Case Studies

Baking Industry: Upgraded Batching Solution

Unlock the secrets behind a 25-year partnership’s success! Dive into Sterling Systems & Controls’ latest case study featuring a middle-America bread producer. Seeking to modernize their operations, the producer turned to Sterling for upgrades to their batching and material handling systems, aiming to reduce manual labor and boost production.

Rubber Industry: Minor Ingredient Batching System

Sterling Systems & Controls was approached by a hose manufacturer grappling with inefficiencies in their manual batching and weighing of powder ingredients crucial for their rubber products. Seeking a tailored solution to enhance production processes, they turned to Sterling, known for its expertise in custom engineering and manufacturing of weighing systems and automation.

Micro/Minor Weighing System With Bulk Bags

Explore this case study, highlighting Sterling’s innovative solution for a leading animal feed producer. In response to the client’s pressing need for enhanced batch efficiency, precision, and labor optimization, Sterling delivered a tailored Micro/Minor Weighing System with Bulk Bag capabilities.

Control Automation Conveying and Grading System

Embark on a journey into the dynamic realm of industrial automation through Sterling Systems and Controls’ latest case study. Tasked with orchestrating an automation control system for a sugar grinding and conveying system, Sterling confronted a distinctive challenge: crafting controls for a conveying/sifting system capable of unloading bulk bags of coarse granulated sugar at precise rates and sorting the product into three mesh sizes for future processing needs. Delve into the narrative to witness how Sterling approached this challenge head-on with their ingenious solutions.

Minor Ingredient Weighing & Batching System

Discover how Sterling Systems and Controls revolutionized a bakery’s production process with their innovative Minor Material Weighing System and Batching Controls. By ensuring precise weighments of minor ingredients for bread dough, Sterling’s solution facilitated consistent batches of Buns, Bagels, French Bread, and Italian Bread Products every time. But the challenge was substantial: storing and weighing ten raw ingredients with maximum accuracy throughout a full day’s production, all while meeting space restrictions and eliminating the risk of missing or double-dosed ingredients.

Feed Industry: Batching Solutions

Discover how Agri-King, Inc., a leading animal nutrition company, partnered with Sterling Systems and Controls to overcome their automation challenges and enhance their operations. Initially adopting Sterling Systems in the 1970s, Agri-King faced the dilemma of aging hardware and obsolete components by 2013. Sterling’s Sales and Engineering teams meticulously assessed the situation, proposing a comprehensive upgrade tailored to Agri-King’s needs.

Food Industry: Weighing & Batching Solutions

Explore the fascinating journey of an iconic American breakfast food company spanning over a century of innovation and dedication to providing families with delicious and nourishing morning meals. With a rich legacy of crafting over twenty beloved breakfast products distributed globally, this company has remained steadfast in its mission to transform grains into wholesome foods for generations. However, faced with the challenge of adapting to dynamic raw material availability and escalating competition, the company sought to revolutionize its production process for waffles.

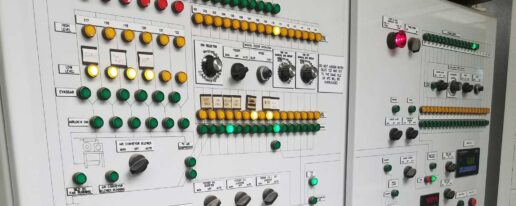

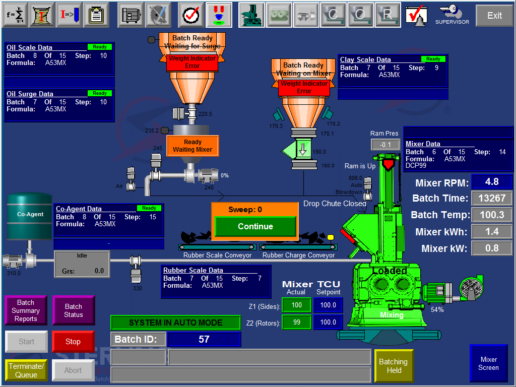

Rubber Industry: Batching & Mixing Controls Solutions

Witness the transformation of rubber compounding batch integrity and production efficiency as a global leader in hydraulic hose manufacturing joins forces with Sterling Systems & Controls. Striving to overcome limitations imposed by an outdated batching system, the company sought to automate the handling of bulk materials and streamline processes in their Banbury® mixer. Sterling Systems & Controls rose to the challenge, crafting a tailored solution to not only address existing inefficiencies but also pave the way for future growth and competitiveness.

Recent Posts

Weighing and Batching Solutions for The Food Industry

Beginning with their first successful breakfast cereal, this American company has been producing delicious and nutritious ready-to-eat breakfast products for over 100 years. The company now produces over 20 well-branded breakfast foods and distributes them to hundreds of countries worldwide. Over their long history the company has seen many changes but their goal is still to transform grains and other materials into good for your family foods.

Feed Mill Automation Migration & Upgrade

Sterling Systems & Controls, Inc. announces that it provides for migration and upgrade of automation within their batching control. This is important for long term operation of the feed mill within the feed manufacturing industry. A major livestock feed manufacturer has seamlessly maintained state-of-the-art feed mill automation and control of the feed manufacturing processes across several decades.

Bulk Bag Unloading and Weighing System

Sterling Systems & Controls, Inc. is pleased to announce the availability of its line of bulk bag unloading systems. These customized unloading systems can include bulk bag discharging, material weighing and batch dispensing, along with the controls required for automatic operation. Just such a system has been successfully operating at the site of a leading manufacturer of sugar free and no sugar added baked desserts. The comprehensive bulk bag unloading system for premixed food ingredients incorporates the mechanical structure which houses and supports the bag discharge, material weighing, dispensing (flexible screw conveyor) and control panel components.