Feed Mill Automation

Turn Over-the-Hopper into Turnkey Production

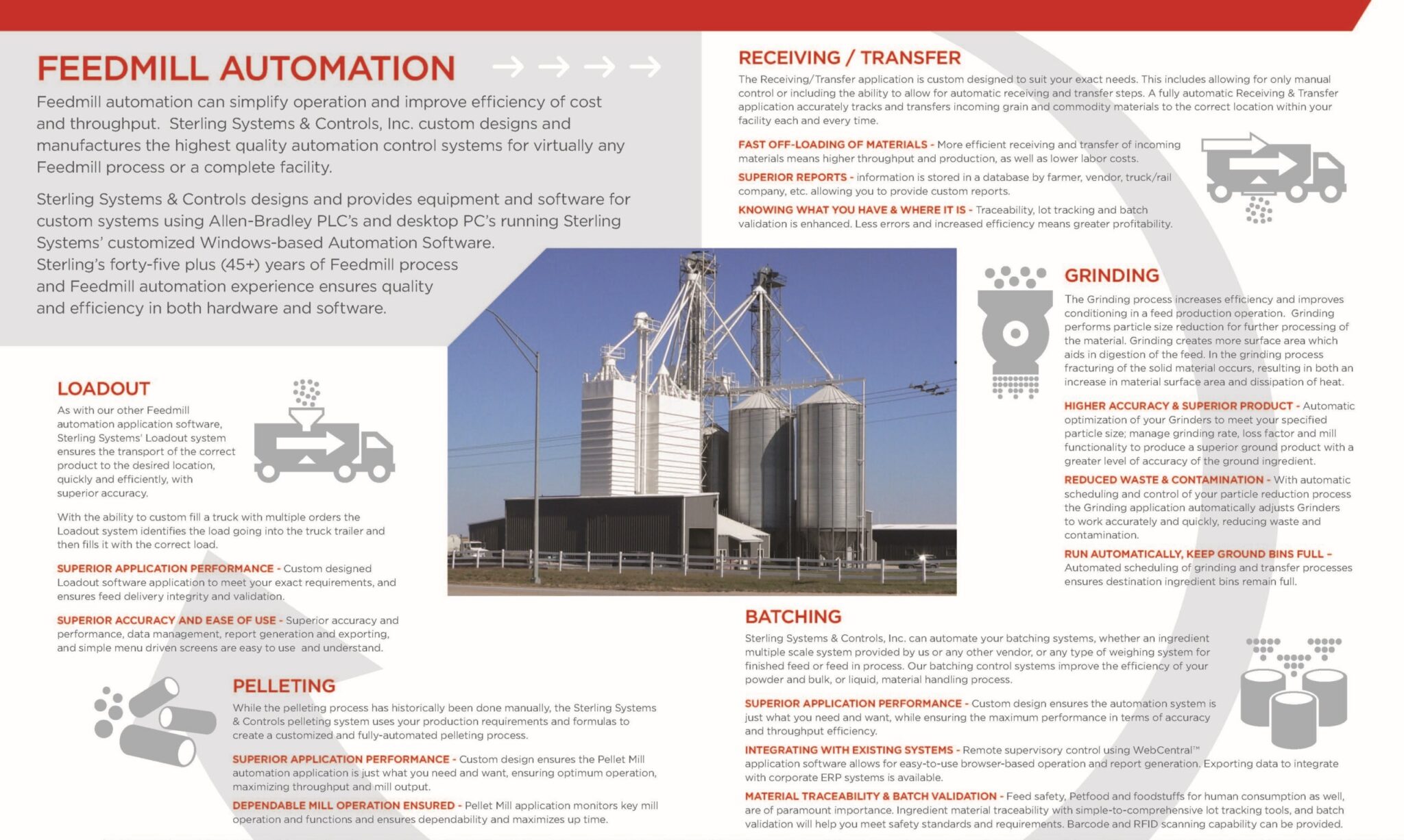

Feed mill automation can simplify operations, reduce cost and increase throughput for almost any feed-processing facility. Sterling Systems & Controls custom-engineers full feed-mill solutions (or subsystem upgrades) for cattle, poultry, swine, equine and specialty feed operations.

Why Automation Makes a Difference

- Manual or semi-manual mills face labor, error, and traceability risks.

- Automation links receiving, grinding, batching, pelleting, load-out and truck-scale systems under one control, improving safety, consistency and efficiency.

- Data capture: ingredient & vendor tracking, recipe/lot traceability, inventory management and remote access.

What Sterling Delivers

- Custom automation hardware & software built on Allen-Bradley PLCs, Windows-based PCs, and Sterling’s library.

- Modular process coverage: receiving/transfer, grinding, batching (micro/minor/major), pelleting, load-out/truck scale.

- SQL-based database and remote-supervisory WebCentral for real-time data and historic analysis.

Typical Automation Modules

- Receiving & Transfer: truck/rail scale, routing, inventory logging.

- Grinding Control: hammer/roller mills, schedule-driven, throughput monitoring.

- Batching & Mixing: recipe control, simultaneous scale use, database history.

- Load-out & Shipping: correct product/truck routing, sensor verification, automatic reporting.

Why Choose Sterling

- Over 50 years of automation experience in feed & related industries.

- Single-source integration of hardware, software, panels and system logic.

- Global support and long-term service commitment.

Ready to automate your entire feed-mill line or upgrade key subsystems? Contact us for an application review and we’ll map the automation architecture to optimize throughput, traceability and value.