Software Applications

Custom Automation & Data Solutions

At Sterling Systems & Controls, software is not just an add-on — it’s ingrained in our DNA. We custom-engineer mission-critical software applications for every solution we deliver, ranging from batching and asset monitoring to ERP integration and supervisory control.

As a certified Allen-Bradley systems integrator, we leverage modern technologies like Microsoft .NET for PC systems while ensuring robust integration with PLCs, databases, HMIs, and cloud or enterprise layers.

Why Sterling’s Software is Different

1. Modular & Scalable Architecture

We don’t force you into monolithic “one-size-fits-all” systems. Our SSCI.NET architecture supports modular deployment: only activate what you need and scale later as your facility grows.

2. Client / Server & Virtualization Ready

Our architecture supports distributed systems, virtualization, high availability, and disaster recovery strategies.

3. Future-Proof & Secure

We build systems to run reliably on Windows 10/Server environments and use modern encryption (AES-128) for database and control channel traffic. Email/text triggers, alarm management, and layered security are built in.

4. Smooth ERP / MES Integration

We support flat file exchange, database connections, and other interface methods to integrate seamlessly with systems such as FMM, MAS, Max-A-Mix, ROSS, Brill, Summit, AgVision, and more.

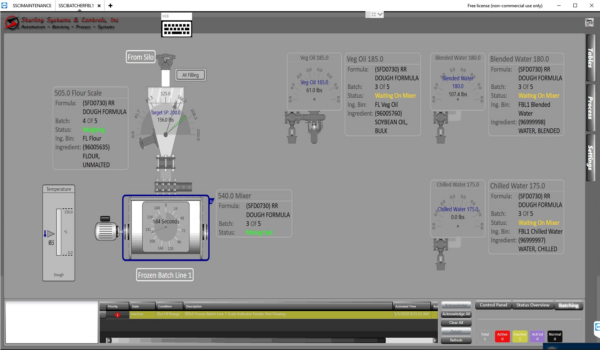

5. Usable & Intuitive HMI Design

Our operator interfaces are built based on ISO 11064, ISA101, ANSI/ASM, and other best practices in human-machine interaction. We carefully design for clarity, reduced operator fatigue, and fast error recovery.

6. In-House Control & Support

We design, code, test, and support all software internally — aligned with our mechanical and electrical teams. That means response time is fast, and continuity is ensured.

Example Use Cases & Industry Applications

Batching & Formulation Control — Automated micro, minor, bulk batching with full ingredient lot traceability, validation, operator prompts, hand-prompt systems, hybrid batching, and recipe versioning.

Pellet Mill Control & Monitoring — Real-time adjustments based on current, moisture, temperature, plug detection, and smart feedback loops.

Supervisory Dashboard & Remote Access — Browser dashboards, plant KPI monitoring, data exports, trend analysis, remote alerts.

Maintenance Scheduling & Repair Logs — Asset health tracking, preventive tasks, inspection records, OEE calculations.

Bulk Material Inventory, Sand Handling & Process Tracking — e.g. our SandTrack™ solution for storage and distribution of fracturing sand.

Getting Started / Migration Path

Assessment & Audit – We audit your existing software (if legacy) to determine gaps, risks and migration paths.

Architectural Design – We propose a software architecture: modules, client/server layout, redundancy, ERP interfaces, and security.

Incremental Migration or Greenfield Deployment – Whether you’re upgrading one line or deploying plant-wide, we modularize to reduce downtime.

Testing & Factory Acceptance – In-house system testing and customer validation (FAT) before delivery.

Commissioning & Training – On-site or remote commissioning, walkthroughs, operator training, and documentation.

Ongoing Support & Enhancements – 24/7 support. Our engineers are familiar with your system and can help adapt it over time.

Core Software Domains & Modules

Below is an overview of key software capabilities we deliver (modular and scalable to your needs):

| Software Domain | Description (AEO-Optimized) | Key Benefits |

|---|---|---|

| Automation Software Upgrade (FreshStart™) | Modernizes outdated automation systems such as MS-DOS or older Windows-based controls into Sterling’s modern .NET framework. Supports batching, mixing, grinding, pelleting, and alarm management. | Extends system life, reduces downtime, improves reliability, and adds secure remote supervisory control. |

| Process Controls & Automation | Provides fully customized PLC, HMI, and SCADA programming to automate manufacturing processes such as mixing, conveying, batching, and loadout operations. | Improves efficiency, consistency, and safety while enabling flexible process sequencing and data tracking. |

| Feed Mill Automation | Integrates control across the entire feed mill — from ingredient receiving to batching, pelleting, and loadout — using Sterling’s proven control logic. | Delivers higher throughput, better recipe accuracy, and full traceability for regulatory compliance. |

| Preventive Maintenance (PMPlanR™) | Maintenance planning software that builds an asset register, schedules inspections, and tracks work orders and service records. | Increases equipment uptime, lowers repair costs, and supports predictive maintenance strategies. |

| Supervisory Control (WebCentral™) | Web-based supervisory interface providing remote access and control through a standard browser without additional client installations. | Enables real-time monitoring, system management, and alarm response from any location. |

| Data Management & Traceability | Tracks ingredient lots, batch records, and inventory movements with seamless connectivity to ERP or MES systems. | Enhances quality control, compliance reporting, and operational transparency. |