Batching Control System

Food manufacturing of almost all types includes the combining of a variety of ingredients into a “batch” prior to baking or processing. The entire process, especially key sections, needs to be controlled, and is commonly automated for efficiency and consistency in quality and cost. One aspect of the food manufacturing process automation is the Batching Control System. The food process automation system can control many aspects of the food manufacturing process. The Batching Control System is a key to business success.

If the food manufacturing process isn’t efficient and is hurting profits, an expert in process control and automation is needed to assist the food manufacturer. Sterling Systems & Controls was asked to help automate various aspects of a food manufacturer’s production, including the addition of an automated Batching Control System. In this case, two manufacturing lines needed to be controlled, one for frozen food and the other for “parbaked” food. “Parbaking” is a common process for bread or dough-based food products, and Wikipedia explains it well.

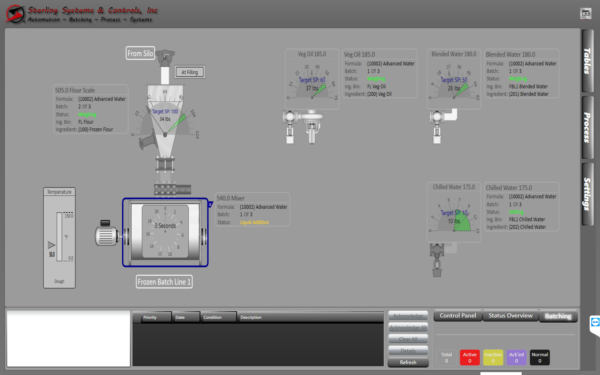

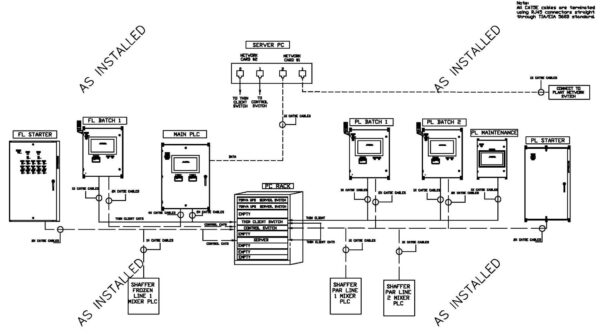

In this automated control system, control panels are provided for the control of the batching system feeding both production lines, and individual control panels for both the PLC’s and the starters/VFD’s involved with the ingredient batching production process. The “as installed” system architecture illustrates this and is just one example of a successful Batching Control System for food manufacturing. Some important functions of the system include the Recipe Sequence, Ingredients, Bin Assignment, Lot Table, Batching Schedule, Security Manager, Batching Process, and Mixer Control. Below are some example screens for these functions.

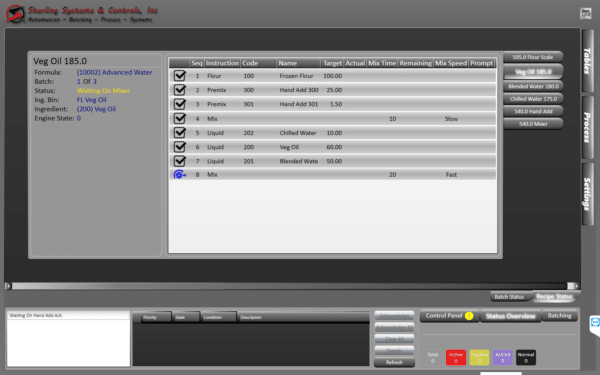

Recipe Sequence

The Recipe Sequence is used to create, view and modify steps that define how a formula is made.

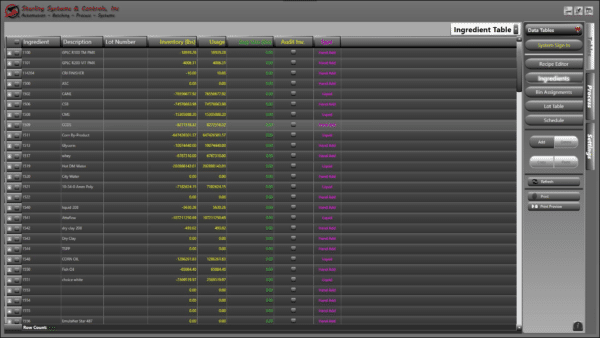

Ingredients

The Ingredients screen displays usage and inventory data for all ingredients. As the batching control system runs, the inventory is automatically reduced, and usage increases.

Bin Assignment

The Bin Assignment table is used to associate an ingredient code with a physical location in the system.

Lot Table

The Ingredient Lot Table displays each ingredient lot number, inventory, and associated ingredient code.

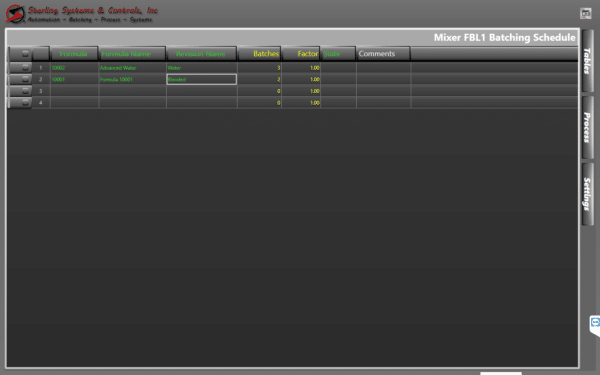

Batching Schedule

The Batching Schedule screen defines what the batching control system should make when it is started. Each mixer has a separate screen (if multiple mixers exists), and the operator can choose which one to view.

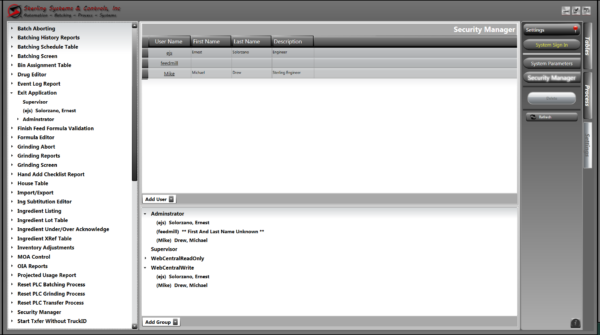

Security Manager

Access to the various functions and features of the system application is controlled by a flexible and powerful security system. The Security Manager can control which features or screens are protected and who can access those features and screens.

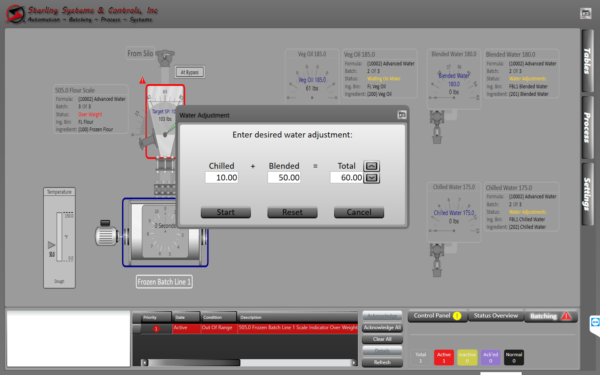

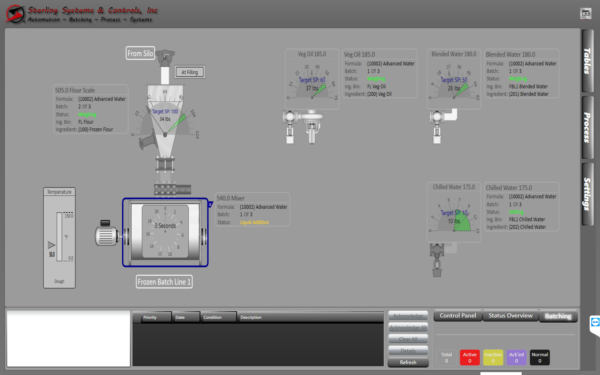

Batching Process

The Batching Process screens provide a graphical display of the equipment used in the batching process. It is divided into multiple sections, each with its own dedicated screen. Detailed information specific to the sections may include equipment, batching status and other information. Sections can include: Status Overview, Mixer(s), Scales, and Loadout.

Mixer Control

The Mixer Control screens show the bulk material mixer and liquid ingredient metering (if any).