The need for speed …. in batching

The need for speed …. in batching? How do you achieve it, and why?

Well there can be a few reasons why you might need your ingredient batching system to operate as fast as possible:

1. Your batching requirements are continuous.

2. Your batching requirements are very large, possibly moving many tons per hour or day.

In our last post we highlighted why rollover tub or rotary tub scales are a thing of the past. And multiple scales is certainly impacting batching speed. One example is ingredient batching for cattle feed production applications. In this application there are usually 7, 8 or more ingredients. These ingredients are not just nutrients but also drugs that must be accurately weighed and introduced into the batch. Accuracy is essential to quality feed for maximum safe beef production. The weighments for many of these ingredients are often of the micro size, very small.

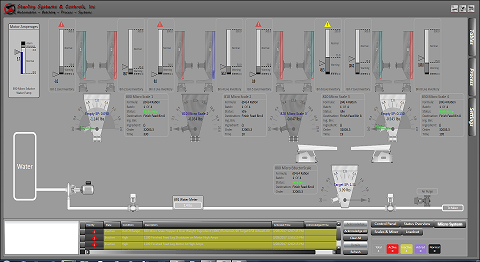

In a cattle feed ingredient batching system it is common to have a scale for each ingredient. In addition, the use of vibratory feeders is also necessary to ensure the highest feed accuracy. The vibratory feeder can be precisely controlled and each ingredient has its own scale and uses high accuracy load cells. In addition, each ingredient storage bin is on load cells. This all makes for a very high accuracy and fast ingredient batching system. Further, the ingredients are mixed with a unique water adding system for transport as well as mixing the dry ingredients.

Some ingredient batching systems will transport mixed batches on virtually and continuous basis using high speed pneumatic or vacuum conveying systems. This can be found in feed and food applications. Usually these fast transport systems will deliver the batched ingredients to a mixer or mixers.

No matter what the need in batching systems is, there is always a custom solution that will work. The trick is knowing how to find it. 815-281-5378 or sci@sterlingcontrols.com

multiple ingredients in breakfast

food manufacturing.