Process Controls & Automation

Transforming Feed Mill Processing with Automation

Enhancing the efficiency and productivity of feed production is crucial for supporting livestock farming and ensuring a stable food supply over the coming decades. To address this challenge, feed mill automation has become increasingly important. By integrating advanced software with traditional hardware, automation improves feed production processes, streamlines operations, and boosts productivity. These advancements also contribute to greater sustainability and reduce environmental impact.

From Machines to Metrics

Sterling Systems & Controls engineers complete process control and automation systems—whether you’re upgrading a legacy line or building a new facility. From mixers, conveyors and feeders to full plant-wide automation with MES/ERP integration, our turnkey solutions bring better uptime, stronger data, and fewer surprises.

Why It Matters

Processes without controls lack repeatability, traceability and audit-readiness.

Sterling fixes that by making your controls architecture part of the process, not just an add-on.

Un-managed legacy systems lead to undocumented changes, unsupported software, and production risk.

Disconnected machines prevent holistic monitoring and cause data blind spots.

Core Capabilities

- Custom control panels (UL-listed USA/Canada) combining PLC, HMI, drives, safety and I/O.

- PC-based or .NET applications with modern architecture, SQL database, thin-client HMIs, and visualization.

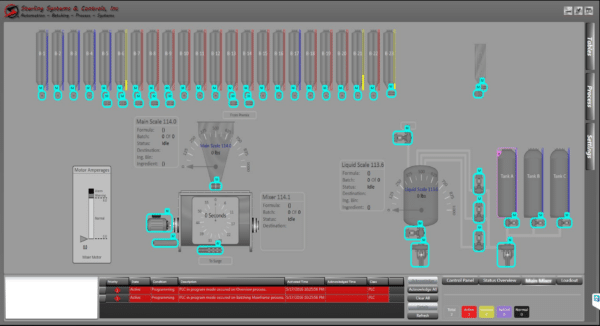

- HMI/SCADA systems designed for operator clarity, minimal training and responsive alarms.

- Process integration (batching, weigh systems, conveying, loading/unloading, mixers) across solids, liquids and bulk materials.

- Full lifecycle services: requirements definition, engineering, build, commission, training and long-term support.

Typical Applications

- Pneumatic/Mechanical conveying: loading, unloading, transfer.

- Mixing/blending, particle reduction, dryers, packaging lines.

- Truck/rail loading/unloading, compaction, bulk solids handling.

- OEM equipment controls and lines for bake-food, feed, pet-food, chemicals, plastics.

Upgrade or New Build?

Whether you’re preserving legacy hardware (and its quirks) or starting fresh, we tailor the solution:

- Upgrade path: retain mechanical equipment, modernize controls/software, clean up code and reporting.

- New build: full system from panel to PLC/HMI to data architecture, documented and scalable.

Ready to control more than just equipment? Let’s map your process controls and automation architecture—so you get data you can trust and operations you can scale. Request a quote or schedule a discovery call.

Frequently Asked Questions

What does Sterling mean by process controls and automation?

Sterling engineers complete controls and automation systems that coordinate equipment, software, and data flow across a manufacturing process. This includes custom control panels, PLC/HMI or HMI/SCADA platforms, and system integration designed to improve repeatability, traceability, and operational visibility.

What equipment and processes can Sterling integrate into a controls system?

Sterling integrates controls across batching systems, material weighing, conveying, mixing, loading and unloading, and other bulk material handling operations. Applications commonly include transfer systems, blending, particle reduction, drying, packaging lines, and truck or rail loadout.

What control panel and software capabilities does Sterling provide?

Sterling designs and manufactures custom control panels, including UL-listed panels for the United States and Canada. Systems may include PLCs, HMIs, drives, safety components, and I/O, along with PC-based or .NET software applications, SQL database integration, and modern visualization platforms.

Do you design operator-friendly HMI or SCADA systems?

Yes. Sterling develops HMI and SCADA interfaces focused on operator clarity, alarm management, and ease of use. Systems are designed to reduce training time while improving response to process conditions and operational events.

Should an existing control system be upgraded or replaced entirely?

Sterling supports both modernization and new system development. Upgrades typically retain existing mechanical equipment while improving software, control logic, and reporting. New systems provide a fully engineered solution from panel design through PLC/HMI architecture and documentation, allowing for future scalability.