Mixing Control for Compounding

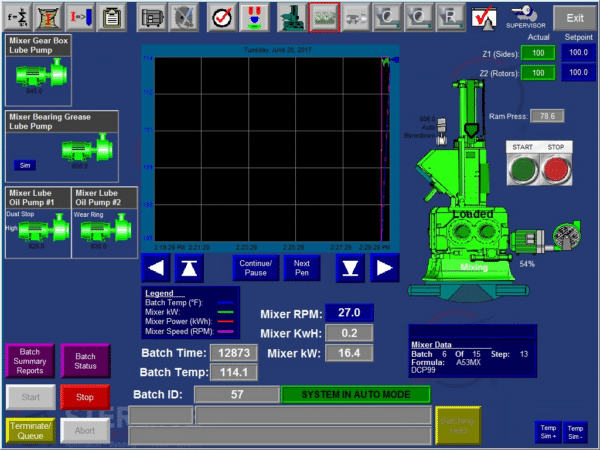

Mixing control is critical to quality and production efficiency. Producing rubber combines plastic resin (pellets, flakes, powders, or liquid) with other materials, including liquids and bulk solid materials. Sterling Systems & Controls, Inc. offers a mixing control system for rubber compounding. An HMI mixing screen is provided as an extension of the main batching screen. This shows all of the equipment associated with the mixer. The user has the capability to control the mixer’s RPM on the formula being run, along with the capability to view the status of and control related equipment. This mixer control system offers a data trending screen that allows viewing the batch temperature, mixer torque, mixer power, and mixer speed for the last twenty hours.

The controlling software for a rubber batching system is typically a Sterling Systems customized software system running on either a PC or a HMI. In the HMI case it is usually a Sterling Systems custom Rockwell Software FactoryTalk View ME running on PanelView Plus Touchscreen HMIs located in the operator control panels where formulas and ingredients are created and scheduled to batch.