Terminology

Navigating through the terminology used in industries concerning weighing, batching, mixing, process controls and automation can be like traversing a maze, with each company or industry having its unique vocabulary. At Sterling Systems & Controls, we recognize the confusion this can cause and aim to alleviate it through this dedicated section on our website. Here we endeavor to provide definitions and clear and understandable explanations of the various terms commonly encountered in industry discussions and on our platform.

As we embark on this endeavor, we understand that alphabetically organizing such a vast array of terms is essential for easy reference. However, when building this comprehensive resource, there may be instances where the arrangement is temporarily disrupted. We sincerely appreciate your patience and understanding during this development phase. Our ultimate goal is to create a resource that not only clarifies industry jargon but also enriches the knowledge of all our visitors, whether they are seasoned professionals or newcomers to the field. If you have suggestions for Terms to add to this resource please let us know.

A

Accuracy: In typical use in the processing industries for material weighing, ingredient batching, and controls/automation, the term “accuracy” is the degree of conformity of a measured or calculated quantity to its actual value or standard. It is the measurement devices absolute correctness.

Airlock: (a.k.a Rotary Airlock) In bulk material solids handling and processing an airlock,or rotary airlock, is a type of valve used for controlling the flow of dry bulk solid material that not only controls the feed rate of the bulk material, but also minimizes air leakage (pressure loss) between the equipment above and below the airlock valve where differing levels of pressure exist.

Alarm Management: The systematic handling of events considered “alarms” (usually abnormal events) to ensure that operators and other personnel are alerted to these critical conditions or equipment/process failures in a prompt and timely manner.

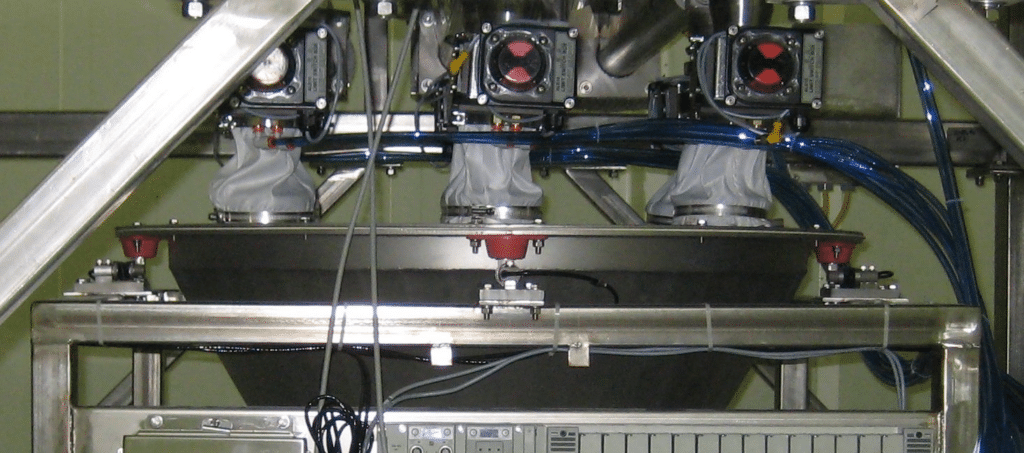

Auger Feeder: An Auger Feeder, a.k.a. Screw Feeder, is a type of dry material feeder commonly used in minor and micro ingredient batching systems to feed material from each ingredient supply bin to a weigh scale or scale hopper. The screw feeder feed rate can be adjusted based upon the screw or auger size, the number and shape of individual flights on the screw or auger, and the speed of the drive for the feeder.

Automation: Automation can be defined in a few different ways. But for our purposes here, automation is the application of technology in a custom-engineered manner to monitor and control a process of production, such as the production and delivery of various goods and services in a wide range of industries. Automation will perform tasks or processes that were previously performed manually by operators. Sometimes Automation is referred to as Process Control, which it is, but Automation can be the application of technology to automate things other than processes. Industries where automation is routinely employed include agriculture, food manufacturing, chemical production, refining, and many other industries.

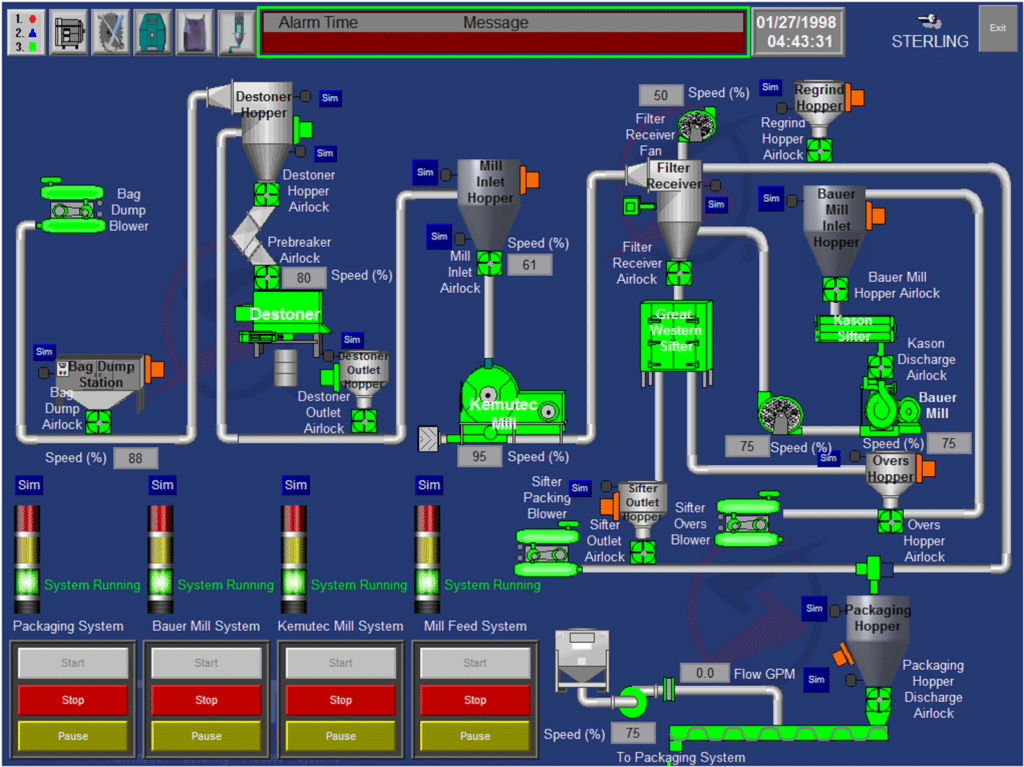

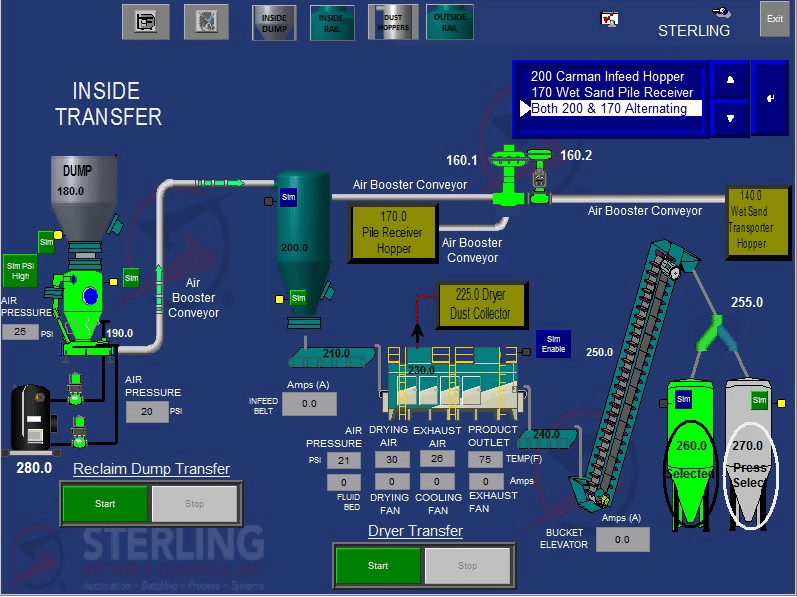

Automation System: An automation system includes the seamless integration of control systems, machinery, and processes to minimize operator/personnel involvement while maximizing operational efficiency and productivity. This typically involves the use of various technologies such as sensors, actuators, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems, among others.

Automatic: This terminology section will define the term Automatic in regard to a Batching System. A batching system has two functions which can be done either manually or automatically. These are the feeding of ingredients into a batch, and the weighing of each ingredient and the total batch. In a Manual process an operator performs these functions. In an Automatic system automation performs these tasks in some manner.

B

Bakery Stack-up: A term used in the baking industry batching system arena. Multiple components are stacked one on top of another to create the material batching and weighing system.

Banbury: A mixer type. Banbury is a registered trademark owned by the Farrel Corporation. Banbury is a type of mechanical mixer primarily used in rubber and plastic compounding, known for its ability to force the cohesion of these materials. Process control of a Banbury mixer is an expertise that few have, including Sterling Systems & Controls.

Batch Control System: The software/hardware systems in a Batching System that specifically are required for the management and control of the batching process to ensure ingredient proportioning and mixing. The Batching Control System is also responsible for collecting, organizing and managing all the data associated with ingredients and batch production for traceability and analytical usage.

Batch Rate: This generally refers to the rate at which batches of products or materials are processed or produced within a specific time frame. It can be measured in various units depending on the industry. Examples include items per hour, pounds or kilograms per minute, or gallons per day.

Batch Record: A batch record is the documentation that captures all of the critical steps in the process of creating the batch. This also will include the materials/ingredients used, weighments made during the batch creation, ingredient lots, etc. This is critical data that the batching control system captures and stores/manages.

Batch Size: The amount of material produced in a single batch. A batch typically includes multiple ingredients, may be dry or liquid ingredients, is prepared to a specific recipe or formula, and usually is created by weight.

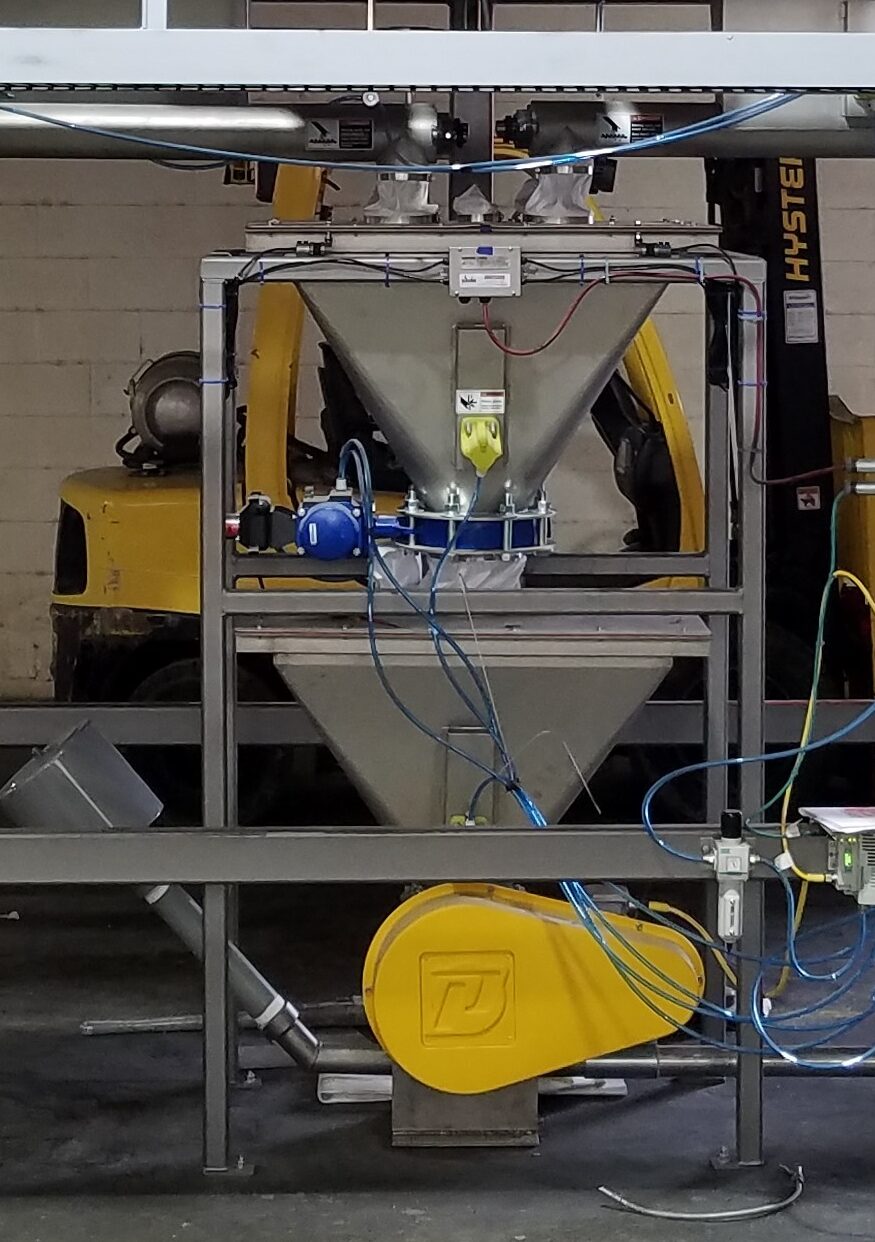

Batching System: In the process manufacturing industries such as feed, food and many others, a “batching system” is one in which the semi-automatic or automatic collection of multiple ingredient dry solids and/or liquids occurs. The dry and liquid ingredient materials are either automatically or manually fed into a collection container, automatically weighed, and then manually or automatically transferred to the next process step, such as a mixer, via mechanical or pneumatic conveyance. Batching systems may also be referred to as Micro Ingredient Batching Systems, Minor Ingredient Batching Systems, Bulk Batching Systems, Automatic or Semi-Automatic Batching Systems (automatic and semi-automatic refers to the feeding of ingredient materials), Material Weighing Systems, Material Batching Systems, Hand Prompt Batching Stations (referring to the system which prompts an operator to manually feed material ingredients into a batching container), and Kitchen Batching Systems.

Batching Stations: What is a batching station? The term “batching station” can be defined as the location for the operator interface to the batching control system. Usually, there is a single batching station (control panel) in a batching system, but sometimes there can be multiple batching stations.

Batch Weighing: The process of weighing a single or multiple ingredients according to a recipe/formula where a predetermined quantity of material is weighed and then processed or packaged.

Bearing Condition Monitor for Classifiers: Classifiers and Grinders are particle size reduction machinery. Classifiers and Grinders are rotating process equipment. As such they have bearings. These bearings are critical to the safe operation of the equipment. Bearing failure can result in equipment downtime and safety problems. Monitoring the status of the bearings and overall equipment function is what Bearing Condition Monitors do. Specific Bearing Monitors are available for the Prater Industries brand of particle size-reducing classifiers and grinders. These Bearing Condition Monitoring panels monitor vibration, acceleration and temperature and are invaluable for critical processes.

Bin: A “bin” is a container for material, typically for bulk solid materials rather than liquids (see “tank”). A bin typically has one or more outlets for removal of the material and usually a single inlet, though there could be more. Discharge of the material through the bin outlets is either by gravity or by some devices that promote flow or devices that assist gravity.

Bulk Bag: A bulk bag is also referred to technically as an FIBC, or Flexible Intermediate Bulk Container. These bags are containers to hold dry materials, powders and granular materials. They are made of flexible fabric, such as polyethylene or polypropylene. They expand to fit the dry material. They have an opening in the top and a discharge or outlet in the bottom of the bag. A wide variety of flexible bulk bag containers exist with differences in shape, inlet, discharge, etc. Filling and Emptying FIBC’s are accomplished with specialized process equipment custom-engineered and manufactured to fit the specific application requirement. These machines are often equipped with scales and weighing systems. Bulk Bag Filling Systems and Bulk Bag Discharge/Unloading Systems.

Bulk Material Handling: This is an engineering field involved with the design of equipment used for the handling of bulk dry materials such as those which are powdery, granular or lumpy in nature, and are stored in “heaps” in bins, silos, open piles, etc. Often bulk material handling systems are engineered for moving dry materials from one point to another. The ability of a dry bulk solid material to flow is a function of the material and the equipment handling it. An easy-flowing bulk solid material placed in the wrong piece of equipment can become difficult to handle. If it is placed in the correct equipment, it can flow reliably. Some methods can be employed to promote the flow or movement of bulk solid materials. Mixing and blending of bulk solids is an important processing step in many industries. Batching incorporates the feeding of dry bulk solid materials into a “batch” for mixing or other downstream processing.

C

Calibration: Adjusting or verifying the accuracy of a measuring instrument, such as a weigh scale or other weighing device/instrument, by comparing the output of the measurement from the instrument to some known standard(s).

Controls: a.k.a. Process Controls related to Automation.

Conveyor: A conveyor is a mechanical apparatus that transports material. Many different kinds of conveyors exist. For our context here we are talking about and defining conveyors that are used to transport bulk dry materials, powders, granular materials, etc. In bulk material conveyors there are generally two types, pneumatic and mechanical. Both pneumatic conveyors and mechanical conveyors are defined within this Terminology section.

Classifier: A classifier is a piece of process equipment that separates material based on a set of characteristics, such as particle size, density, etc. “Air Classifiers” provide a highly precise method for separating and classifying particles to the desired size and density. Classifiers are typically designed to provide ultra-fine separation and narrow particle distributions for dry bulk materials. Often air classifiers offer size separations in the range of 3 to 150 microns. They are ideal as a stand-alone process that includes a feeder and dedicated dust collection system. They are equally suited to “closed-circuit” grinding when coupled to a conventional milling system.

D

Decision Table: Refer to Rules Table.

Distributed Control System (DCS): A control system, typically computerized today, that is utilized to control and automate complex process systems incorporating multiple autonomous controllers/control systems distributed throughout the system with no central supervisory control.

Dynamic Weighing: A weighing process where the ingredient materials are weighed while they are in motion, often using conveyor belt scales or some form of continuous weighing system. The use of conveyor belt scales is common in many industrial applications where ingredients are batched into plastic bags/totes sequentially with relatively high batch rates, small batch sizes.

Drag Conveyor: No, this is NOT a conveyor dressed up as something other than what it is. It is a conveyor named for its method of moving bulk solid materials by dragging it from point A to point B. They can be used to move material in elevation as well as in linear motion. Typically, it consists of a drive chain and paddles or blades that capture and “drag” material along. One reason for using drag conveyors is they are more flexible in terms of the type of material they can move, wider range of bulk densities, particle size, etc. Typically the sizing of a drag conveyor depends upon:

- What the conveyor is to handle

- What the average particle size will be

- What the expected amount of material is that needs to be moved, such as described in Tons Per Hour

- How the drag conveyor will be loaded

- At what elevation the drag conveyor will discharge

- What is the horizontal distance from the center of the inlet to the center of discharge, etc?

Drawer-In-Housing Magnetic Separator: Also known as “drawer magnets”, these consist of rows of round magnetic tubes that are assembled into drawers contained inside a housing. The magnetic tubes of each row are aligned on alternating centers from the row directly above or below it. As the product flows into the top of the housing, it is forced to cascade in a Zig-Zag pattern from row to row over the magnetic tubes. This ensures maximum tramp metal capture since the product comes in direct and repeated contact with a magnet as it travels through the housing.

Dryer: A Dryer removes moisture to reduce or eliminate said moisture from a powder or other bulk solid. Industrial Dryers come in many forms or types including Fluid Bed Dryers, Rotary Dryers and Rolling Bed Dryers.

Dust Collector: Processing of powder materials can create airborne dust. This can be problematic in many situations and hazardous. From toxic to explosive dust, this problem can cause property damage, injury and loss of life. Therefore, when airborne dust can be created in a process it usually requires being contained and collected. This is common in material weighing and batching applications. A dust collector is used to collect and temporarily store dust from a process point.

E

in Minor Ingredient Batching System

F

Feeder: The word “feeder” is used as a noun within the context of batching systems. A Feeder is a device or person that moves ingredients in a batching system from the ingredient container to the weighing scale. Automatic batching systems use automated feeders such as screw (auger) type or vibratory type feeders. In semi-automatic batching systems or manual batching, a person or operator is used as the “feeder”. Usually the operator uses a scoop to move an ingredient from its container to a weighing container on a scale.

Fieldbus: A digital communication protocol used in industrial automation to connect field devices (sensors, control elements, etc.), without having to connect each device individually to the controller or control system network.

G

Grinder: The term Grinder in this industrial perspective is a generic reference to a piece of process equipment that reduces the particle size of a bulk solid material. There are several different types of “Grinders”, each defined by some aspect of its method of operation, such as a Hammermill, an Air Classifier, a Ball Mill, Roller Mill, Pin Mill, Jet Mill and Colloid Mill. Some go beyond just particle size reduction, such as a classifier.

H

Hammer Mill: A Hammer Mill is one of the oldest particle reduction machines available today. A Hammer Mill consists of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. The bulk solid materials to be milled or reduced in particle size are struck by these “hammers” (rectangular pieces of hardened steel), which rotate at high speed inside the chamber. These radically swinging hammers (from the rotating central shaft) move at a high angular velocity causing brittle fracture of the bulk solid material.

Hand Prompt Batching System: Also known as “Hand Adds”, a Hand Prompt Batching System (or batching station) is a semi-automatic batching system. Refer to the “semi-automatic” definition further below. Offering the many benefits of ingredient batching systems, the hand prompt system includes ingredient lot tracking, automatic weighing of operator-added ingredients within a user-programmable tolerance, formula creation and storage, and inventory tracking. The hand prompt batching system is entry-level or the least expensive of automated ingredient batching systems but offers many important features and several high-end options. More information.

HMI (Human Machine Interface): this serves as the interface between an operator or other personnel (human) and a machine or control system. This device allows operators to interact and monitor the equipment/system operation through a graphical representation of the equipment/process, indicators and controls. The HMI plays a critical role in industrial automation.

I

Industrial Magnetics: Industrial Magnetics, Inc. manufactures magnet solutions specifically for tramp metal removal from bulk solids. Industrial Magnetics provides many off-the-shelf industrial magnet products but it is their ability to provide customer-specific solutions to unique problems that sets them apart from others in the industry.

Integration: The process of combining different subsystems or components into one larger system. Example: ERP systems are excellent at processing financial and other core business processes such as HR, supply-chain management, sales, and CRM. Process control systems (PCS) are superb and better at data collection and organization, interface with sensors, and control of critical process oriented manufacturing systems. ERP systems and PCS serve distinct but complementary roles in modern manufacturing and industrial environments. ERP systems focus on managing business processes and resources across the organization, while PCS are dedicated to real-time control, automation, and optimization of industrial processes and equipment. Integrating these systems effectively will enhance operational efficiency, decision-making capabilities, and overall business performance.

J

K

Weight of Scale Hopper Application

L

Level Sensor: a.k.a. Level Control, Bin Level Indicator. A level sensor can be either a point or continuous level measurement device. Point-level sensors monitor for the presence or absence of material in a bin at a predetermined point, such as a high level or low level. Usually in batching systems level sensors are of the point type and are used for monitoring low-level conditions in ingredient bins. Continuous level sensors measure the continuously changing level of material, up and down, as the material in a bin, tank or silo vessel goes up and down with material usage and resupply.

Load Cell: A load cell is a sensor used to measure force or weight. In most cases in bulk material storage, handling, and processing they are used to measure weight. A load cell converts the mechanical force applied to it into an electrical signal that can be measured and analyzed. Load cells are commonly used in industrial scales, ingredient batching machinery, and testing equipment to ensure accurate weight measurement.

Lump Breaker: Sounds ominous. What is a lump breaker? It’s just what it sounds like, a piece of process equipment used to break “lumps” in the flow of dry solid materials. They are used to break up materials that tend to clump because they are hygroscopic, meaning the particles tend to absorb moisture and then bind together and create larger particles too big to flow easily. These lumps or clumps can block flow streams and must be broken up. A lump breaker is usually a form of a rotary airlock valve, a.k.a. lump crushers. They are a form of particle size reduction equipment. For more information see this Lump Breaker web page.

M

Machine Vision: Technology for acquiring and interpreting images to guide automated processes, such as quality inspection or robot guidance.

Manual: In the batching function, a “manual batching” system is one that uses an operator to feed ingredients into a batch container on a scale for weighing, and also the operator manually moves the completed batch in the batching container to the next step in the process which is typically a mixer and dumps the batched ingredients into the mixer. The feeding of ingredients and the movement of completed batches are done manually, by an operator.

Metal Finish: Refer to “Surface Finish Grades”.

Micro: This term is generally used in describing the general weighment size for an automatic batching system. In an automatic batching system, the ingredients, based on the chosen formula to be made, are fed from the ingredient supply bin to the appropriate scale hopper for weighing an accurate amount according to the formula being run. A “Micro” weighment (refer to the definition of “Weighment”) is generally anything less than 50 lbs (22.7 kg). Often weighments are as low as several grams and the scale hoppers can be relatively small. The term “micro” regarding ingredient batching systems is often generically used in the Feed industry regardless of weighment size.

Minor: This term is generally used in describing the general weighment size for an automatic batching system. In an automatic batching system, the ingredients, based on the chosen formula to be made, are fed from the ingredient supply bin to the appropriate scale hopper for weighing an accurate amount according to the formula being run. A “Minor” weighment (refer to the definition of “Weighment”) generally runs from 50lbs (22.7Kg) up to around 150lbs (68.2Kg). The term “minor” in regard to ingredient batching systems is often generically used in the Food and Baking industry regardless of weighment size.

N

O

P

Particle Engineering: This is best understood by review of a blog post from a company that is a leader in particle engineering and size reduction, Prater Industries.

PID Control: PID is an acronym. It stands for Proportional-Integral-Derivative. PID is a control mechanism used to regulate process control systems, typically pressure, temperature, flow, etc. PID algorithms are embedded within single-loop, PLC, PC-based control, and DCS systems. Each term, P I and D, are adjustable to effect different results in the control of a process variable to a setpoint. For further study refer to PID Controller.

Pipe Magnets: These devices are a magnetic separator for pipelines. They are used to remove ferrous contaminants (such as iron particles) from liquids or dry bulk materials flowing through pipelines. This device consists of a magnetic tube or rod encased in a stainless steel housing. As the liquid or dry material flows through the pipeline, the magnetic tube attracts and captures ferrous particles, thereby preventing them from entering processing equipment downstream. Pipe magnets provide product protection for many industries, including flour, feed and grain, food processing, chemical resin, plastic processing, and more.

PLC: PLC is an acronym. It stands for Programmable Logic Controller. The PLC is an automation and control component. It was first developed in 1968 and called the Modicon 084 and used by General Motors. At first the PLC was used for “logic” on/off open/closed control functions. As the PLC evolved it incorporated PID control and analog inputs/outputs, as well as its digital input/outputs. Today the PLC is manufactured by several global manufacturers and is incorporated into most all process control systems in a wide range of agricultural and industrial applications.

Process Variable: A measurable quantity in a process, such as weight, temperature, pressure, flow rate, etc. that needs to be monitored and/or controlled as a part of the automation and control system for a manufacturing process.

Batching System

Pneumatic Conveying: Simply put, pneumatic conveying is the conveyance of dry material powder or small granular materials using air as the motive of transport. Various powder materials, such as flour and cement powder, and granular materials, such as plastic pellets, can be conveyed using pneumatic transport. There are two forms of pneumatic conveying, i.e., the dilute and dense phases. As stated, Dilute and Dense refer to the phase or state of the dry material within the pneumatic conveying lines. Dense phase pneumatic conveying will move the material in densely packed slugs. The dilute phase moves the material entrained within the air stream in a relatively uniform stream from the material supply source.

Pneumatic conveying can use positive or negative pressure. Negative pressure systems are vacuum systems, and positive pressure pneumatic conveying systems use a positive pressure blower. Pneumatic conveying within a batching system is used to move completed batches to the next process step, typically to a mixer. Most often negative pressure vacuum systems are used in batching systems.

Precision: The degree to which repeated measurements under unchanged conditions show the same results. Precision is about the consistency of measurements and, statistically speaking, how tightly clustered the results are around the true value. It is related to, but not the same as, Repeatability. Repeatability is about the ability of a measuring system to obtain the same result when measuring the same quantity multiple times under the exact same conditions.

Pulses: Pulses are the edible seeds of plants in the legume family. Pulses grow in pods and come in a variety of shapes, sizes and colors. The United Nations Food and Agriculture Organization (FAO) recognizes 11 types of pulses: dry beans, dry broad beans, dry peas, chickpeas, cow peas, pigeon peas, lentils, Bambara beans, vetches, lupins and pulses nes (not elsewhere specified – pulses that don’t fall into one of the other categories).

Q

R

Recipe Management: This is the systematic process of creating, managing, and controlling recipes or formulas used in a variety of process manufacturing industries such as food, baking, pet food and treats, plastics and rubber compounding, etc. It involves the documentation, standardization, and optimization of ingredient quantities, processing steps, and other parameters necessary to produce a consistent and high-quality product. Recipe management is critical for producing consistent, high quality product profitably. This is important as it leads to customer satisfaction and brand loyalty.

Resolution: In relation to a measurement of a process variable such as weight, level, temperature, etc., the resolution is the smallest value or number that can be displayed or measured by the device. For example, a scale that has an accuracy of 0.25% may be said to have resolution of 0.001lbs. Its “absolute correctness” (Accuracy) is to within +/-0.25% of reading, and the value can be display or resolved (Resolution) to 0.001lbs.

Robotics: This is a sub-category of technology involving the design, construction, operation, and use of robots for automation of production processes. Robots are programmable machines that can perform repetitive tasks autonomously.

Rotary Airlock Valve: Refer to “Airlock”.

Rubber Compounding: Rubber is typically made by mixing a variety of ingredients designed to create a specific compound. The formula consists of various chemicals, including cross-linking agents, reinforcements, antidegradants, and colorants. Important in rubber compounding is batching the various chemical ingredients together. More information on rubber batching can be found on this site.

Rules Table: A Rules Table, a.k.a. a Decision Table, in process control software applications, such as Batching, is a set of rules with identified qualifications. In a Batching control system, the Rules Table feature will check Formulas to run against a set of Rules and verify if any are violated before the formula can be run. If any Rules in the Rules Table are violated, the formula cannot run.

S

Data Acquisition

SCADA: This is an acronym. It stands for Supervisory Control and Data Acquisition, refers to a system of software and hardware that is used to monitor and control industrial processes in real-time. SCADA systems gather and manage data from sensors, control devices, and equipment. This allows operators to monitor equipment and process conditions, control processes remotely, and make more informed decisions. They are crucial control and data management systems in process industries for optimizing operations, enhancing safety, and ensuring efficiency.

Semi-Automatic: A semi-automatic batching system differs from both the automatic and manual systems. It is a combination of the two. The semi-automatic batching system will automatically provide step-by-step instructions to an operator for creating a batch. The system automatically controls the process of proceeding from one step to the next by weighing and comparing the required amount and ensuring that the correct material has been used/added. The operator will feed each ingredient from its respective bin/box/container to the batch container for weighing on a scale controlled by the system. Once a batch is completed and verified by the system, an operator manually moves or transports the batch container to the next step, typically to the mixer.

Surface Finish Grades: The roughness and quality of the surface finish of metal that is in contact with the customer material are critical in many industries, be it an ingredient, final product, liquid, or dry material. Industries such as food and pharmaceuticals require specialized finishes. Please Contact Us for more information about surface finishes and what can be provided for our equipment and systems.

T

Tank: A “tank” is a container for material, typically for liquid materials rather than solids (see “bin”). A tank typically has one outlet to remove the liquid and usually one or more inlets. Discharge of the material through the tank outlet is either by gravity or pressure/pumping.

Tank Calculator: A tank calculator aids in calculating the capacity of a tank, whether a bulk tank or a liquid tank. There are several types of liquid tanks, including flat bottoms, slope bottoms, hopper bottoms, horizontal designs, and dish bottoms.

Tare Weight: This is the weight of the empty container or packaging that will hold the material being weighed, subtracted from the gross weight so as to determine the net weight of the material or ingredient(s) added to the empty container/packaging.

Toll Processing: This is the process by which various processing functions can be performed by a third party for a charge. These processing functions could be Sifting, Milling, Grinding, Lump Breaking, Classifying and even Compacting. See the video here on Toll Processing.

Tramp Metal Separation: This magnetic separation equipment removes ferrous and non-ferrous metal contaminants from dry or liquid product flows. It includes the use of magnets for gravity-fed flow (inside and outside the flow stream), conveyor-fed flow, pneumatic line flow, liquid line flow, and specialty application flow metal separation.

U

V

V-Mag: The V-Mag is a container on wheels used typically in the meat processing industry but also in many other segments of the food and pet food industry, carrying primarily dry materials for mobility. Ingredients can be “batched” into V-Mag containers or ingredients can be dumped from large bulk containers, like FIBC bulk bags, into the V-Mag container for movement throughout the processing plant.

Valve: A Valve is a mechanical device that regulates the flow of a dry or liquid material. The flow can typically be ranged from 0-100% by a valve. There are several different types of valves, depending on the application. Some are used exclusively for dry materials like powder or granular solids. Others are specifically designed for use with liquids. Common valves for regulating the flow of dry materials like powders are the Rotary Airlock Valve, Butterfly Valve (designs for liquids as well), Slide Gate, and the Iris Valve.

W

Weighing System: A weighing system combines various components and automation to provide a self-contained system that allows operators to weigh and batch various materials or ingredients according to a recipe or formula. It can be semi-automatic or automatic, a.k.a. a Batching System.

Weighment: No Terminology section would be complete without this specialized term. A weighment is the weight measurement of a given item, ingredient, batch, etc. To determine the scale requirements for ingredients, it is often necessary to know what the minimum and maximum weighment is for each ingredient. This means identifying the minimum and maximum weight value of a specific ingredient. A weighment can be thought of as a single weight measurement value.