Food & Baking Automation Systems

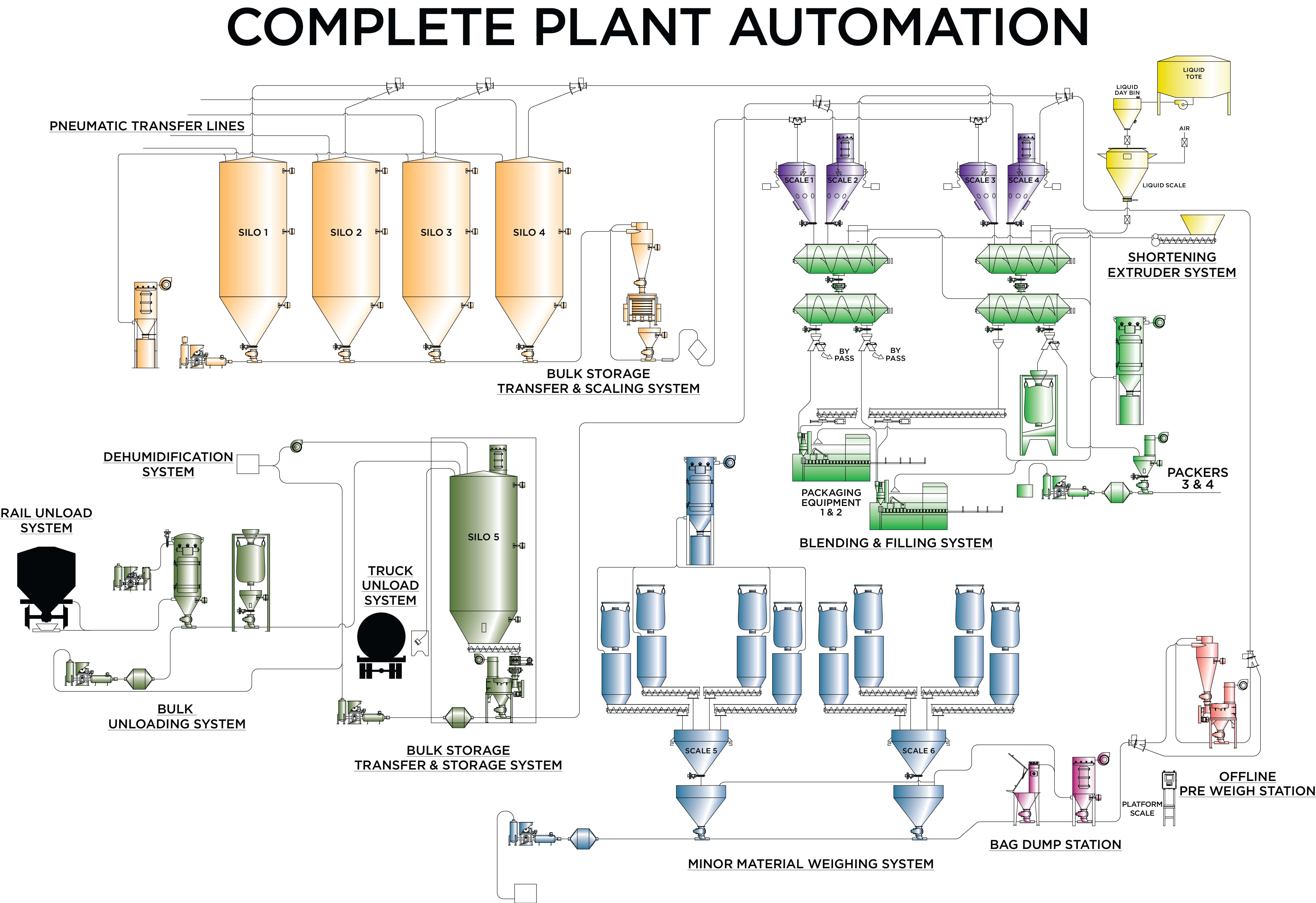

Sterling Systems & Controls designs and integrates food and baking automation systems that bring consistency, control, and traceability to commercial baking and food production operations. These systems coordinate ingredient handling, batching, mixing, processing, and packaging into a single, automated workflow supported by centralized controls.

Food and baking operations often involve complex formulations, precise ingredient ratios, and strict quality requirements. Sterling’s automation systems are engineered to manage these variables reliably—helping producers reduce manual handling, improve batch accuracy, and maintain repeatable product quality across production runs.

Sterling’s experience spans dry and liquid ingredient processes commonly found in baking and food manufacturing environments, including flour handling, sugar batching, fat and liquid additions, mixing, and downstream routing. Systems can be designed as standalone automation upgrades or as part of a complete plant automation solution, depending on operational needs.

What a Food & Baking Automation System Can Include

Sterling food and baking automation systems are configured based on application requirements and may integrate:

- Raw material receiving and storage automation

- Ingredient batching and weighing systems

- Dry and liquid ingredient handling

- Mixing and blending process control

- Recipe management and sequencing

- Automated transfer and routing between process steps

- Integration with ovens, proofers, or downstream packaging equipment

- Lot tracking, traceability, and production reporting

- Centralized operator interfaces and supervisory control

Each system is designed to function as a coordinated whole, allowing operators to manage production from a unified control platform rather than multiple disconnected systems.

System Design, Integration & Support

Sterling provides support throughout the full project lifecycle. This can include application review, system design, controls development, integration with existing equipment, on-site commissioning, and operator training. Where needed, Sterling can also assist with process validation and system optimization to ensure performance targets are met before full production.

By consolidating process automation, controls, and system integration under one provider, food and baking manufacturers can reduce integration risk and improve long-term system reliability.

How Do We Do It? It’s Easy!

Analyze

We interview your staff to determine the goals of your project.

Develop

With our application experience we develop a customized solution to meet your goals and make your process more efficient

Profit

You profit from our more than 50 years of experience in baking and food processing applications, process equipment, controls & automation, and data management.

Frequently Asked Questions

What types of food and baking operations use automation systems?

Food and baking automation systems are commonly used in commercial bakeries, snack food production, ingredient processing, and other food manufacturing operations that require precise batching, mixing, and process control.

How does automation improve consistency in baking applications?

Automation improves consistency by controlling ingredient weights, sequencing, and mixing parameters, reducing variation caused by manual handling and helping ensure repeatable product quality.

Can Sterling integrate automation with existing baking equipment?

Yes. Sterling can integrate new automation systems with existing mixers, handling equipment, ovens, and packaging lines, allowing facilities to upgrade without replacing all equipment.

Do these systems support recipe management and changeovers?

Yes. Food and baking automation systems can include recipe management tools that allow operators to select, modify, and execute formulations while controlling sequencing and batching accuracy.

Does Sterling provide training and ongoing support?

Sterling provides project management, system start-up assistance, operator training, and ongoing technical support to help facilities maintain reliable operation after installation.