Automating Bulk Bag Filling

Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any process, such as bulk bag filling, or a complete facility. Sterling Systems & Controls works with numerous OEM’s to provide them with competitive and efficient automation and process control of the equipment being sold to their customer. Working with many OEM’s is a specialty of Sterling Systems & Controls. Our knowledge of process equipment, and automation, makes us uniquely able to put our more than fifty (50) years of experience to work for a wide rangeof OEM’s, and end users. Automating the bulk bag filling process is an example.

Sterling Systems & Controls has designed and manufactured an automation and process control system for Automating Bulk Bag Filling. This automation and process control system includes a Motor Starter Control Panel. Included in this control panel is an Allen-Bradley PLC with discrete and analog outputs, an Allen-Bradley Panel View Plus 10” color touchscreen, custom automation software including all MOA (Manual-Off-Automatic) switches with running indicating lights, four (4) motor starters, and all necessary fusing, wiring etc. to meet the application requirements. The Motor Starter Control Panel is also interfaced to a pallet disperser PLC using Ethernet IP messaging. Sterling Systems & Controls is a UL-listed control panel manufacturer.

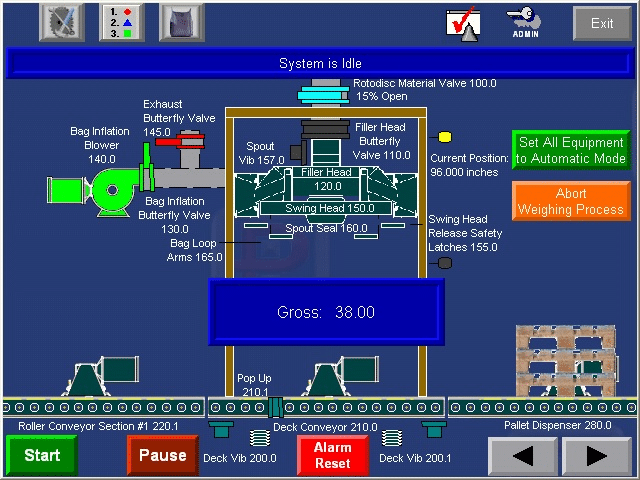

The operator interface touchscreen displays the automated bag filling process. This touchscreen is mounted in the door of the Motor Starter Control Panel provided by Sterling Systems & Controls. The touchscreen has a system overview screen graphically depicting all of the equipment being automated. The operator can adjust operating parameters for the control system at the touchscreen. These parameters include, but are not limited to, equipment timers, weight setpoints and others. Multiple levels of security are also provided as part of the automation system so that adjustments can be made by selected individuals.

Sequence of Operation

- An empty pallet is on the in-feed pallet conveyor. With the system in the Auto mode, if there is a pallet on the conveyor confirmed by a photo-eye and no pallet on the conveyor mounted on the densification deck, the in-feed conveyor will start to index the empty pallet forward. If a pallet in the bulk bag filling station was confirmed by a photo-eye, the in-feed conveyor would hold the pallet in place.

- At the material inlet to the filling station, a surge hopper holds a continuous flow of material while installing a new, empty bulk bag. Mounted to the discharge of the surge hopper is a pneumatically operated slide valve with a positioning actuator. When filling in a fast mode, the valve is fully open. The valve partially closes at the first weight preset for a moderate feed rate. At the next preset, the valve fully closes, and the densification deck is actuated for a preset, adjustable time cycle. When the densification cycle is completed and the scale is stabilized, the valve will partially open to “dribble” the least amount of material and then close when the target weight is achieved.

- The swing-down bulk bag filler head lowers to a position that allows the operator to load a new bulk bag, and then raises to the filling position. The lowering and swinging to a loading position is initiated through a pushbutton (supplied by others in this example). When the operator is ready, the load button is depressed. This signals the 1-1/2 HP motor to reverse, lowering the fill head and releasing pneumatic actuated latches that release the fill head to swing into the loading position. When the operator attaches the bag loops to the fill head, the latches are closed manually. The bulk bag filling nozzle is placed over an inflatable cuff, sealing the bulk bag to the fill head. The operator pushes a button on the fill head to activate the inflatable cuff. The operator also presses a button that actuates the 1-1/2 HP motor to reverse, moving the fill head to the up position. As the fill head moves up, a limit switch closes to actuate a solenoid valve that swings the head into the filling position.

- The fill head includes a fan that blows up the bag to get the bag in the proper shape for filling. A spring-loaded button must be held depressed to allow the fan to operate. When the button is released the fan stops. When the operator believes the bag has been properly inflated, the button is released. This can be going on as the fill head moves to the filling position.

- When the fill head is in the correct height for filling, a limit switch is activated to stop the 1-1/2 HP motor. This switch will activate a timed cycle that will first Tare the scale, and open the slide valve allowing the bulk bag to begin filling.

- During the filling operation, it may be necessary to vibrate the bulk bag to densify the material. This is normally accomplished at various weight setpoints. When this trigger is activated, a set of four (4) bellows are inflated pneumatically to lift the deck away from the load cells before the vibrator starts. Some material requires more vibration than others.

- When the target weight is achieved and the fill valve closes a second time, an adjustable cycle begins that allows the in-flight material to clear the fill chute, the fill cuff deflates releasing the fill nozzle, the latches supporting the bag loops release and the loops fall to release the bag. The fill head then indexes up to a release height, closing the highest limit switch. This is the signal for the powered roller deck to activate, moving the filled pallet onto the staging conveyor and an empty pallet to move forward.

- The filled pallet will move forward indexing to the last photo-eye. If there is already a filled pallet at this position, the pallet will index to the second position. If the second position is filled, the pallet will index to the first position. If filled pallets occupy all of the zones of the staging conveyor, a filled pallet in the Bulk Bag Filling Station will not index onto the staging conveyor until a pallet is removed from the staging conveyor. When a pallet is removed, the staging conveyor will automatically start to index a waiting pallet into that empty position.