Hand Prompt Batching

Sterling Systems & Controls batch control system includes a semi-automatic system called the Hand Prompt Batching Station. It may also be called a Hand Prompt Batching System or Batching Controller. Some may also refer to it as a Manual System as the addition of each ingredient is fed manually by an operator into the batch container, though to call this system “manual” is a misnomer. Other than material feeding, the system automatically weighs and controls operator actions and provides lot tracking and batch validation capabilities.

The semi-automatic Hand Prompt Batching Station can be implemented or applied in many different industries ranging from Pet Food to Feed Production, to Baking and Food Processing, and much more. It is a batching system at the low end of the cost scale when compared to fully automatic batching and weighing systems.

Hand Prompt Batching – Receiving Process

Raw ingredients for your formulas/recipes are received, the following procedure is used:

- The operator logs into WebCentral (assuming the overall system is so equipped) using a browser that is on a PC that is located in his area, perhaps it is the receiving area and on the same network as the Hand Prompt Batching System. Optionally, the operator may use the Hand Prompt Batching System operator interface instead.

- The operator chooses the “Add New Lot” option on the “lot table” screen.

- The operator enters a new unique lot number.

- The operator picks the ingredient from a list of previously entered ingredients. If this is a new ingredient, the operator or supervisor first adds the ingredient to the ingredient table.

- The operator enters the amount of ingredient being received.

- The operator can optionally print a lot of labels if required. Information on the label will include Ingredient Code, Ingredient Name, Lot Number, Lot Number Bar Code, and Vendor Number.

- The operator can optionally print a lot of bag labels if required. The lot bag label includes several barcodes containing the lot number and a bag number that is intended to be attached to individual bags of the ingredient.

Hand Prompt Batching – Batching Process

- The following describes a typical operational process of the Hand Prompt Batching Station system. It is assumed that all ingredient and formulation data have already been entered into the system and that the Receiving Process has been followed to generate the appropriate lot numbers for the raw ingredients. It is also assumed that the system is idle and powered up and ready for batching.

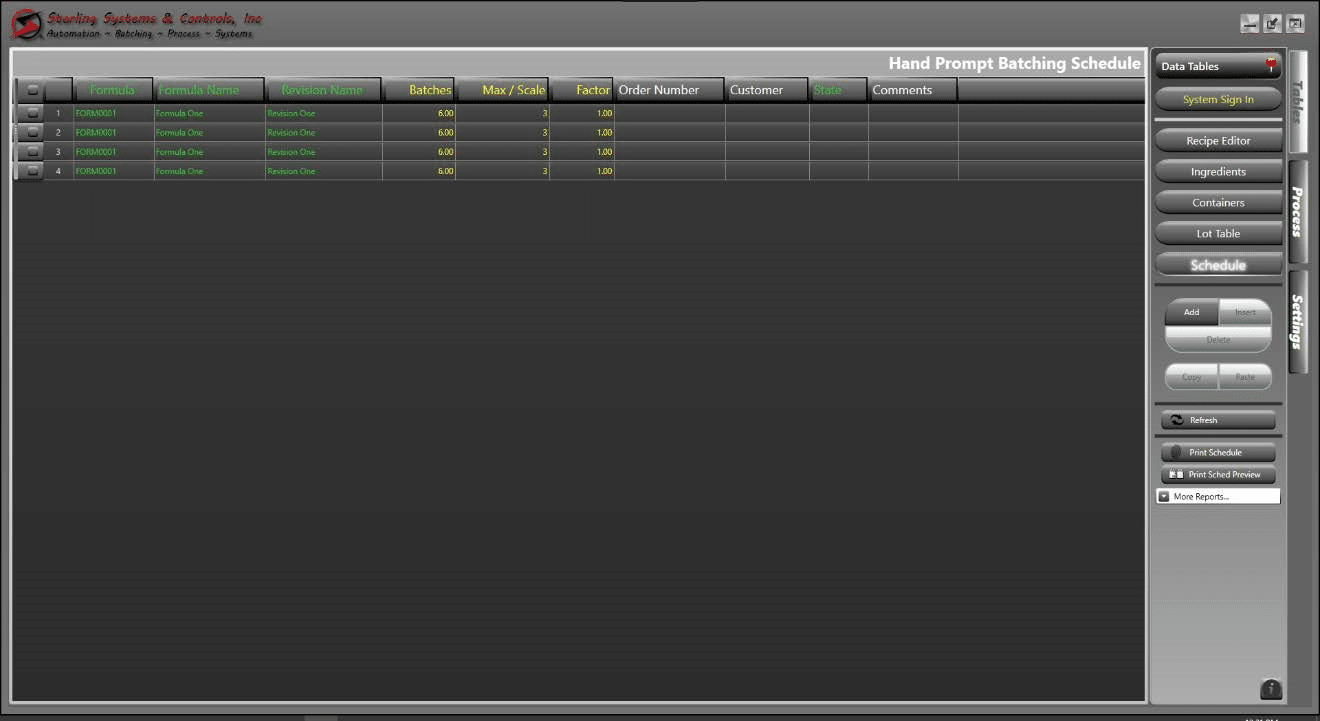

- The Batching Schedule is entered either remotely through the WebCentral software or directly at the Hand Prompt Batching Station. Scheduling involves 1) picking which formula to run, 2) specifying the number of batches to run at a time, and 3) specifying the total number of batches to run.

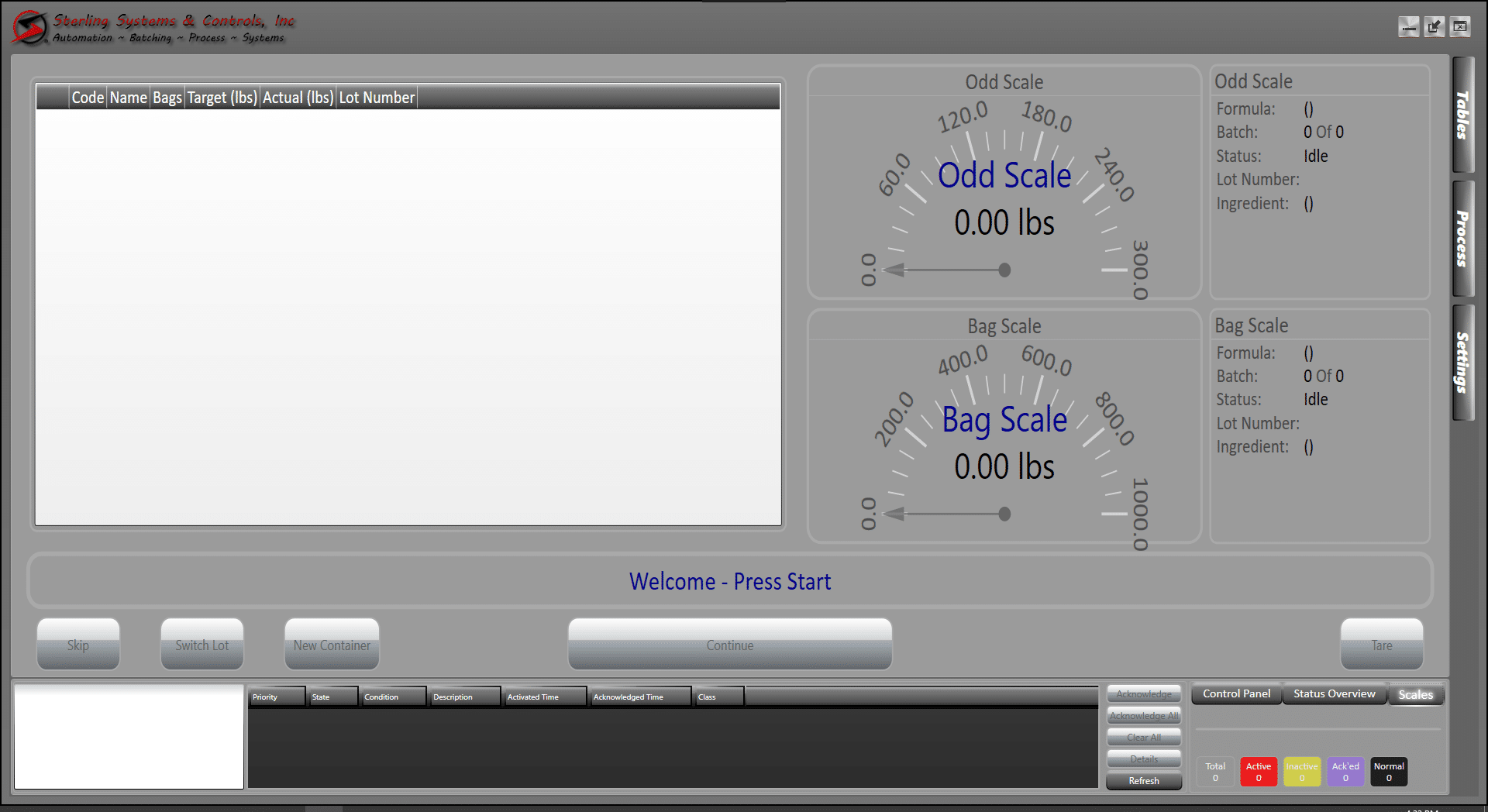

- The Operator will go to the main graphical batching screen and press the Start button on the screen. If any problems occur or the system encounters anything unexpected in the formula, the operator may be required to review the formula before the batch can be started.

- The system will determine which scale(s) to use for each ingredient based on the formula. Different scales can be used for bag weights, odd weights, or specifically overridden for individual weighments.

- The system will prompt the operator to place an empty batch container on the appropriate scale, scanning it first if batch container tracking is being used, and pressing the “Continue” button when ready. The system will then capture a tare weight for the scale.

- If lot tracking is being used, the system will prompt the operator to enter an ingredient lot number before continuing.

- The system will then display the name and code of the first programmed ingredient in the formula.

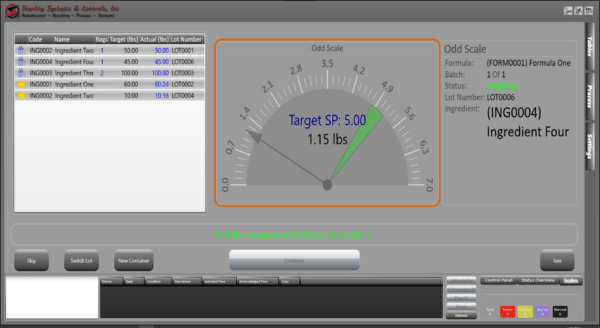

- If a “Bag Size” has been programmed for the selected ingredient, the system will automatically calculate the number of whole bags required and also any additional “Odd Weight” that will be required. For example, if an ingredient comes in 50lbs bags and the formula requires 55lbs, the system will prompt for 1 full bag and later will ask the operator to weigh the additional 5lb “Odd Weight” on a scale. Bags may optionally be weighed on a scale, in which case the system will require the bags to be in place on the appropriate scale to continue, and later will adjust the odd weight to compensate for discrepancies in bag weights. Otherwise, the operator simply acknowledges that the bags have been picked and continues. The operator may also choose to ‘skip’ the ingredient, which allows them to weigh or acknowledge the following ingredients first in case of delays in retrieving a certain ingredient. The system will return to the skipped ingredient after the others are completed.

- The system will prompt the operator to weigh the “Odd Weight” on the configured scale. If the Bag Size parameter has been set to zero, the “Odd Weight” will be the full target amount specified in the formula, otherwise, it will be the remainder that is required after prompting for full bags first, possibly adjusted if the bags were weighed. If it is desirable to complete all full bag weights together, the odd weights can optionally be delayed until all the bags have been picked and acknowledged. If the container becomes full before the weighment has been completed, the system will indicate an alarm for the operator who can choose to finish weighing or replace the container. The system will continue weighing where it left off after the container has been replaced.

- Once the net weight of the scale is within the programmed tolerance for the ingredient, the system will allow the operator to continue.

- The system will advance to the next Ingredient, returning to fourth step in the batching process (shown above) for each ingredient programmed in the formula. If another container is required on the scale for another batch, the system will return to step #3 above.

- Once all of the ingredients have been weighed or acknowledged, the system will prompt the operator to remove all containers from the scale(s).

- Once the containers are removed, the system can print a batch container label for each container if enabled. Information on the label will include the start and end date/time for the batch, the formula code and name, and each ingredient and lot number along with target and actual weights. The system can also print one complete ticket for all containers.

- The system will return to the third step in this example batching process, automatically start the next batch, and will continue batching until the total number of programmed batches and containers have been produced. The operator can end the run early by choosing to ‘End Lot’. The system will complete the current batches and then return to “idle mode” screen. The operator may also choose ‘Abort’ to immediately end the batch and return to idle.

Hand Prompt Batching – Validation Process

The following describes the operational process of the Hand Prompt Validation process. It is assumed that one or more batches have already been completed using the Hand Prompt Batching Station software, and that batch container tracking was used.

- The Batching Schedule is entered either remotely through the WebCentral software, directly at the Hand Prompt Batching Station, or through the Mixing Control if integrated into a mixing process. Scheduling involves picking which formula to run and specifying the total number of batches to run.

- The system will analyze the formula to identify the mix instructions. The system will only prompt for the ingredients meant to go in before the current mix to ensure proper order of introduction of the ingredients into the batch. The Hand Prompt Batching Station also identifies the mix instructions and treats them as container breaks so that the required mixer ingredients are guaranteed to be in separate containers.

- The screen will display the first set of ingredient names and codes required by the mixer along with target weights and prompt the operator to scan containers to satisfy the requirements.

- When the operator scans a container, the system will check whether it has the correct raw material ingredients. Any batch container can be used, even containers batched for a different formula, as long as it does not contain any incorrect ingredients. If the container is accepted it will be added to a list of containers for the mixer and the screen will update the actual weights of each ingredient to match the total of all scanned batch containers.

- The operator continues to scan containers, if necessary until all ingredient amounts have been satisfied. The Hand Prompt Batching Station will show a checkmark next to each ingredient within tolerance. By selecting a container in the list, the system will also show how much of each ingredient came out of that specific container. If it is desirable to use a different set of batch containers, containers that have already been scanned can be removed from the list.

- Once all ingredients are correct and within tolerance, the operator will press ‘Confirm’ on the screen. The operator may confirm at any time. However, if there are errors with the ingredients, the system will display a warning message and will not continue. Supervisors with the proper security privileges may override these errors if necessary.

- After final confirmation of the ingredients, the system will prompt the operator to dump the ingredients, if it is integrated into the mixing process, or move on to the ingredients for the next mix if not. If there are no more ingredients for the current mixer batch, it will move on to the next batch required by the mixer, or return to idle if there are no more batches. The operator can ‘Abort’ the run early, immediately returning the system to idle mode.

Hand Prompt Batching Station Applied

A typical Hand Prompt Station control architecture (with some available options) can be composed of one (1) Hand Prompt Batching Controller, one (1) Touchscreen Display, one (1) Keyboard with built-in touch-pad, one (1) Platform Scale (a variety of maximum capacities is available), one (1) Floor Scale (variety of maximum capacities available), one (1) Label Printer, one (1) Wireless Barcode Scanner, and one (1) RFID Scanner.

Customer personnel can establish recipes or formulas for a virtually unlimited number of final batch products using a virtually unlimited number of ingredients. When a batch formula or recipe is initiated the Hand Prompt Controller batching software will ask the operator to weigh ingredients, and will sequence an operator through the selected formula/recipe, one ingredient at a time.The operator can weigh ingredients on one or two scales, depending on how the formula/recipe is designed and how the system is equipped.

The primary advantages of the Hand Prompt Batching Station are to ensure that each ingredient in the chosen formula/recipe is added to the batch container, is within a customer programmable weight tolerance, and that the correct ingredient is added and the ingredient lot has been captured before the Hand Prompt Batching Station will advance the operator to the next ingredient in the formula/recipe to be added. Other major advantages include 1) adapting to your process easily, not requiring your process to adapt to the batching station unlike manual weighing stations available from others, and 2) the Hand Prompt Batching Station database can easily grow and evolve to a larger and automatic micro/minor/major ingredient batching system as your production may require, meaning a larger ROI.

For efficiency and speed, multiple batches can be weighed at the same time by using the “Max Containers per Scale” field on the “Schedule” screen to control how many batch containers are made up at one time, and by setting the “Batch Count” field to be the number of the desired batches that you would like to run at one time.

If the system is equipped with a Hand Prompt Validation Control Panel, its software will prompt the operator to scan the batch containers (having an RFID tag or barcode label), completed by the Hand Prompt Batching Station software, and verify that the ingredients in the batch containers are correct and within tolerances. This validation function is designed to run at the mixer, independent of the Hand Prompt Batching Station software. It can be integrated into the mixing process control or as a standalone function.

The Hand Prompt Batching Station provides real-time records for each batch produced, enabling the highest standards to be maintained by ensuring a consistent product. As batches are produced, the system records the batch data and can optionally print container or batch labels to the ticket printer (if purchased with the system). It can also optionally print full-page reports to a page printer. Additional reports and data can also be printed from the Hand Prompt Batching Station, or remotely via the Sterling Systems & Controls WebCentral Supervisory Control Software. Batching container labels provide a hard copy of each ingredient along with the ingredient lot number and the required and actual formula weights. A time and date are also stamped on each report at the start and end of the batch.

If an alarm condition occurs during the processing of a batch, the Hand Prompt Batching Station will record an alarm message thereby enabling a supervisor to review the performance of the operator and track problems that may occur later. The Hand Prompt Batching Station will maintain its database by automatically performing routine maintenance and backup procedures.

Typical systems will be provided with the WebCentral supervisory software, and ingredient lot numbers will be assigned and entered using WebCentral, or they can be entered directly through the Hand Prompt Batching Station. Ingredient lots can be selected by scanning a lot label when prompted, by selecting them from a list on the screen, by entering them by hand, or on a first-in, first-out basis using the order set up on the lot table. When choosing lots manually, the operator can switch lots in the middle of a weighment if the current lot runs out. When selecting by first in, first out, the first lot in the list for the ingredient is used until its inventory reaches 0, at which point the system switches to the next one for any remaining weight and future weighments.

Please note that the Hand Prompt Batching Station must be put on the same network as any customer PCs that will be using the WebCentral software to view and manipulate data in the Hand Prompt Batching Station database. If there is not a plant Ethernet network infrastructure in place, Sterling Systems & Controls can assist with specifying networking hardware and cabling if needed.

WebCentral™ Features

WebCentral™ is a browser-based supervisory control software application that can be used to access and manipulate data in the Hand Prompt Batching Station from a remote computer. WebCentral is designed to be used on existing plant computers that can access the Hand Prompt Batching Station via an INTERNAL Ethernet network.

Note: WebCentral uses browser technology but it is NOT an internet-based application, so internet access is not required, but the computers that will use WebCentral must reside on the same INTERNAL network. No special software is required to be installed on the client computers other than a standard, modern web browser. WebCentral will work with most any recent browser including browsers on tablets and smartphones.

WebCentral™ features include:

- Add/Modify/Delete Ingredients.

- Add/Modify/Delete Formulas.

- Add/Modify/Delete Batching Schedule Records.

- Add/Modify/Delete Ingredient Lot Information.

- View Reports and Print through the web browser.