Press Releases

Improving Manual Batching

Our line of semi-automatic Hand Prompt Batching Stations can be custom engineered with options to meet the specific requirements of applications, thereby improving manual batching, which can improve your entire process of product production. The Semi-Automatic Hand Prompt Batching Station serves a wide range of industrial applications where the negative effects of time-consuming and problematic manual batching need to be eliminated.

Filling and Packing Stations for Bulk Bags

Sterling Systems & Controls, Inc. is pleased to announce the availability of its new line of Filling and Packing Stations for Bulk Bags (FIBCs). These Bulk Bag Filling Stations fit a wide range of bag sizes and can be provided to fill and weigh capacities of 100 lbs—4400 lbs.

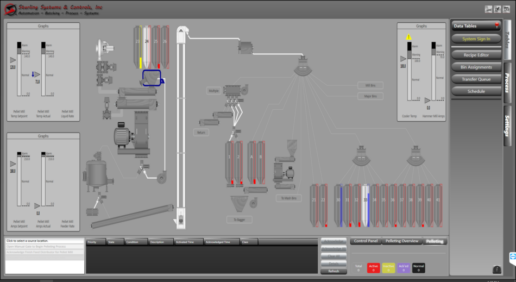

Pellet Mill Control and Feed Mill Automation

Sterling Systems & Controls, Inc. is pleased to announce the availability of its state-of-the-art process control and automation of pelleting mills and processes that may be found in feed mill and pet food manufacturing facilities. Pellet Mill Control and Feed Mill Automation: This new automation software is designed using Windows based .NET framework technology for greater openness, graphics and overall capability to simplify operation and improve efficiency of cost and throughput.

Bulk Bag Unloading Systems Customized

Sterling Systems & Controls, Inc. is pleased to announce its line of custom engineered bulk bag unloading and material weighing systems. These bulk Bulk Bag Unloader with Magnetbag unloading systems are designed to meet customer objectives and can include custom frame engineering to fit your specific facility requirements.

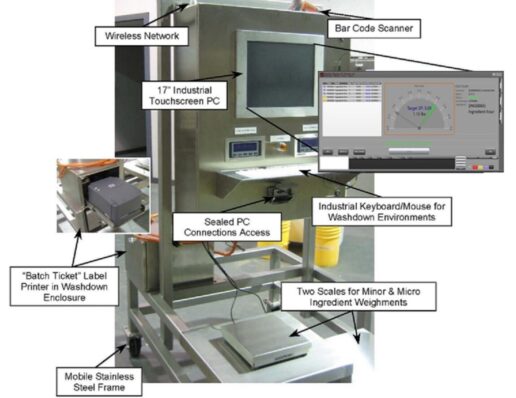

Semi Automatic Batching Station

Sterling Systems & Controls, Inc. is pleased to announce the availability of its affordable Semi-Automatic Batching Station that can eliminate bad batches typically associated with manual batching, and assist in meeting product safety goals with lot tracking and batch validation capabilities. This Semi-Automatic Batching Station serves a wide range of industrial applications where the negative effects of time-consuming and problematic manual batching currently need to be improved.

Bulk Bag Unloading Systems

Need to unload bulk bags, a.k.a. FIBC bags? Often this requires customization of the unloading system. e.g. surge hopper, dust collection, magnet, airlock, weighing system, etc? Bulk bag unloading systems come in many “colors” and finding the supply partner that can custom engineer bulk bag unloading systems to meet your specific objectives is very key to your success.

Auger Feeders Ensure Batching Reliability

Sterling Systems & Controls auger-type screw feeders are a critical component within ingredient batching systems for food processing, feed milling and many other industrial applications. Auger feeders ensure batching reliability from Sterling Systems excelling beyond other brands with three key features...

Mechanical Conveying Automatically Discharges Batches

Sterling Systems & Controls, Inc. is pleased to announce the use of a Mechanical Conveying system to automatically discharge and move batched ingredients through to the blending and mixing process.

Mill Monitoring

For Immediate Release, Sterling, IL: Sterling Systems & Controls, Inc. is pleased to Bearing Condition Monitorannounce the availability of customized mill monitoring systems for use with the Prater brand mills and classifiers. Mills and Classifiers are high speed rotating machinery. Sterling’s Mill Monitors automatically watch over the mill bearing, inboard and outboard bearings, temperatures and acceleration and provide output to control systems.

Hybrid Material Weighing and Batching System

Sterling Systems & Controls, Inc. is pleased to announce in its line of material weighing and batching systems, the availability of customized ingredient hybrid weighing and batching systems with Micro, Minor and Bulk weighments, processing both dry and liquid ingredients. Each automatic Accu-Portion™ Micro and Bulk Batching System is custom designed and manufactured to meet the specific needs and requirements of the customer. The Bulk supply can be with Bulk Tank, Tote or FIBC Bulk Bag.