Rubber Industry: Batching & Mixing Controls Solutions

Witness the transformation of rubber compounding batch integrity and production efficiency as a global leader in hydraulic hose manufacturing joins forces with Sterling Systems & Controls. Striving to overcome limitations imposed by an outdated batching system, the company sought to automate the handling of bulk materials and streamline processes in their Banbury® mixer. Sterling Systems & Controls rose to the challenge, crafting a tailored solution to not only address existing inefficiencies but also pave the way for future growth and competitiveness.

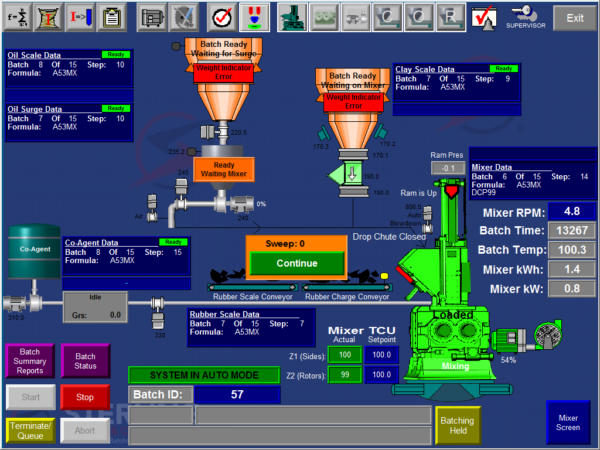

Sterling Systems & Controls orchestrated a comprehensive control system, meticulously integrating four key processes: Hand Add Weighing, Main Batching, Mixing, and Batch-Off. This intricate system featured Manual Add Stations with intuitive control panels and HMIs, empowering operators to batch ahead and optimize production workflows. Through RFID scanners and scale integration, precise ingredient weighing was ensured, while a user-friendly graphical schedule display facilitated seamless batch scheduling and monitoring.

Harnessing Sterling Systems & Controls’ expertise in automation and process control, the client witnessed a remarkable enhancement in batch integrity and production efficiency. The innovative solution not only addressed immediate challenges but also equipped the company with robust records for precise inventory management and quality control. Dive into the full case study now to explore how Sterling Systems & Controls revolutionized rubber compounding, offering insights into the transformative power of customized automation solutions for your organization’s journey towards efficiency and competitiveness.

Download now to embark on your automation journey.