Bag Dump Station

The Bag Dump Station is typically used to empty small bags of bulk solid material, such as various powders, into a bulk material handling and processing system. The bulk bag dump station is used in various industries and applications. The basic unit usually consists of a hopper, hinged lid, outlet cone, bag support shelf, and grate. The Sterling Systems & Controls bag dump station is custom-engineered to meet the exact requirements of our customer’s process, often including dust collection to control the spread of dust during the dumping process. Bags are lifted and set on the grate where they are then opened and the material emptied into the hopper. The grate helps keep the bag or parts from falling into the hopper. Dust collection is such that a downward airflow is pulled below the grate, removing the dust away from the operator. Materials of construction can be mild or stainless steel.

A common use and application combines Sterling Systems & Controls semi-automatic hand-prompt batching stations with bag dumps to introduce the collected batch into a conveying system for transport downstream for further processing. A pneumatic conveying system moves the collected batches downstream. A blower system beneath the hopper creates the pneumatic pressure to convey the material.

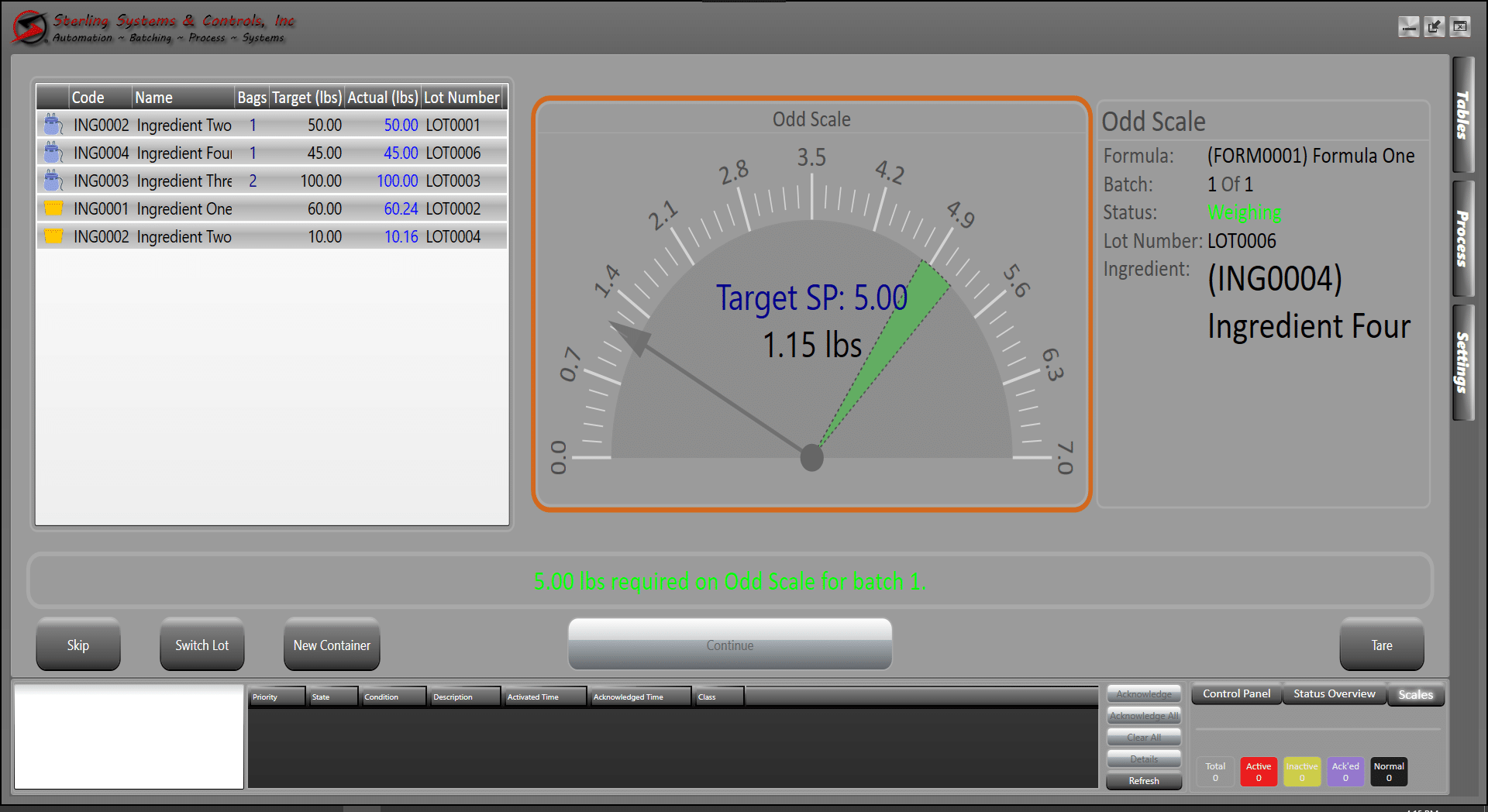

The Sterling Systems & Controls semi-automatic batching station ensures that the batches are manufactured to the formula criteria while validating and documenting the process with excellent reporting capabilities. The results are the production of consistent, quality products with increased production and batch accountability (i.e., amount weighed, batch number, ingredient lot numbers, start/finish times, operator management, time/date stamp, etc.).

The Hand Prompt Batching Station control panel incorporates an embedded industrial PC and a large touchscreen display for the operator interface. The combination provides a rugged and cost-effective platform for a demanding factory environment. The system provides a single lighted pushbutton, protecting the touchscreen element from excessive wear and tear. The enclosure is water resistant to protect it during cleaning.

Bag Dump Station Semi-Auto Batching System

The Semi-Automatic Hand Prompt Batching Station is highly configurable and can be adapted to virtually any process method, unlike the manual batching stations available from others. The Hand Prompt Batching Station control system prompts the operator, via the touchscreen, through the chosen formula with one ingredient at a time, ensuring that the correct material is being used. The required ingredient is displayed for the operator; the operator enters the ingredient details or scans the product, and if the correct ingredient is entered, the system will display the required weight. Once the weight is within a programmable tolerance, the system will ask the operator to acknowledge that this ingredient addition is finished, then it is acceptable to move on to the next ingredient. Once the operator acknowledges, the Hand Prompt Batching Station system will continue to the next ingredient, once again if it is within tolerance the system will prompt the operator to continue to the next ingredient until the batch is complete.

After a batch is complete, the Hand Prompt Batching Station system can print a batch summary with individual ingredient information, including the ingredient number, name, required weight, actual weight, and lot information. The system software will also allow the scheduler to assign a lot number to each batch so that the batches may be searched by the lot number. A “move ticket” can be printed and attached to the container for identification and tracking in further batch processing.