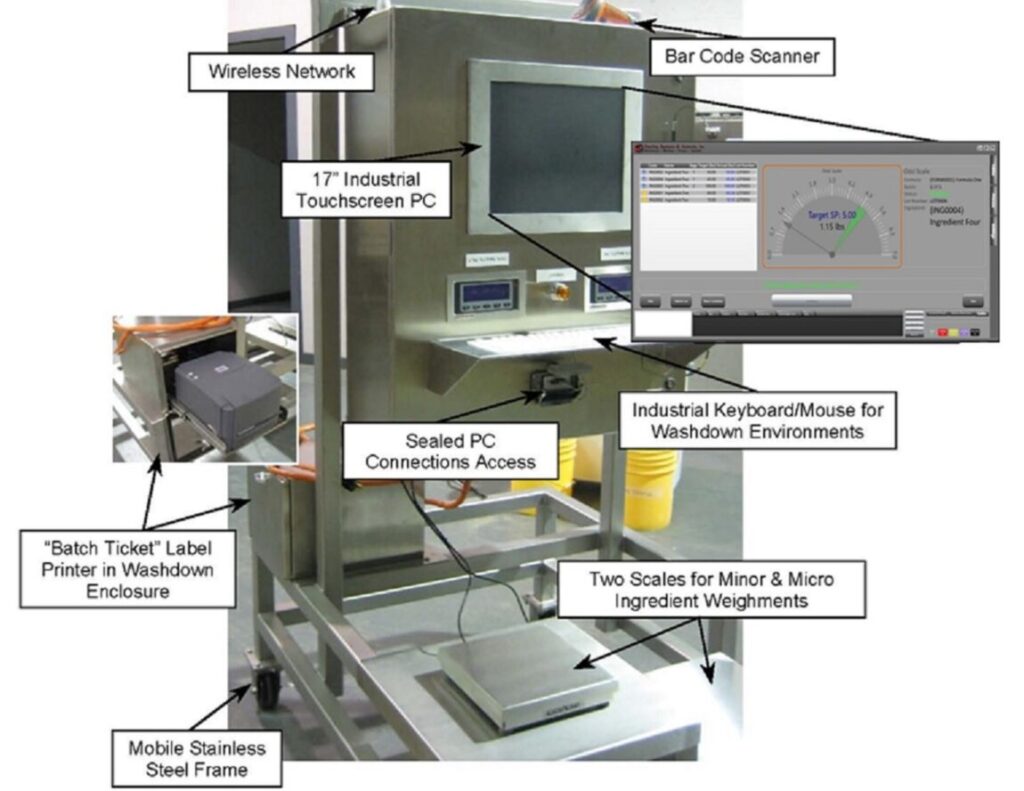

Hand Prompt Batching Station

Stop relying on error-prone manual batching. The Hand Prompt Batching Station from Sterling Systems & Controls blends operator involvement with automated guidance to deliver higher accuracy, better lot-traceability, and scalable growth. Designed for minor and micro-ingredient batching in food, pet-food, feed and industrial markets, the system lets you maintain your current workflow while eliminating missed ingredients and bad batches.

Key Features & Benefits:

Real-Time Reporting: Batch data, date/time stamps, ingredient details and weights are captured and optionally printed or network-accessed—enabling production oversight and continuous improvement.

Operator-Prompted Workflow: The system sequences operators through each ingredient step-by-step, replacing printed recipes and reducing reliance on memory or manual checklists.

Weighing & Validation Built-In: Each ingredient must be weighed within programmed tolerances before the next step—so bad batches caused by omissions or interruptions become a thing of the past.

Lot Tracking & Database-Driven: Powered by an industry-standard SQL database, every ingredient lot and batch is stored for full traceability and audit readiness.

Scalable Investment: Start with a semi-automatic station now and upgrade later to a full automatic micro/minor/major batching system — your software and data infrastructure grow with you.

Seamless Process Fit: Unlike rigid manual systems, this station adapts to your existing process rather than forcing you to change it. Minimal disruption, maximum improvement.

How It Works:

- Operator selects a formula and number of batches.

- The system prompts to place the container on the scale and then instructs ingredient addition one at a time.

- If lot-tracking is enabled, the operator enters or scans the lot number before weighing.

- Full-bag weighments and “odd weights” are handled automatically based on your configuration.

- After the final ingredient, the system prompts container removal and prints or stores the batch report.

- Alarm or override features enable supervision in case of exceptions.

- Database backups and maintenance are fully automated, keeping your system robust.

Applications & Industries:

Ideal for: food & baking, pet food & feed, nutraceuticals, chemical powders, compounding. Wherever ingredient precision, traceability, and operator-assisted batching matter.

Why Choose Sterling’s Hand-Prompt Station:

- Lower initial investment than full automatic systems—yet you gain key features of automation, traceability and operator assistance.

- Custom-engineered solutions built on 50+ years of process control expertise.

- Global support and integration, including plant-network connectivity, remote data access and upgrade paths.

Ready to eliminate bad batches, streamline your ingredient workflow, and capture full batch data? Request a quote below or speak with our application engineers to see how the Hand Prompt Batching Station can integrate into your current process.