Preventative Maintenence

Build Your Plant

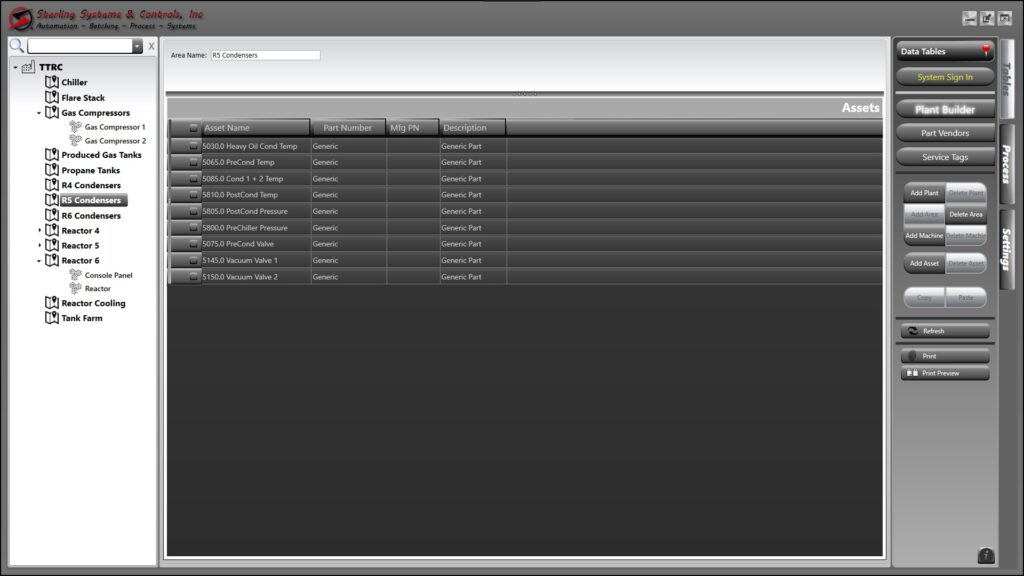

PMPlanR™ (pronounced “PM-Planer”) is a robust standalone Preventative Maintenance Planning Software Application from Sterling Systems & Controls, Inc.. PMPlanR allows you to “Build Your Plant”. Within each Plant you can enter all Equipment Components (Areas or Machines) and Assets that should be monitored.

Each Plant that is set up can be divided into Areas and Machines. A Plant, Area and Machine are all “Categories”. A Plant Category can have multiple Area Categories that pertain to a specific process or production area. Within each Area Category are Machine Categories that build a production process. Assets are categorized under Plants, Areas and/or Machines. Plant, Area and Machine categories are used to help organize Assets, each Asset being able to be defined with a name and vendor part number.

PMPlanR preventative maintenance planning software can be installed on any Windows 7 or 10 operating system. Accessing or signing into the PMPlanR software requires you to have a username and password, all set up in the Security Manager section of the software. The three primary areas of interest for users of the PMPlanR software are Plant Builder, Part Vendor, Service Tags, Preventative Maintenance & Work Orders and History Reports. Other sections include System Parameters, Security Manager and PLC Communications.