Blog

Upgrading Bakery Batching System

So you have an existing bakery ingredient batching system. You need help upgrading your ingredient batching system? Let’s examine an application where that took place.

Moving Batches from Point A to Point B

So you are going to purchase a custom-engineered ingredient batching system but are concerned about how to arrange for moving batches from point A to point B? Meaning, how to get the batched ingredients from the batching system to the mixer. Well that’s not too difficult, depending on the facility layout.

Protecting Grinding Mills

Grinding mills and classifiers operate at high speed and utilize bearings for proper and efficient operation. Protecting grinding mills from damage? Is it possible? Sure, there are some things that can be done.

Using Treated Peat with Crop Seed

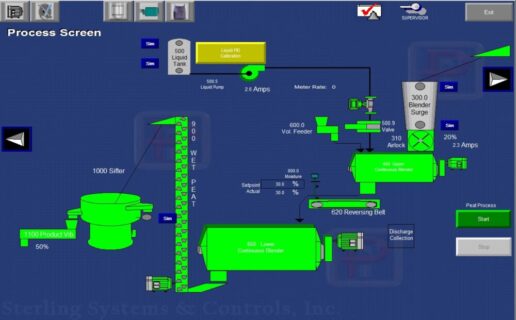

High crop yields require good nutrients, and the amount of nutrients delivered (like phosphate and nitrogen) can also make a big difference in crop yield. Nutrients can be added in different ways, one includes using treated peat with crop seed.

Rubber Chemical Batching Made “Automatic”

Sterling Systems has developed the capability for custom engineering rubber chemical batching systems that automate the ingredient batching of the rubber chemicals for the rubber compounding process. This system uses a hybrid ingredient bulk material batching system that can combine minor bin and bulk bag ingredient batching or just minor ingredient bins, Sterling Systems has been automating rubber compounding and replaced the slower, labor intensive manual batching with an efficient, fast and accurate automated system.

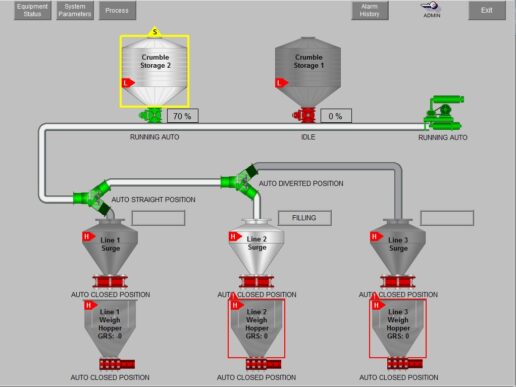

Automatic Ingredient Bread Batching System

Does your financial success rise and fall (pun intended) on your bread making skills? Sterling Systems can help you realize your current and long term goals. In this example case the bread batching system consists of both an automatic and a semi-automatic (operator made weighments) batching process.

Rubber Compounding

The first step in most rubber manufacturing processes is compounding. This requires the accurate batching of ingredients together for further processing.

Best Transition from Manual Batching

The best transition from manual batching is semi-automatic. Let’s discuss this just a bit. Manual Batching = Messy Lot Tracking, Weighing Errors, Unacceptable Scrap and Material Loss. First Step Solution = Semi-Automatic Batching.

Helping Seeds Engineering Services

Sometimes you need a helping hand. Helping seeds, as an industry, is something requiring expertise in technology and process.