Blog

Multiple Batching Stations

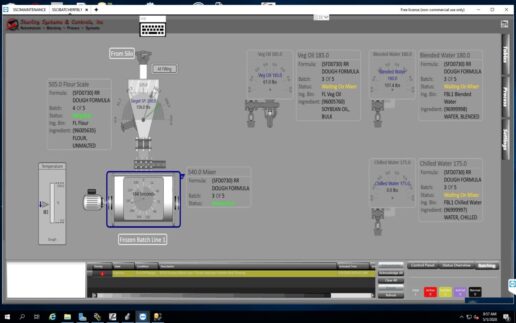

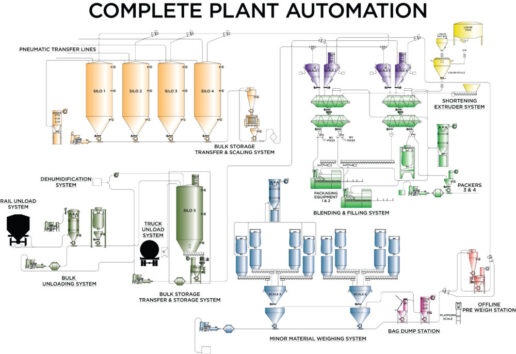

Bakery batching stations can be more simple than other applications or batching system counterparts, such as in feed mills. In this application example Sterling Systems & Controls, Inc. implemented a batching control system with multiple batching stations.

Do Dust Socks Impact Scale Hopper Accuracy?

Yes they “can” impact scale hopper accuracy. But they don’t have to, when the correct dust sock is chosen and installed properly.

Mother Totes for System to Dose Liquids

It isn’t unusual for Sterling Systems & Controls to be called in to fix problems with equipment systems of other brands. One major snack food producer did just that and it involved a liquid dosing system. The solution was mother totes for system to dose liquids.

Automatic or Semi-Automatic Batching

Thinking about automating your purely manual batching? Tired of ruined batches because your operator missed an ingredient or added the wrong weight of a couple of the ingredients? Maybe your operator was interrupted and forgot where they were at in the batching process? All of these things and more can happen and ruin your day because of ruined batches and scrap costs. So what to do? Automatic or Semi-Automatic Batching system. But what is the difference and what should you use?

NEMA and IP Ratings: A Primer

What are NEMA and IP ratings? What’s the difference? Let’s first define each acronym: NEMA stands for National Electrical Manufacturers Association. IP stands for Ingress Protection. In our context we are speaking about the various ratings that can be used to describe the environmental protection provided by enclosures.

How To Fill Bulk Bags

How to fill bulk bags? I understand why many people ask that question. You business is growing, you are thinking about increasing the size of your bagged bulk material for shipment to your customers. No more just offering skids full of 50 or 100lb bags. You need to ship a skid with a 2000lb FIBC on it. Maybe even multiple bulk bag sizes.

Evaluating Your Inquiry

Evaluating your inquiry. Here is how Sterling Systems and Controls does it. Our goal is to customize software, electronics and mechanical equipment to meet your specific goals and specifications, to give you great value and deliver on our promises. Here is what happens evaluating your inquiry:

Handling The Dust Problem

Automatic ingredient batching systems that handle and feed/batch powder materials that are very prone to dusting during feed discharging and supply bin refill can be problematic, requiring an answer for Handling The Dust Problem.

The need for speed …. in batching

The need for speed …. in batching? How do you achieve it, and why? Vibratory Feeders feed critical ingredients into individual scale hoppers. Well there can be a few reasons why you might need your ingredient batching system to operate as fast as possible: 1. Your batching requirements are continuous. 2. Your batching requirements are very large, possibly moving many tons per hour or day.