Industrial Batching Systems

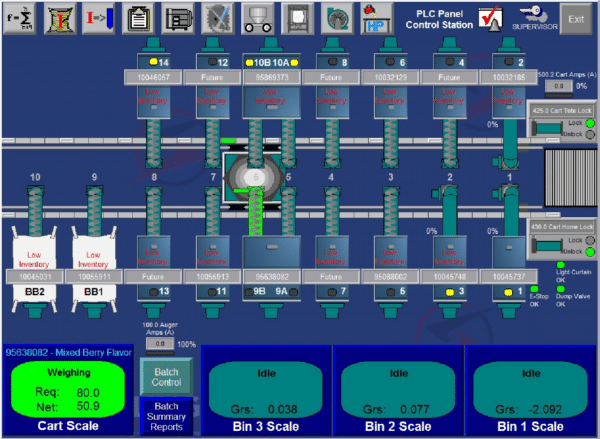

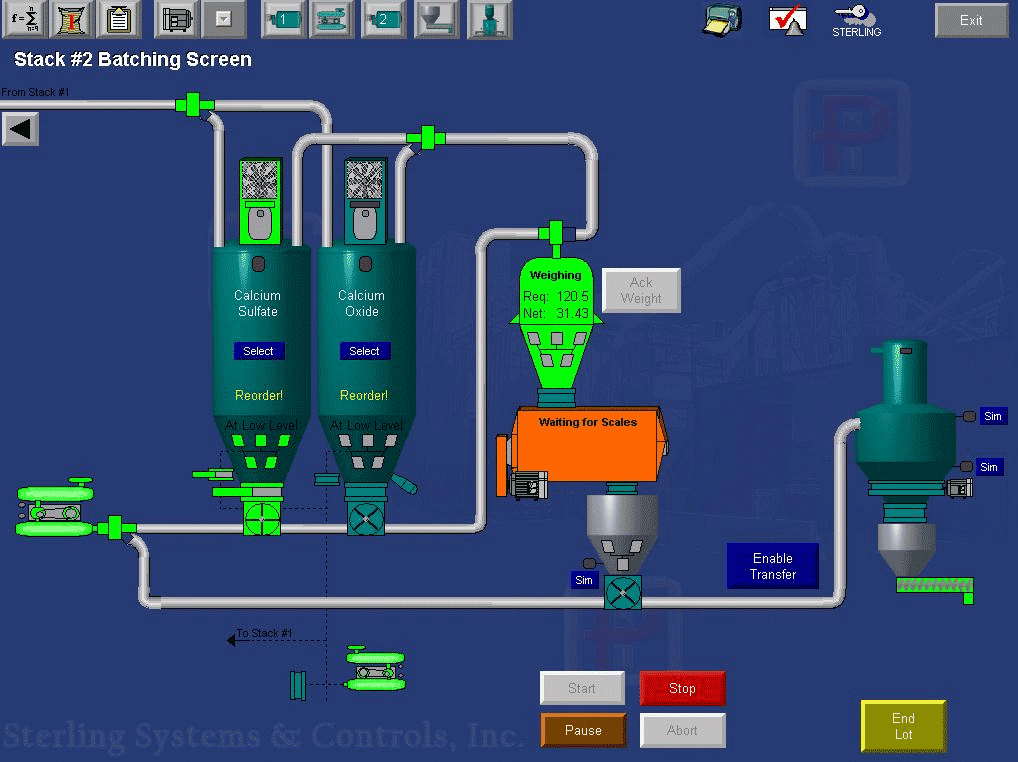

Sterling Systems & Controls, Inc. offers industrial batching systems and automation solutions for every aspect of the industrial manufacturing process involving both dry and liquid materials. Typical automation of industrial batching systems can also include raw material handling systems, such as pneumatic & mechanical conveying, liquid batching and metering systems, mixer and blending automation, minor & major ingredient weighing systems, bulk bag unloading systems, bulk bag filling/packaging, and packaging systems.

Types of Materials in Industrial Batching Systems:

Industries Served:

“Industrial” generally refers to anything other than feed, pet food, baking, and food processing industries.

- Plastic.

- Rubber.

- Steel.

- Automobile.

- Welding.

- Cement.

- Asphalt.

- Packaged Concrete.

- Sand Drying.

- Casting Recovery Systems.

- Ice.

- Wood.

- Paper.

Key Features:

- Scheduling.

- Formulation Management & Storage.

- Raw Material Management, Inventory and Usage.

- Material Parameters (Tolerance, Feeder Speed, Jog, Pre-act/Cutoff…).

- Lot Tracking (Barcode, RFID).

- Validation (Barcode, RFID).

- Equipment Parameters (Scales, Mixer, Dry Ingredient Feeders, Liquid Meters).

- Temperature Monitoring.

- Mixer Load Tracking.

- CO2System Automation.

- Finished Batch Tracking.

- Abnormal Condition Alarms and Tracking.

- Remote Process Status & Data Access Software (WebCentral).

- Troubleshooting & Diagnostics Features (Local & Remote).

- Bulk Bag Unloading.

- Bulk Conveying System Automation.

- Bulk Liquid Handling System Automation.

- Micro, Minor, Major Ingredient Automation.

- Semi Automatic: Manual Prompting & Weigh Station Automation.

- Mixer Automation.

- Packaging Interface – Yield System Automation.

- CIP (clean in place) System Automation.

- Conductivity Monitoring.