Multiple Batching Stations

Batching Control Systems with Multiple Batching Stations

In this application example, Sterling Systems & Controls, Inc. implemented a batching control system with multiple batching stations. Often there is only a single batching station. This application was provided with three batching stations using a single Allen-Bradley PLC controller. The customer has two areas or lines, each requiring a locally accessible batching station.

The first line has only one batching station, but adding a second batching station is expandable if required. The second line has two batching stations which, in this food processing and baking application, share flour, oil, and water as their bulk ingredients. Multiple batching stations are provided for the total system to deliver operator convenience and overall system flexibility. Typically when each batching station calls for flour or oil, the PLC request will be handled as first come first serve (FIFO). Flour is conveyed pneumatically and oil is pumped to either mixer as available. Water, however, can be tempered or chilled. Water going to each mixer can be called at any time without waiting for the other to finish because each mixer has a dedicated flowmeter for each type of water that is monitored to meter how much water goes into the mixer.

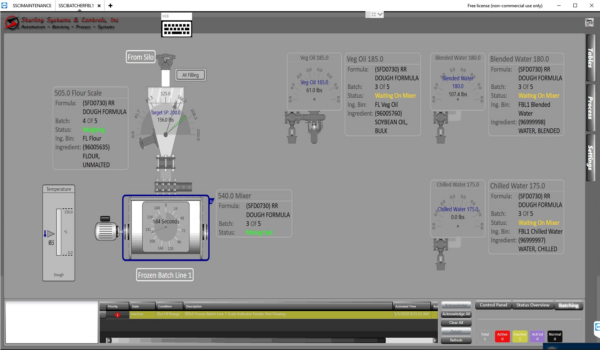

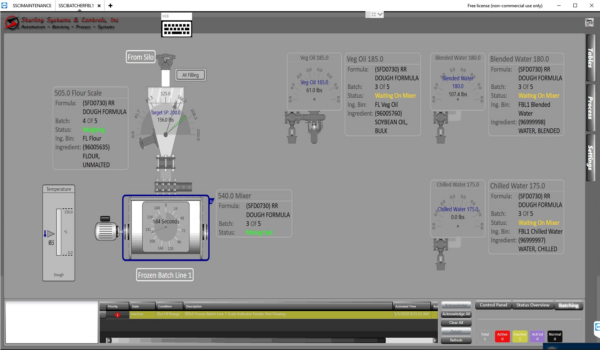

Batching Screen

The Batching screen shows a flour scale mixer and liquid meters. When the equipment or vessel is on or active, the graphic will go from dark gray to bright white. If an alarm exists on any equipment, a red square surrounds the device with a pulsating red triangle. Each batching vessel has a batch block, including ingredient and bin information. The text that shows the status is color-coded, indicating any abnormal condition as red, normal operation as green, waiting condition as orange, or idle condition as black. Each ingredient bin above each scale shows the calculated level as a narrow bargraph, and they are color-coded as well. The color coding is determined by the level setpoints and bin inventory in the bin assignment table . The bargraph will be blue if above the warning setpoint, yellow if between the warning and low setpoint, and red if below the low setpoint. Each scale has a scale gauge that shows the target setpoint and net amount underneath. A green band on the gauge is the graphical representation of the target weight setpoint. The needle will move closer to the green band as the scale hopper fills. The modern touchscreen graphic display conforms to ISO 11064, ISA101, ANSI, and ASM standards and practices.

The second part to the batching system is the mixer controls. The batching stations do not directly control the mixer operation but the mixer speed references and flour slide gate open/close commands are sent to a separate mixer controller. The mixer controllers and their programming were supplied by a different vendor in this case. This other vendor has Allen-Bradley PLC mixer controllers at each of the multiple batching stations and the batching stations communicate with the mixer controllers over the Ethernet/IP network. They also send the Sterling Systems & Controls batching system status and alarm conditions that are displayed and notified on the batching system HMI. Once each batch cycle is finished, the mixer operation takes control to tilt the bowl down and “kick” the dough out into a trough. Pizza crust and flatbread are the end product made at the customer plant.

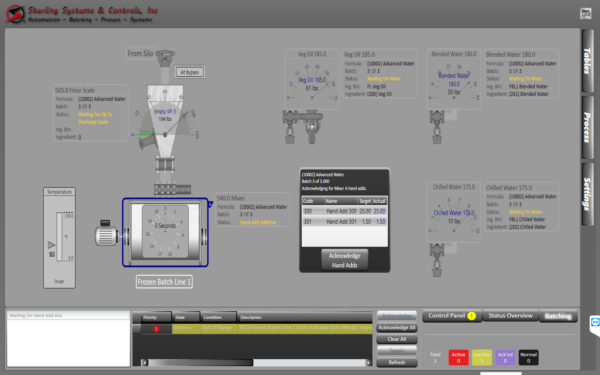

Batching Screen with Hand Prompts

Hand-adds were also a part of the overall batching system. Hand-adds and premix’s are prompted and can be acknowledged from the batching stations. One unique aspect of this specific batching system application, compared to others Sterling Systems & Controls has completed, is that the commissioning of both of the two lines was done remotely, due to restrictions imposed by the customer and Sterling Systems & Controls to protect all employees. Sterling Systems & Controls, two electricians, the customer, other contractors, and customer IT people worked together remotely regarding installation questions, IO checkout involvement, equipment configurations and setup, and training.