Mineral Processing Control

Many materials are valuable and require automated control. Mineral processing control is especially important for high-value minerals, such as calcium carbonate. Especially calcium carbonate, which is of a highly pure nature. In this application example, a customer needs to automate the control of their mineral milling process efficiently. The process control system needed to be custom-engineered to meet the customer’s very specific objectives for their mineral processing business. How large of a processing operation? We can’t reveal too much but just suffice to say the P&ID is at least a dozen sheets with hundreds of measuring and process control points. Needless to say, mineral processing control can require extensive equipment and automation.

Sterling Systems & Controls, Inc. worked with the customers and listened to them as they described their objectives over several discussions. Sterling Systems & Controls dedicated engineering personnel (no contract engineers) worked as a team with a project manager leading and involved from the point of sale through startup, and they continue involvement running point working with the customer to make modifications and updates so that the process automation and control system works to optimize the process, finished product, efficiency and profitability. The Sterling Systems & Controls automation system included:

- One (1) PLC Main Control Panel

- Three (3) Operator Stations

- Twelve (12) UL Listed Ethernet I/O PLC Control Panels

- Six (6) MCC back panels with PLCs

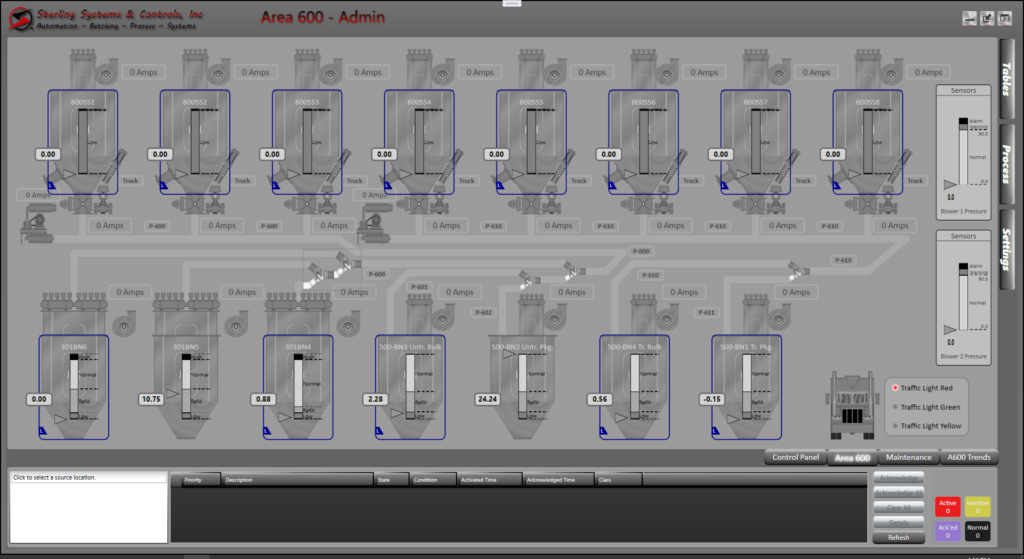

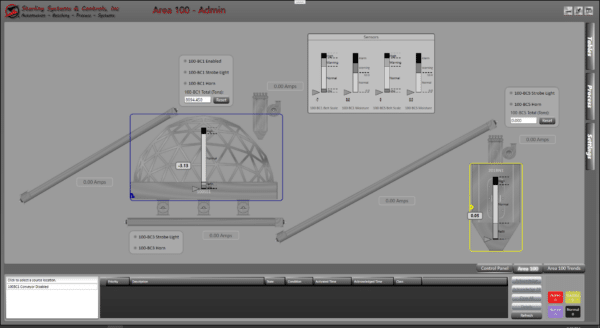

- Sterling Systems & Controls state-of-the-art .NET application software including Process Screens, Recipe/Formula Screens and Real-Time Trending and Troubleshooting Screens.

- Sterling Systems & Controls PMPLanR Preventative Maintenance Planning Software Application.

The three (3) HMI operator control stations located on the production floor in the packaging and loadout areas are supplied in NEMA4/12 mild steel, wall-mounted enclosures, with NEMA4/12 vortex coolers. Inside each panel is a thin client connected to a virtual machine in the

control room. Each HMI Touchscreen Panel displays Sterling Systems .NET software and is located on the processing floor near each area of its control (edge control location).

From the HMI PC workstations, the operator can define operating parameters including alarm setpoints, ingredients, ingredient parameters, formula/setpoints with required ingredients and their weights. The software can have multiple security levels.

To receive operating parameters the virtual machines communicate via the Ethernet HMI network to a PLC that is mounted in the control room.

The PLC interfaces with the Ethernet IO, MCC PLC racks/modules, as well as the VFD’s on the PLC network. There are two dedicated networks, one for HMI communication and the other for PLC/VFD communication. They interface with MCC buckets and the 120-volt 60 Hz and 4-20 ma signals to the batching and process control equipment.

As part of Sterling Systems & Control’s standard support strategy, the PLC and HMI programs are easily modified via VPN access, eliminating costly service calls. All of the components and software used are non-proprietary and are available from hundreds of suppliers.

All HMI screens conform to ISA101, ISO11064-5, and ASM standards and guidelines. All communication protocols between thin clients and host machines will be RDP.