Automation Software Upgrade

What is FreshStart™?

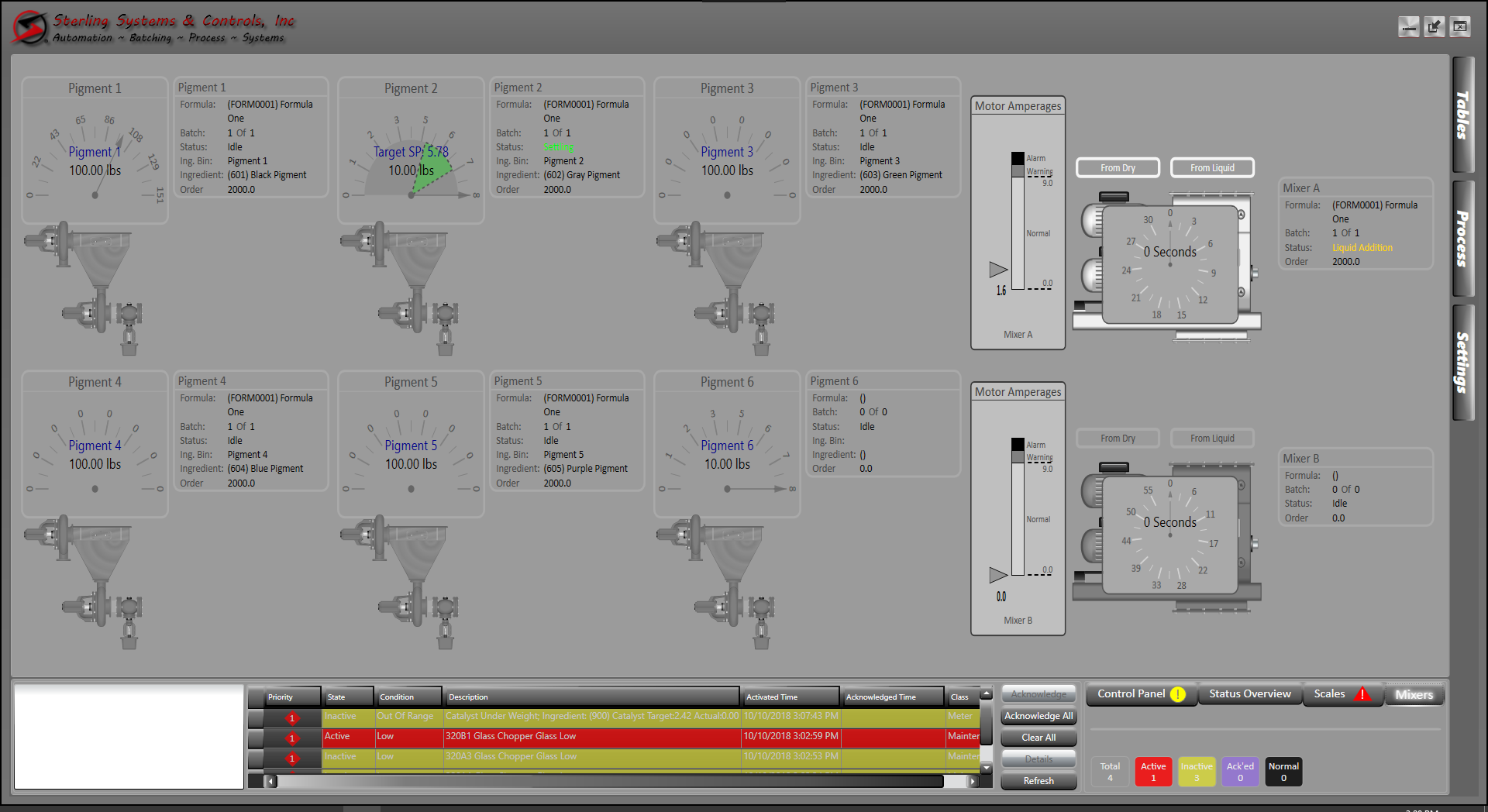

FreshStart™ is a technology program for automation software upgrades designed specifically for your Sterling Systems & Controls, Inc. legacy PC-based software. Do you have automation software applications including batching, mixing, grinding and much more, designed for and operating on MS-DOS, Windows XP, Windows 7, and Windows 8/8.1? Your company or industry does not matter. If you currently use the state-of-the-art Microsoft .Net-based software applications from Sterling Systems & Controls, great! If not, and you currently use our legacy PC-based software, the FreshStart technology upgrade is for you!

Reasons for Automation Software Upgrade

- Scalability. The modular design of the Sterling Systems & Controls state-of-the-art SSCI.NET-based software can easily grow as your manufacturing process grows, which helps reduce automation software upgrade costs. This is not possible with your old legacy software (MS-DOS, Win XP, Win 7, Win 8/8.1 based).

- Various modules are available. This currently includes Batching, Transfer, Receiving, Grinding, Pelleting, Loadout, Hand Prompt, Alarm & Events, PMPlanR™ Preventative Maintenance, and WebCentral™ Remote Supervisory Control.

- The software can run on Windows 10 Pro OS and future releases. Windows Server 2016 or later can be used. Web access can run on most modern browsers either on desktop or mobile devices. There is no chance of incompatibility issues in future releases.

- The latest and most state-of-the-art Microsoft and Allen-Bradley technologies are used, thereby providing the latest security and the very best user experience and features possible.

- SQL Server, both the Standard and Express versions, is utilized. This allows for systems of both large (Standard) and smaller (Express) database sizes.

- Numerous options of ERP interfaces are available. ERP interfaces via flat file transfer or database interface can be accommodated, including but not limited to FMM, Brill, Summit, AgVision, MAS, ROSS, Max-A-Mix, and more.

- Multiple monitor support on a single application. The state-of-the-art SSCI.NET software from Sterling Systems & Controls has a modular architecture. Therefore, you can have multiple instances of it running on a single PC or multiple PCs without conflicts or data corruption. This can be a huge benefit of flexibility over your legacy software. This complies with ISO 11064 standards for Control Center Design.

- The latest SSCI.NET software is a distributed architecture. This Client / Server based architecture is great for both large systems, and the standalone architecture for small systems. It allows the system to easily grow. Our Services, Database, WebCentral and PMPlanR software hosted on a server machine can be kept out of the plant floor and located in an atmospheric-controlled environment thus increasing reliability. The operator interface terminal can be a thin client and is located on the plant floor.

- Capable of running on virtual machines, which helps to increase fault tolerance and provide high availability.

- 3rd party communications capable from manufacturing to enterprise tiers continue to be supported.

- DCS disaster recovery options are available. Any Virtual Machines that are created and used can be backed up into a file server, cloud, or a backup server. If a second identical server on the network is used as a backup it can take over without interruption if the first server fails. If the VM’s are backed up to a cloud and the primary server goes down due to catastrophic failure, the system can easily be recovered once the primary server is back online or replaced.

- Enhanced Security. Database and control transport data traveling between points are encrypted using the AES 128bit algorithm. Legacy software is written under an older platform and development software, which are all obsolete by today’s industrial standards.

- Enhanced Alarms and Events. Email and Text notifications can be provided in SSCI.NET software, not in legacy software.

- Operator Interface Software Conforms to ISO 11064, ISA101, ANSI, and ASM Standards and Practices for:

- Reduced Eye Fatigue; counteracts “tunnel vision” under stress.

- Reduced Errors and Misinterpretations; superior accuracy during abnormal conditions.

- Data Shown in Highly Contextual Form; better and faster decision making.

- Information is Organized and Intuitive; reduces operator memorization requirement.

- Multiple Monitors; superior operations where more than one person can operate/monitor the system.