Grinding Feed Mill Automation

Feed mill automation can simplify operations and improve cost and throughput efficiency. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill process or a complete facility. We highlight the Grinding Feed Mill Automation application here.

Sterling Systems & Controls designs and provides equipment and software for custom systems using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems & Controls customized Windows-based Automation Software. Sterling Systems & Controls more than 50 years of Feed Mill process and Feed Mill automation experience ensures quality and efficiency in both hardware and software.

Grinding

The Grinding Feed Mill Automation process increases efficiency and improves conditioning in a feed production operation. Grinding performs particle size reduction for further processing of the material. Grinding creates more surface area, which aids in the digestion of the feed. In the grinding process, the fracturing of the solid material occurs, resulting in both an increase in material surface area and the dissipation of heat.

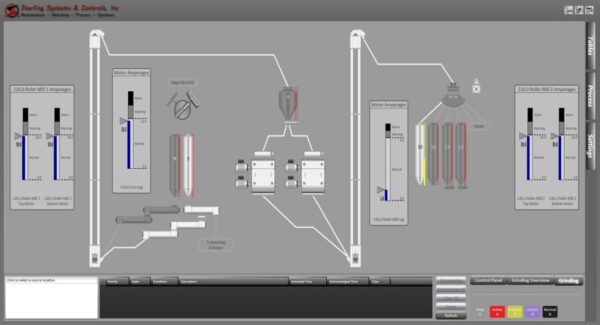

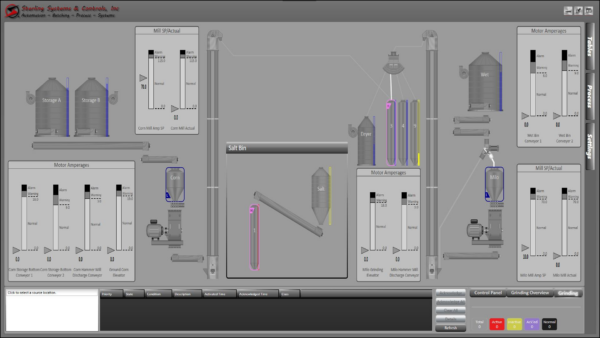

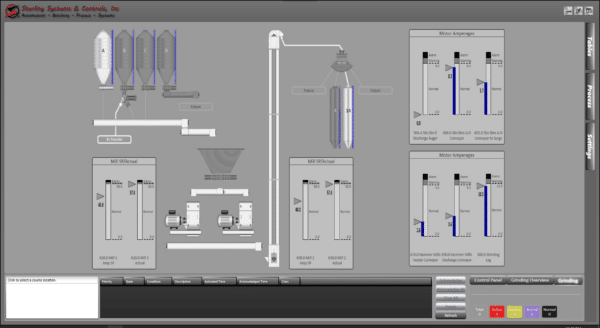

Whether you use a roller mill, Hammermill or something else in your process, Sterling Systems & Controls, Inc. automation and process control systems can automatically optimize its operation within the overall feed production process and automation system to meet a specific particle size requirement. This includes setting or programming Mill Type, Grinding Rate, Loss Factor and Source/ Destination Ingredient, along with providing feeder speed control based on the type of material, type of grinding mill, and the transfer of the material to the next part of your feed production process.

With the scheduling of the grinding process, the Grinding Feed Mill Automation system controls receiving and programs the grinding function, providing an accurate, schedule-driven automatic process with very little or no manual intervention. Superior scheduling and control allows your Feed Mill to generate higher process efficiencies, and eliminate more waste and contamination issues while delivering improved accuracy and superior product.

Benefits

• Higher accuracy and superior product.

• Automatic adjustment of Grinders to meet particle size requirement.

• Reduced waste and contamination.

• Runs Grinders automatically to keep destination ingredient bins full.

Typical Features

• Easily set Mill Type, Grinding Rate, Loss Factor, Source / Destination Ingredients.

• Automatic scheduling and transfer of materials.

• Maximizes throughput by running grinding mills to the most efficient load.

• Grinds whole ingredients and routes them to the correct bins, with little or no attention from an operator.

• Tracks maintenance minder data; hours, tons of usage.

• Mill monitors integrated into Feed Mill automation system.

• Blend multiple Source ingredients to produce a single ground Destination ingredient.