Rubber Batching

The first step in most rubber manufacturing processes is compounding. This requires the accurate batching of ingredients together for further processing. Most often, to produce a rubber compound a combination of plastic resin (pellets, flakes, powders, or liquid) is combined with other materials, including liquids and/or bulk solid materials. Sterling Systems & Controls, Inc. designed and supplied a customized batching system for a rubber compounding application where industrial hoses and fittings are manufactured. This rubber batching system includes a minor ingredient batching system, a hand-add semi-automatic batching system, dust collection, automatic indexing of totes (also provided by Sterling Systems & Controls) and a state-of-the-art automation control system including standard Allen-Bradley PanelView+ touchscreen HMI’s and PLC, and a Sterling Systems & Controls customized FactoryTalk ME software application. Electrical controls are also provided.

Rubber Batching Example

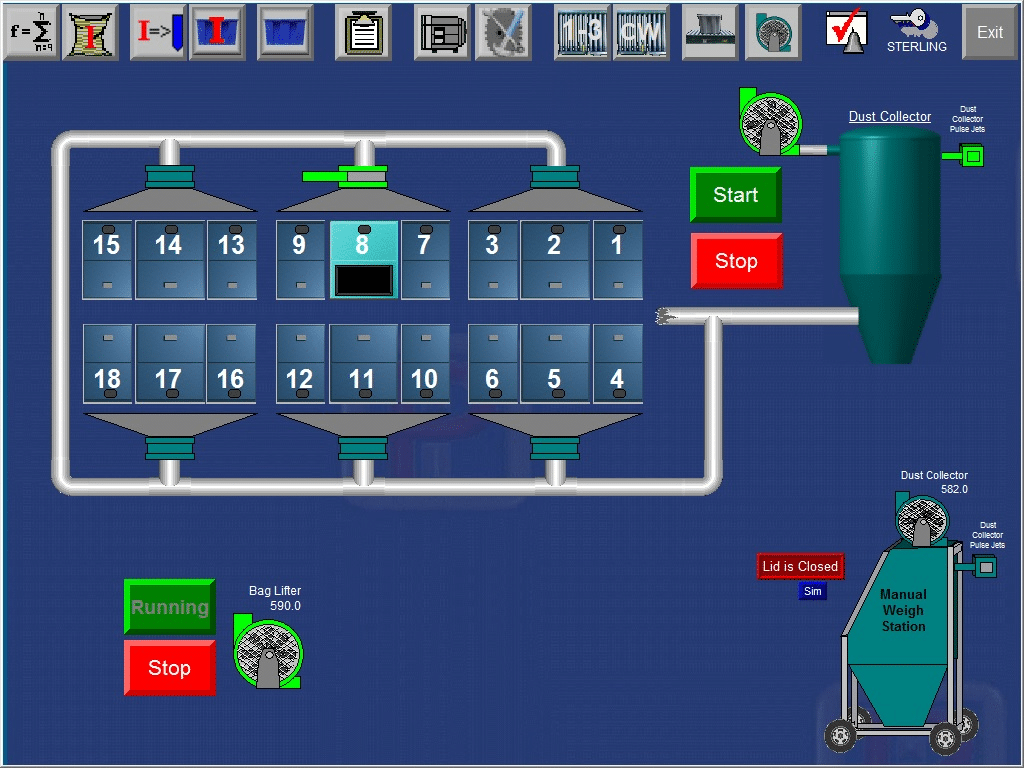

In this application example, the automated rubber batching minor ingredient system supplied by Sterling Systems & Controls consists of eighteen (18) coated mild steel storage bins and augers, an industrial TEFC electric motor for each feeder, 18 bin vibrators, coated mild steel tubular frames supporting bins and a conveyor system (infeed conveyor, scale 1 conveyor, scale 2 conveyor, scale 3 conveyor, checkweigh scale conveyor, exit conveyor, and return conveyor), stairway, stairway landing stand, and a double pallet stand. Also included are two scissor lifts and a pneumatic bag hoist.

The rubber batching system also includes four (4) control panels: an Automatic System Operator Control Panel, a Hand-Add Weigh Station Panel, a Scale Indicator Panel, and a PLC/Starter panel. Four (4) air solenoid racks/manifolds with distributed I/O are also included. All panels are rated NEMA12 and of coated mild steel construction. All VFDs, contactors, and PLC processors are Allen-Bradley. Four weight instruments are installed and preconfigured for EtherNet/IP communications on the Scale Panel and there is one weight instrument on the Hand-Add Weigh Station Panel.

This rubber batching system is also provided with a customized dust collection system to control airborne dust during the batching operation. Shown here is the installed rubber batching system with dust control takeoff affixed above indexing totes under each ingredient bin, and also dust hoods and ducting from above the ingredient bins in the rubber batching system.

The controlling software is a Sterling Systems & Controls customized Rockwell Software FactoryTalk View ME running on PanelView+ Touchscreen HMIs in the operator control panels where formulas and ingredients are created, and scheduled to batch. Up to 25 formulas containing up to 75 ingredients each can be stored simultaneously in the PLC of this rubber batching system. Sterling Systems & Controls also included the WebCentral supervisory control application software to provide remote access to data and reports. This rubber batching system produced accurate ingredient weighments to within +/- 0.05lbs for 0.5lb weighments, and +/- 0.1lbs for 1.0lb weighments. Each process control and/or batching system is customized to meet the exact requirements of each specific customer. Typically, no two systems are the same.

WebCentral™ Supervisory Control

Added to this rubber batching system is Sterling Systems & Controls WebCentral supervisory control application. WebCentral is a browser-based software package allowing corporate network users to access data from the Sterling Systems & Controls, Inc. batching control system. WebCentral provides the ability to manage Ingredients, Formulas, Bin Assignments, Schedules, and other data tables as well as view and print historical batching and process data reports. PLC-based control systems are generally constrained by limited PLC memory and can only hold a limited amount of data (Ingredients, Formulas, etc) at one time. However, since WebCentral stores data in a Microsoft SQL Server (or SQL Express) database, a nearly unlimited amount of data can be stored and maintained. WebCentral provides a convenient way to choose a subset of data from the database and download it to the batching control system for use, thus overcoming the limited nature of the PLC storage capacity. Data that is entered or modified on the plant floor through the batching control system can also be uploaded using WebCentral to provide a means of backup and storage of the data that is in the PLC. WebCentral also monitors key process and batching data and alarm conditions within the control system and provides logging and historical analysis of this data. In short, PLC’s and Control Systems are good at controlling equipment, whereas Computers and Databases are good at managing data, and WebCentral uniquely provides the means to bridge these two worlds to provide a seamlessly integrated rubber batching solution.