Blog

The Importance of Minor Ingredient Batching Systems in Food Processing

Food processing is an intricate dance where precision meets palate, and consistency defines quality and can dramatically impact brand loyalty. In this competitive industry, minor ingredient batching systems emerge as silent heroes in your production process.

Preventative Maintenance: A Strategy for Ensuring System Reliability

In process manufacturing (food, baking, pet food/treats, animal feed milling, plastic/rubber compounding, and much more), where efficiency and reliability are crucial to product and business success, the choice between maintenance strategies can significantly impact operations.

Cattle Feed Manufacturing in Livestock Management

Cattle feed manufacturing stands as a cornerstone in modern livestock management systems, catering to the escalating demands of a growing global population for meat and dairy products. Its significance extends beyond mere provision; it ensures the health, productivity, and sustainability of the livestock industry.

NEW Particle Size Reduction Guide

A NEW Particle Size Reduction Guide is now available from the leaders in bulk solid Size Reduction of Particles, Prater Industries. A sister company to Sterling Systems & Controls, Prater knows size reduction and Sterling Systems knows how to provide the controls and monitoring equipment to help ensure return on these assets for size reduction.

Key to Process Efficiency

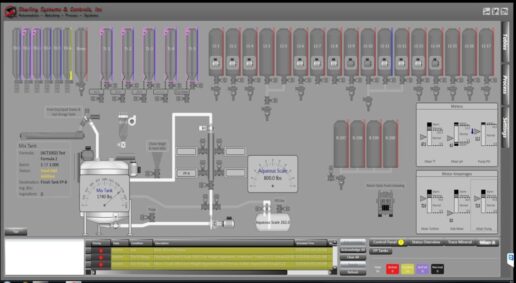

Key to process efficiency is the upgrading of process control and automation technology in your dry material handling, storage and processing. Instrumentation, control and automation technology components and software advancements afford equipment upgrades.

Agriculture Bridges the Gap

The world population has more than doubled in the past 50 years and agriculture bridges the gap. From about 3 billion people in 1970 to nearly 8 billion in 2021. A new opinion editorial in the Feed & Grain website suggests that “with challenges come opportunities for agriculture industries”. I couldn’t agree more, especially here in North America.

Packaging Powder Materials In Bulk Bags

Stations for packaging powder materials in bulk bags typically includes an adjustable upper frame to accommodate either square and rectangular containers, as well as heavy duty weighing, and controls designed to withstand the rigors of tough industrial use.

Dust Containment is Essential

Sterling Systems & Controls, Inc. designs material weighing and ingredient batching systems for dusty, difficult to handle powder and bulk solid, sometimes hazardous, materials. Dust containment is essential to protect personnel and equipment. tom engineered and can be equipped with dust control and containment options, including a dust collector (typically baghouse design), dust collector hoods over ingredient bins and between feeders and batch hoppers, along with ducting to the collector (inside or outside facility).

The Most Common Way to Batch Ingredients for Rubber

What is the most common way to batch ingredients for rubber? This is typically called rubber compounding. What is compounding in rubber processing? Rubber compounding or formulation refers to the addition of certain chemicals to raw rubber in order to obtain the desired properties.