Mixer Control for Bakery

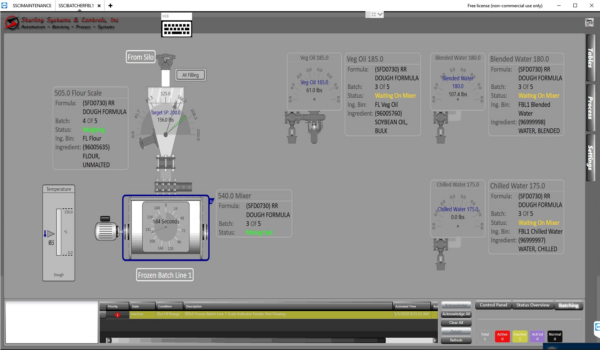

Sterling Systems & Controls, Inc. mixer control for bakery application includes sequencing and verification of operator interface steps at the mixer, to the automated ingredient tracking from receiving of raw materials to the finished batches of dough. The following highlights the different levels of process controls typically available for mixers, and specifically mixers for bakeries.

Sterling Systems & Controls provides mixer control design and equipment using Allen-Bradley PLC’s and industrial PC’s running customized Windows-based Sterling Systems & Controls automation software. Sterling Systems & Controls has more than 50 years of process and automation technology experience to ensure quality and efficiency in both hardware and software.

Mixer Control Options

Sterling Systems & Controls standard bakery batching process control can automate the mixer speed (fast and slow) through the recipe sequence instructions. The scale & mixer inlet gate is also controlled by the system. Sequencing can be adjustable or fixed. The bakery batching control will also monitor mixer bowl positions. Monitoring mixer bowl positions allows the batching control system to verify that an operator has lowered the mixer bowl to accomplish certain tasks as they are prompted through the batching sequence.

Such tasks as hand-add, bowl scraping, etc. will require that the mixer bowl has been raised or lowered to the required position and these steps, verified as part of the formula specification. The batch recipe and summary will ensure that each batch is efficiently and repeatedly produced to the formula specification. Please contact us for more information about mixer control and ingredient batching for bakeries.

Benefits

- Custom-designed SSCI.NET software batching application specifically for bakery mixing to meet your exact requirements.

- Integrated mixing control options with weighing and batching for dry and liquid ingredients.

- Comply with Food Safety requirements.

- Increased throughput & batch consistency.

- Compare Live Mix trends to saved Perfect Batch trends to compensate before dough is discharged.

- Easily scale recipe size based on flour draw.

- Can correct/repair batch consistency “on the fly”.

Typical Features

- Automatic and/or Semi-Automatic ingredient batching.

- Lot Tracking and Batch Validation.

- Control mixing of dry, liquid and hand-add ingredients.

- Programmable recipes.

- Ingredient tolerance control (+/-).

- Mixer bowl temperature monitoring.

- Mixer load control tolerance/history.

- Raw ingredient inventory and usage.

- Finished product batch/history.

- Virtually unlimited number of recipes and ingredients.

- Wide range of applications for type of mixer, size and configuration strategies.

- ERP system integration capable.

- Remote supervisory control available.