamlessly integrated solution.

Technical Overview

WebCentral™ uses browser-based technology to provide supervisory control. This provides easy access to data from any computer that is on the same network as the computer hosting WebCentral. WebCentral does not require internet access as all network traffic and data reside internally on the plant network. WebCentral does require a server to host the application which can be reached by any corporate PC user who needs the data. The hosting server/computer must also be able to reach the PLC/Control System network. This usually means that the hosting server/computer will require two network cards. One network card for accessing the corporate network, and one network card for accessing the isolated control network. WebCentral supervisory control applications can be accessed via smartphones or tablets, provided those devices can join the corporate network. WebCentral cannot be reached natively from outside of the plant via the internet. If a corporate VPN is in place, and applicable corporate policies, WebCentral can be used remotely from the plant network. This takes place once a VPN connection to the plant network has been established.

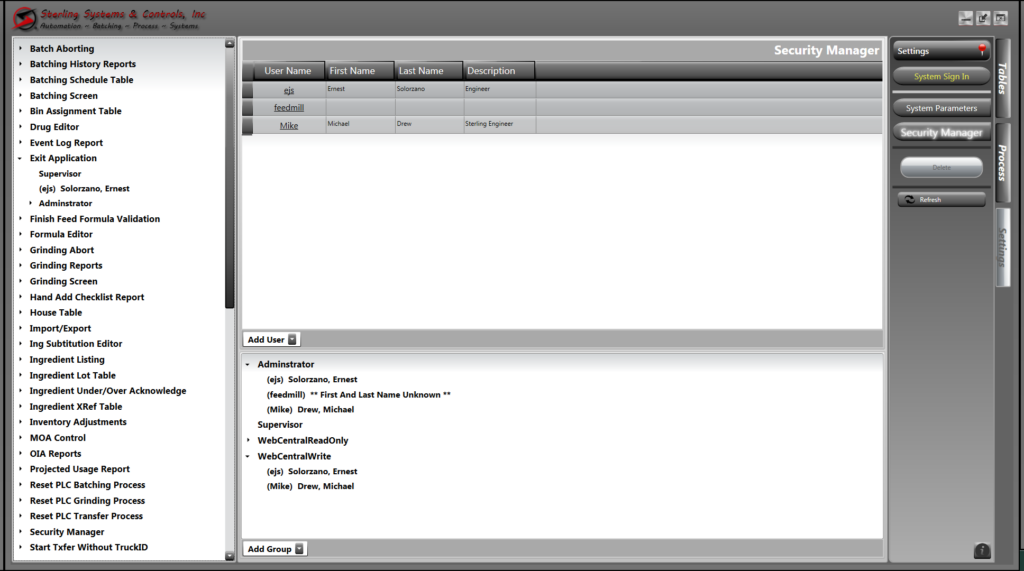

WebCentral™ Security

Access to the features of WebCentral™ is controlled via a flexible security system. The security system is configured by using the Security Manager screen in the process control system software. Individual users of the control system can be created and then can be assigned to groups. Permissions can then be assigned to a group or directly to a specific user. As users come and go, they can easily be added or removed from the appropriate group. Individual permissions won’t need to be modified. Users and groups can be assigned Read and/or Write permission to each screen in WebCentral individually. It is easy to configure just the right amount of access for each job function.

General Navigation and Data Editing

Click the link on the menu bar for the WebCentral™ screen you want to view. If the button for the screen you want to work with is not visible, then you do not have Read access. If you have been granted Write access to a screen, you will see several icons in the first column of each row in the table. Hovering your mouse pointer over these icons will display a hint of what the icon does.

Most screens are separated into multiple pages. You can navigate between the pages by clicking on the number of links at the bottom of the grid. Many screens provide the ability to re-sort the records by simply clicking on the heading in the grid. You may also search and filter information in the grid using the search fields located at the top of most of the grid screens. Next, we look at a couple of example screens to illustrate how easy it is to view and change data from the supervisory control provided by WebCentral™.

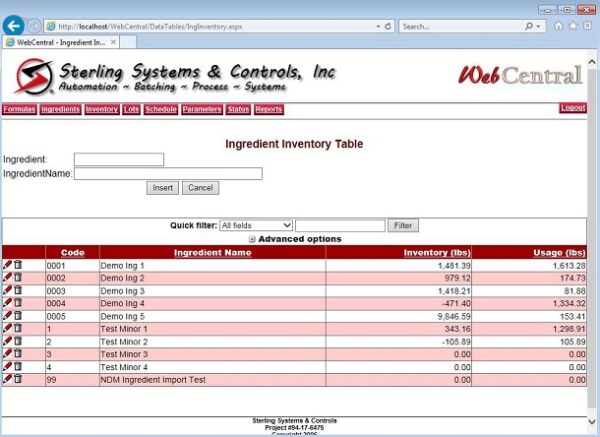

Batching System Example – Ingredient Screen

The Ingredient screen contains a listing of all ingredients the control system will use in any formula. Clicking the pencil “Edit” icon will allow the current row to be edited. Clicking the garbage can “Delete” icon will delete the selected record. New ingredients can be inserted using the form at the top of the page. Ingredient records can be expanded to view more detailed information using the plus icon. For information about the fields and how they are used by the control system, refer to the Batching System Operations Manual.

Other WebCentral™Screens

Many other screens are available in WebCentral™. For a batching control system, this may include:

- Formula Screen

- Formula Editor Screen

- Bin Assignment Screen

- Ingredient Lot Table Screen

- Batching Schedule Screen

- Loadout Orders Screen

- Transfer Times Screen

- Transfer Queue Screen

- Batching System Parameters Screen

- Batching Status Screen

WebCentral™ Reports

WebCentral™ contains many different reports that can be run to extract and display the information. Clicking on the report links will prompt the operator for additional information such as dates and times, if required. Then the report will be displayed on the screen. Reports can be exported to a PDF, Excel, or Word document by clicking the disk “Export” button and selecting the desired format.

Conclusion

The Sterling Systems & Controls, Inc. WebCentral™ software application is an important part of your overall plant control system. It is a supervisory control application. It allows an unlimited number of personnel to remotely view and change data in your Sterling Systems & Controls system. This can be done from their remote office or location. They are required to be connected to the same network as the Control System software. PLC’s and Control Systems are good at controlling equipment, whereas Computers and Databases are good at managing data. WebCentral provides the means to bridge these two worlds to provide a seamlessly integrated solution.