Automating Bulk Solids Processes

The storage, handling, and processing of bulk solids will almost always provide an opportunity to automate bulk solids processes. No matter what the industry, there may be several machines and/or processes that need to be controlled and automated to ensure quality and productivity. Bulk solids processes that can require automating include:

- Batching

- Mixing/Blending

- Grinding/Sizing/Classifying

- Pelleting

- Screening

- Bulk Bad Unloading

- Bag Filling

- Raw Material Receiving

- Material Transfer w/Production Process

- Finish Product Loadout

- Truck/Rail Car Weighing

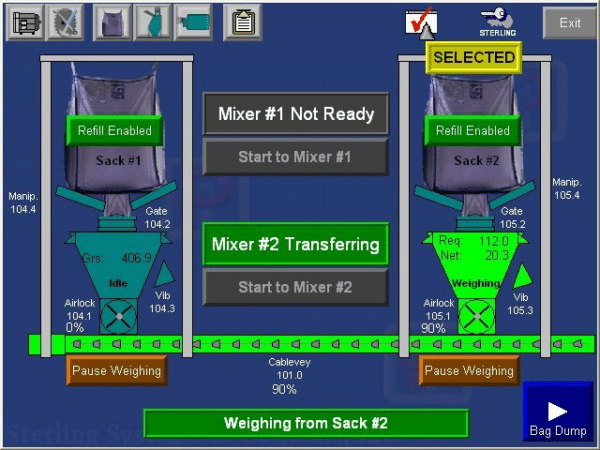

In this food industry application example, a customer needed to control two bulk bag unloaders, a bag dump and also a mixing process. Sterling Systems & Controls, Inc. was selected to perform the automating of these bulk solids processes due to Sterling Systems & Controls vast process knowledge, more than 50 years in designing and manufacturing custom process control and automation systems using standard components, a unique WebCentral remote supervisory control application, and more.

Sequence of Operation – Automating Bulk Solids Processes

The control system consists of two stainless steel control panels. The “Main Control Panel” contains an E-Stop, Alarm Horn and Beacon, Alarm Silence button, Bulk Bag Selector Switch, and a 10” PanelView Plus 1000 Color Touchscreen HMI. The Scale Control Panel contains the weigh indicators for each bulk bag unloader. The system is integrated with external “Mixer Ready” and “Transfer Complete” signals for the coordination of transferring ingredients to two different mixers. Programming for integrating the controls with the existing Mixer systems is also implemented by Sterling Systems & Controls, Inc. The system operates as follows:

- The operator selects a formula from the existing mixer system containing a setpoint value for “Ingredient #1” on the Mixer PanelView.

- The mixer system passes the Ingredient #1 setpoint to the Sterling Systems & Controls bulk solids processing system, indicating it is ready.

- The operator pre-stages the ingredients in the Bag Dump Station.

- The operator presses “Start” on the PanelView on the Main Control Panel.

- Ingredient #1 (if needed) is pulled from the selected bulk bag.

- Simultaneously, the bag dump discharges.

- When both the bulk bag and bag dump are done, the system purges the conveyor.

- The Sterling Systems & Controls processing system passes the actual amount of Ingredient #1 delivered to the mixer system and indicates the operation is completed.

Bulk Bag (FIBC bag or Tote) Process

The equipment is operated in the following manner:

- The operator ensures that the control panel E-Stop is pulled out and the system is powered up and ready. The operator places all equipment in the Automatic Mode using the Touchscreen HMI.

- The system waits for a “Mixer Ready” signal.

- When the Mixer Ready signal is received, the system displays an indication on the screen that the mixer is ready to receive ingredients and the mixer Start button is displayed on the screen. In this specific application, there are two mixers, and each mixer has a separate start button, allowing the operator to select which mixer will be used if more than one mixer is ready at the same time. The system will interlock the “Ready” signals such that if Mixer #1 Ready signal is received before Mixer #2 Ready, the system requires the operator to press the start button for Mixer #1 before Mixer #2. A password-protected system parameter is available to override this interlock if required.

- If a mixer is ready and the system has not yet been started before a user-programmable “Mixer Waiting Alarm Delay” timer has expired, then the system raises an alarm to gain the attention of the operator to prevent time being wasted. The alarm can be disabled through the system parameters screen if desired.

- The operator chooses which bulk bag unit to use by flipping the Bag #1 / Bag #2 switch on the front of the Main Control Panel. The system examines the state of this switch at the beginning of each weighment. Flipping the switch while the system is weighing will have no effect.

- If the operator has chosen a formula on the existing Mixer System with a value in the setpoint for Ingredient #1, the system obtains the setpoint for Ingredient #1 from the Mixer System.

- When the operator presses the start button, if the setpoint for Ingredient #1 obtained from the Mixer System is greater than zero, then the System begins discharging Ingredient #1 from the selected bulk bag.

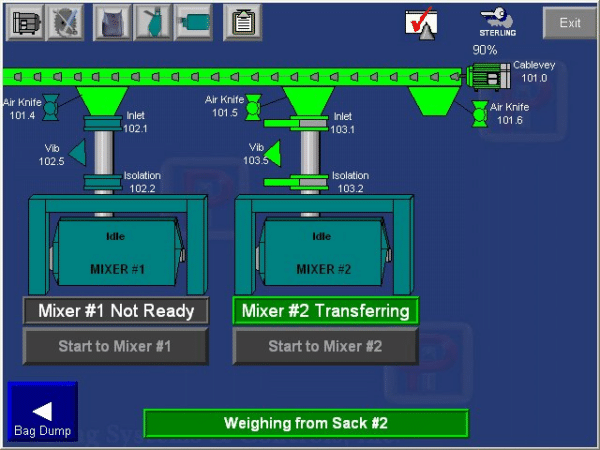

- The system opens the appropriate Mixer Isolation Valve and confirms that it is open.

- The system opens the appropriate Mixer Inlet Valve and confirms that it is open.

- The system activates the appropriate Conveyor Air Knife Valve based on which Mixer Inlet Valve is open.

- The system starts the Conveyor at a user-programmable speed and confirms that it is running. The Mixer has a separate speed setpoint on the HMI, which is security-protected and user-adjustable.

- The system continuously monitors the Conveyor Cable Tension Switch and raises an alarm if there is a problem with the conveyor.

- The system obtains a Tare Weight of the selected Bulk Bag Scale.

- The appropriate Airlock is started at a user-programmable Fast Speed.

- The system monitors the Net Weight in the Super Sack Scale and begins discharging Ingredient #1 in a Loss-In-Weight fashion. When the Net Weight of the scale passes the user-programmable “Fast Cutoff” setpoint, then the System reduces the speed of the airlock to finish the weighment at a user-programmable slow speed.

- Once the Net Weight of the bulk bag scale passes the user-programmable “Slow Cutoff” setpoint, the airlock is stopped, and the scale will be allowed to settle.

- The system will evaluate the final net weight obtained by comparing it to a user-programmable set of over and under-tolerances.

- If the net weight is below the under tolerance, and a programmable jog time has been specified, the system will jog the airlock for a short time to bring the net weight within tolerance. If the jog time has been set to zero, the system raises an underweight alarm that needs to be acknowledged by the operator before the system will be allowed to continue.

- If the net weight is above the over tolerance, then an overweight alarm is raised and must be accepted by the operator before the system will be allowed to continue.

- Once the weighment has been completed, the actual weight is passed back to the Mixer System and the system continues with the bag dump process.

Bag Dump Process

The equipment is operated in the following manner during the bulk bag scale refill process:

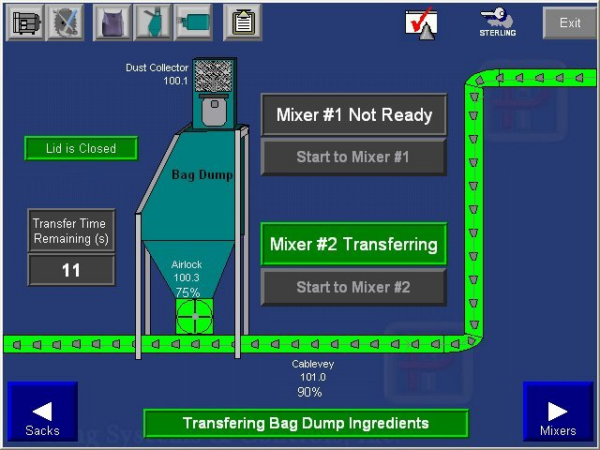

The bag dump process occurs simultaneously with the bulk bag process. The equipment operates in the following manner during the bag dump process:

- The system starts the bag dump airlock at a user-programmable speed and confirms that it is running. The appropriate mixer has a separate speed setpoint on the HMI that is security-protected and user-adjustable.

- The system starts a user-programmable “Bag Dump Transfer Timer”.

- Upon expiration of the transfer timer the system immediately stops the bag dump airlock. An “End Transfer Timer” button is provided that allows the operator to end the transfer process early if the bag dump is empty before the timer expires.

- Upon expiration of the bag dump transfer timer and completion of the bulk bag weighing, the system starts a user-programmable Purge Timer for the conveyor.

- When the purge timer expires, the system stops the conveyor and closes the Mixer Inlet and Isolation Valves, and turns off the Conveyor Air Knives.

- The system turns on a “Mixer Complete” signal to indicate to the external Mixer Control System that the process has been completed. The Mixer Complete signal remains on until the “Mixer Ready” signal coming from the mixer is turned off by the mixer control system.

- The system returns to an Idle state and returns to bulk bag process step #1 above in preparation for the next transfer.

Bag Dump Dust Collector

The Bag Dump Dust Collector will be operated in the following manner:

- The Bag Dump Dust Collector and Pulse Jet Timer Board operate any time the system detects that the bag dump lid is open.

- When the bag dump lid is closed a programmable delay timer will be started.

- Upon expiration of the delay timer the bag dump dust collector and pulse jet timer board will be stopped.

Alarms

The System continuously monitors equipment and generates Alarm Messages on the HMI for abnormal equipment conditions, which also are annunciated through the Alarm Horn and Beacon on the control panel. Equipment Alarm conditions include:

- “Mixer Inlet Valves Not Open” or “Mixer Inlet Valves Not Closed”:

- Conveyor will not be allowed to start or will be shut down if it is currently running

- “Conveyor VFD Fault”:

- Bag Dump Airlock or Bulk Bag will not start or is shut down immediately if it is currently running.

- Faults are manually cleared/reset from the HMI without opening the control panel door.

- “Conveyor Cable Tension Fault”:

- Bag Dump Airlock or Bag Dump will not start or will be shut down immediately if it is currently running.

- Conveyor will not be allowed to start or will be shut down immediately if it is currently running.

- “Bag Dump Airlock VFD Fault”:

- The conveyor will continue to run

- Faults are manually cleared/reset from the HMI without opening the control panel door.

- “Bag Dump Dust Collector Motor Fault”

- All other equipment will continue to operate.

- Faults are manually cleared/reset from the HMI without opening the Control Panel door.

- “Bag Dump Lid Not Closed”:

- Equipment does not start if the bag dump lid is open.

- If equipment is running and the lid is opened, the bag dump airlock will be stopped immediately.

- “Bulk Bag Airlock VFD Fault”:

- The conveyor will continue to run.

- Faults are manually cleared/reset from the HMI without opening the control panel door.

- “Bulk Bag Scale Inlet Gate Not Open” or “Bulk Bag Scale Inlet Valve Not Closed”:

- Weighing does not start when the scale is refilling or if the gate valve is not closed.

- “Bulk Bag Scale Indicator Failure”:

- Equipment is not allowed to start. If the bulk bag airlock is running, it will be stopped immediately.

- “Not Enough Weight In Scale to Start”:

- This Alarm indicates there is not enough weight on the bulk bag scale to satisfy the requested setpoint. Equipment is not started

until a new bag is loaded and the scale has been refilled.

- This Alarm indicates there is not enough weight on the bulk bag scale to satisfy the requested setpoint. Equipment is not started

- “Bulk Bag Scale Not Refilling”:

- If the bulk bag scale is attempting to refill and the scale has reached the Full Weight after a user-programmable time period, this alarm will be raised to alert the operator to change the bag or correct a product flow problem.

Manual Control

All equipment can be individually controlled manually from the touchscreen HMI by setting the equipment to either Manual, Off, or Automatic mode. When a piece of equipment is put in manual mode it will be started immediately with no interlocks and will continue to run until it is taken out of manual mode. When placed in off mode the equipment will be turned off immediately. Off mode should NOT be used as a substitute for proper lockout/tagout procedures. When in automatic mode equipment will be started and stopped automatically and interlocked with other equipment and sensor conditions. In general, all equipment should be placed in automatic mode at all times except when maintenance procedures or extenuating circumstances dictate otherwise. When in manual mode, the conveyor can also be reversed to change the direction of the conveyor during cleaning.

Mixer Control System Integration

- Sterling Systems & Controls, Inc. revised the existing mixer control system PLC code to implement the exchange of information between the Sterling system and the mixer control system.

- A new “Ingredient #1” setpoint is added to all formulas and appropriate screens on the Mixer PanelViews. When a value is present in this field, it will be sent to the Sterling Systems & Controls system as the setpoint for the selected bulk bag. The existing setpoint for another ingredient is relabeled “Liquid Ingredient” and will continue to be sent to the liquid system. It is the responsibility of the operator or supervisor to ensure the appropriate value has been entered into either the “Ingredient #1” or “Liquid Ingredient” setpoint fields.

- In addition to obtaining the setpoint for Ingredient #1 from the mixer system, the actual weight of Ingredient #1 will be sent from the Sterling system back to the mixer system for display on the existing batching screen in the “Ingredient #1 Actual” field.

- All integration is done using EtherNet/IP on the facility’ existing control network. As such, the customer provides four static IP Addresses for the new Sterling Systems & Controls equipment to be resident on the existing facility network. IP Addresses exist for the following Sterling Systems & Controls provided equipment:

- CompactLogix L32E PLC Processor

- PanelView Plus 1000

- Weight Indicator for Bulk Bag #1

- Weight Indicator for Bulk Bag #2