Custom Feed Mill Controls

Integrating various application modules into Custom Feed Mill Controls and automation systems requires great listening skills, process knowledge, and technical expertise. That’s why Sterling Systems & Controls, Inc. employs top-notch engineers in all disciplines required. We don’t use contract engineers. It takes a team skilled at working together to accomplish your objectives. This is but one example.

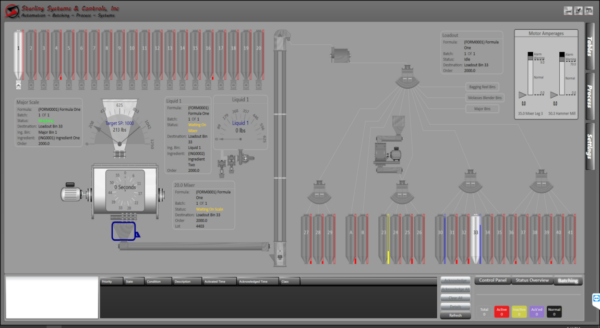

Custom Feed Mill Controls can include almost anything, from start to finish, generally Receiving, Material Transfer, Grinding, Batching, Pelleting, and Loadout are commonly provided. Sterling Systems & Controls proposed an Automated Feed Mill Control System with custom Feed Mill controls using a server-based system with virtual machines, thin clients, and a PLC (Programmable Logic Controller). This proposal was based on drawings provided by our customer and our detailed discussions to understand our customer’s objectives and requirements. It was decided that the areas to be automated were to include:

- Truck Scales Interface.

- Receiving/Transfer.

- Flaking.

- Grinding.

- Batching (Major/Minors/Liquids) with automatic routing to either bagging or load out bins.

- Pelleting.

- Automatic Truck Loadout.

The Custom Feed Mill Controls utilize a rack-mounted server, and rack-mounted PC’s running Sterling Systems & Controls Windows-Based Automation Software using a SQL Database (supplied by Sterling Systems & Controls) to collect and store data. The server is connected to an Allen-Bradley PLC (Sterling Systems & Controls is a recognized Allen-Bradley systems integrator) housed in the Feed Mill Control Panel. The PLC provides an Input/Output (I/O) interface to the field devices. Manual controls are accomplished using Sterling Systems & Controls software. All components used are non-proprietary and available from local suppliers.

The Custom Feed Mill Controls and automation system includes the Server, SQL Server, Thin Clients, UPS’s and printer. The customer provides Internet Access for updates and troubleshooting of the system by the Sterling Systems & Controls project engineers from their location. This saves our customers money, e.g. less downtime and the cost of travel expenses. The system incorporates ingredient and formula destination checks to ensure ingredients and formulas are not cross-contaminated while batching and transferring occur. The Custom Feed Mill Controls also include Sterling Systems & Controls standard batching features such as multi-tasking capability that allows the system to batch while editing or checking formulas, formula production/inventory, ingredients, ingredient inventory/usage and other main menu functions. The system automates the major bins, liquid feeders, scales, mixers, and the discharge of the mixers. Auto-Routing is also incorporated to meet specific customer objectives. The Batching application module monitors the finished feed/loadout tank levels and controls the finished feed discharging via pumps and valves.

WebCentral

Sterling Systems & Controls WebCentral supervisory control application software (for remote database access) is also included. This application software is installed on the database server and accessed through a web browser from any of the corporate computers that are connected to the same local area network as the database server. The WebCentral software application provides the capability to edit formulations, bin tables, and ingredient tables, and view and print historical data in the database without interrupting production and without requiring additional software to be installed on the corporate computers. This also achieved a major objective the customer had.