Batching Systems

From Formula to Finished Batch, Controlled & Traceable

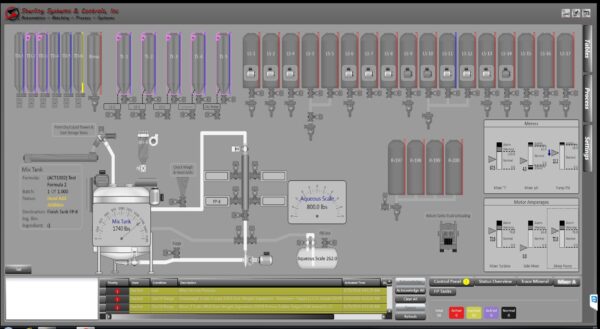

Sterling’s ingredient batching systems—both automatic and semi-automatic—are custom-engineered to boost throughput, enforce accuracy, and provide full production traceability. Whether you’re working with powders, bulk materials, or liquids, our systems deliver repeatable performance, eliminate waste, and integrate with your data infrastructure.

What Sets Our Batching Systems Apart

Third-party friendly hardware: Systems built on non-proprietary platforms (Windows, SQL Server, Rockwell FactoryTalk View, .NET) ensure longevity and supportability.

Ingredient control from micro to major: Modular systems support 1 to 8 scales and up to 48 supply bins, sized based on ingredient weight, batch rate and storage needs.

Semi-automatic or full automatic: From hand-prompted additions to fully programmed sequences, the same foundation of PLC/HMI, SQL database and recipe logic applies.

Data & traceability built-in: Every batch step is logged—material lot, weight, date/time, operator—and reports are available for audits, continuous improvement and ERP/MES integration.

Flexible, modular architecture: Start with your most critical ingredients, then expand. Use auger feeders (2”–6”), vibratory feeders, or rotary airlocks for bulk inputs.

Custom Semi-Automatic Batch Weighing Systems

In addition to fully automatic batching systems, Sterling Systems & Controls can provide customized semi-automatic (hand add/hand prompt) batch weighing systems. These can also be provided as Kitchen Batching Systems. Semi-automatic systems can also be incorporated together with an automatic batching system to provide a hybrid batching system. Semi-automatic systems are based on the same automation technology as automatic systems, with the same capabilities that ensure a hand-add process is monitored, processed, controlled, and documented for optimal performance and reliability. This creates a validation system for the semi-automatic batching process. All semi-automatic systems include tolerance control and lot tracking/validation to eliminate missed ingredients due to operator interruption, ensuring that all of the correct materials are being weighed to the specification of the programmable formula.

- Batching of dry & liquid, micro/minor/major ingredients, hand-add or full automation

- Inventory monitoring for unlimited raw materials

- Tolerance control for accurate weights and batch integrity

- Barcode or RFID lot verification and batch validation

- Multiple user security levels and password-protected operations

- Integration with mixers, conveyors (pneumatic/mechanical), packaging, bulk handling

- NEMA/food-grade enclosures and full documentation for compliance

Industries & Applications

Food processing, baking, pet food, animal feed, rubber and compounding, chemicals, plastics—any process where consistent formulation, traceability and production data are required.

Ready to engineer your next batch system? Let’s review your formulas, ingredient flow, and data goals—then build a solution that delivers accuracy, throughput and traceability from the start.

Frequently Asked Questions

What is an ingredient batching system?

An ingredient batching system is an automated or semi-automatic controls and weighing solution that measures, sequences, and validates ingredients according to a programmable formula to produce consistent batches with traceability.

What is the difference between automatic and semi-automatic batching?

Automatic batching executes programmed sequences for ingredient delivery and weighing, while semi-automatic batching uses hand-add or hand-prompt steps with the same controls logic, tolerances, and documentation to validate the process.

How do batching systems support traceability and audits?

Batching systems can log each batch step, including ingredient identity, lot information, actual weights, timestamps, and operator actions, and generate reports for audits and continuous improvement.

Can batching systems handle micro, minor, and major ingredients in one platform?

Yes. Modular batching architectures can support multiple scales and bins so a facility can manage micro through major ingredients within a unified batching and data framework.

Can Sterling batching systems integrate with mixers, conveying, packaging, and data systems?

Yes. Batching systems can be integrated with downstream equipment such as mixers and conveying/packaging systems, and can support data connectivity for production reporting and ERP/MES-aligned workflows.