Controls & Automation

Controls and automation systems coordinate how industrial processes operate, communicate, and respond to real-time production conditions. Sterling Systems & Controls designs and implements controls and automation solutions that help manufacturers improve accuracy, reliability, and visibility across their operations.

Sterling’s controls and automation capabilities support both new system deployments and modernization of existing platforms. Solutions are applied across batching, material handling, processing, and packaging environments where dependable control logic, operator interfaces, and system integration are critical to consistent production.

Rather than focusing on individual components alone, Sterling approaches controls and automation as part of a broader operational framework—ensuring software, hardware, and process logic work together to support long-term performance and maintainability.

Controls & Automation Capabilities

- Sterling provides a range of controls and automation services that can be applied independently or combined to support larger system objectives. Capabilities include:

- PLC programming and control system development

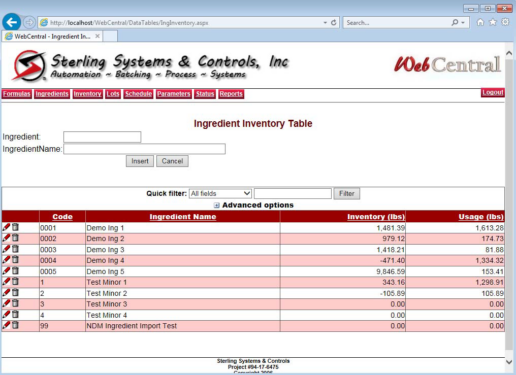

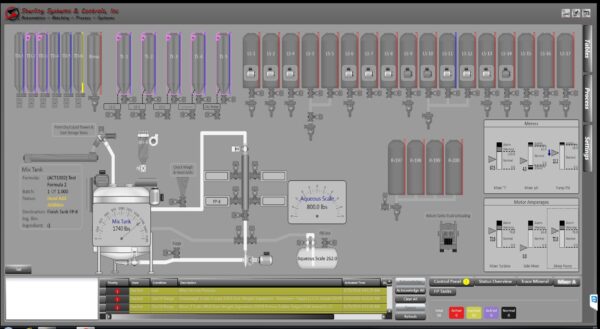

- HMI and operator interface design

- Automation software upgrades and system modernization

- Batch control and sequencing logic

- System integration and communication between platforms

- Control panel design and documentation

- Testing, commissioning, and validation support

- These services are commonly applied within batching systems, bulk material handling, and other automated process environments.

Automation Software Upgrades & Modernization

Many facilities operate control systems that have become obsolete, unsupported, or difficult to maintain. Sterling provides automation software upgrade services that help modernize existing control platforms while minimizing disruption to operations.

Software upgrades may involve updating control logic, migrating to supported platforms, improving system performance, or enhancing integration with newer equipment. Where possible, Sterling focuses on retaining existing hardware while addressing software limitations and long-term support risks.

Integration with Process & Material Handling Systems

Controls and automation systems often serve as the foundation for larger process solutions. Sterling integrates automation platforms with material handling equipment, batching systems, and process controls to ensure consistent operation across connected systems.

Controls and automation services are frequently paired with bulk bag handling systems, batching solutions, and other subsystem implementations to support reliable and coordinated process execution.

Design, Implementation & Lifecycle Support

Sterling supports controls and automation projects from initial system review through commissioning. Services may include system design, programming, testing, on-site start-up, and operator training.

By managing controls development and system integration under one scope, Sterling helps reduce risk during implementation and supports long-term system reliability as operational requirements evolve.

Frequently Asked Questions

What types of facilities use industrial controls and automation systems?

Controls and automation systems are used across food processing, chemical manufacturing, plastics, agriculture, mineral processing, and other industries that require reliable process control and coordination.

Can Sterling work with existing control platforms?

Yes. Sterling works with a wide range of existing PLCs, HMIs, and automation platforms and can integrate or modernize systems based on compatibility and application requirements.

When should an automation system be upgraded?

Upgrades are commonly considered when control platforms become obsolete, vendor support ends, performance issues increase, or integration with newer equipment is required.

Do controls and automation services support batching and material handling systems?

Yes. Controls and automation services are frequently applied to batching systems, bulk material handling, and other automated process environments.

Does Sterling provide commissioning and ongoing support?

Sterling provides commissioning support, operator training, and ongoing technical assistance to help maintain reliable control system operation.