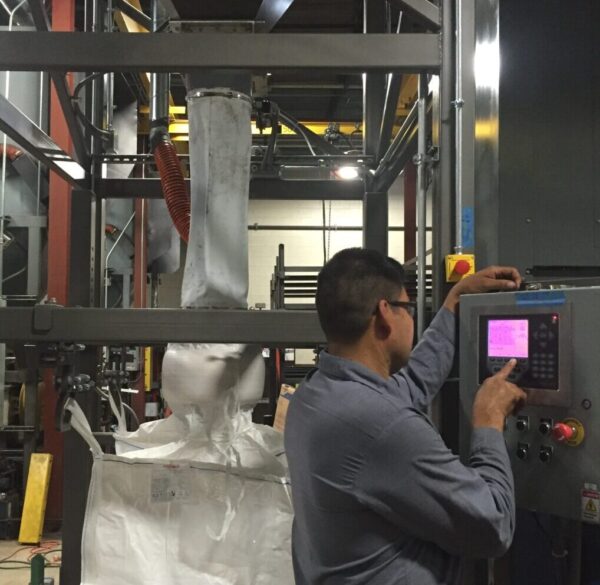

Bulk Bag Filling Systems

Sterling Systems & Controls, Inc. has designed and manufactured bulk bag loading systems for a wide range of applications. Whether as a standalone process or as part of an overall bulk material processing system, Sterling Systems & Controls bulk bag filling stations and packaging systems are custom-designed to fit your exact process requirements, and to perform the way you need and want them to. Sterling Systems & Controls will also design and provide the automation and process control system for the entire bag filling and packaging operation, which as an example, can include a Motor Starter Process Control Panel with an Allen-Bradley PLC (provides both discrete and analog outputs), an Allen-Bradley Panel View Plus color touchscreen, custom automation software including all M/O/A (Manual/Off/Automatic) switches with running indicating lights, motor starters, and all necessary fusing, wiring etc. to meet the application requirements.

Sterling Systems & Controls bulk bag filling systems incorporate many of the same structural aspects as the micro, minor, and major ingredient weighing systems, but are specifically designed to efficiently and effectively load/fill a bulk bag, usually at the end of the production process. Solutions are provided for filling bulk bags of dry bulk solid materials and filling supply bins such as drums or tote tippers. Bulk bag packaging systems can be combined with a variety of turnkey solutions for batching, mixing, conveying/transporting, etc.. Many options can be provided, including an accumulating conveyor, etc.. Sterling Systems & Controls designs the bulk bag systems within the physical constraints of your facility and can provide the controls required as a standalone process or as a part of the complete manufacturing process automation.