Pelleting Feed Mill Automation

Pelleting Feed Mill Automation can simplify operations and improve the efficiency of cost and throughput. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill process or a complete facility.

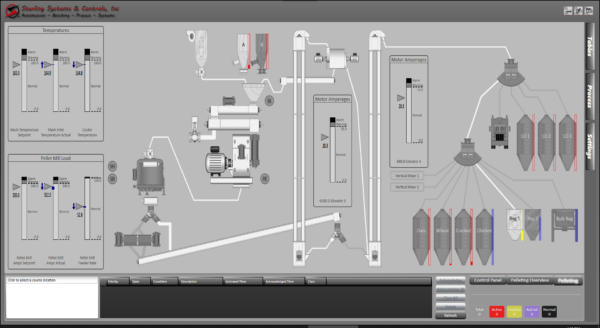

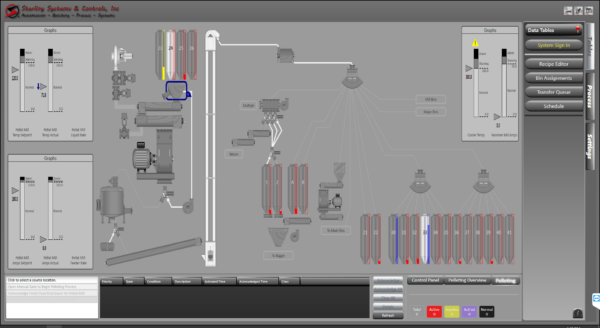

Sterling Systems & Controls designs and provides equipment and software for custom systems using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems & Controls customized Windows-based Automation Software. Sterling Systems & Controls more than fifty (50) years of Feed Mill process and Feed Mill automation experience ensures quality and efficiency in both hardware and software.

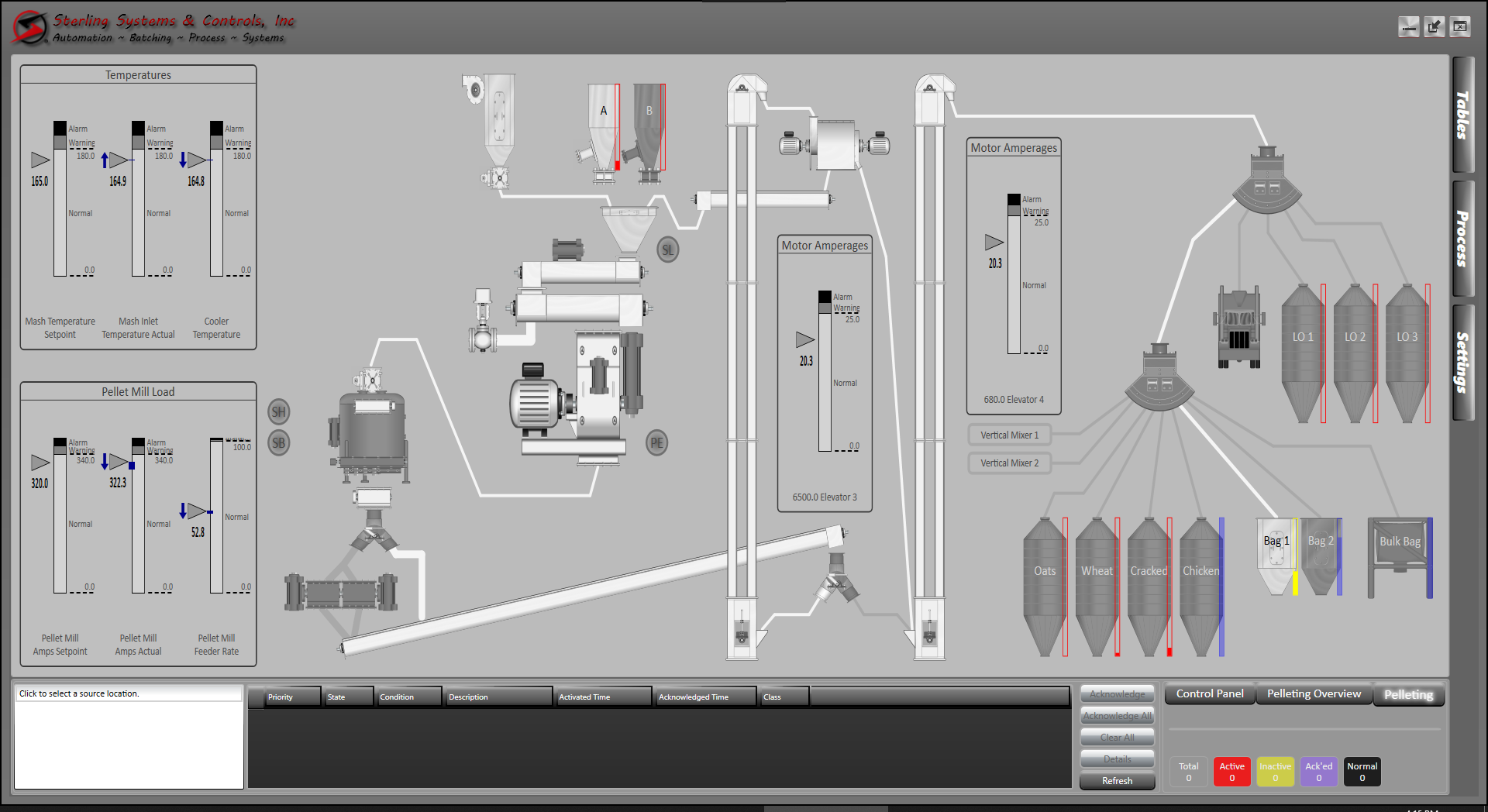

Pelleting

While the pelleting process has historically been done manually, the Sterling Systems & Controls pelleting control system uses your production requirements and formulas to create a customized and fully automated pelleting process.

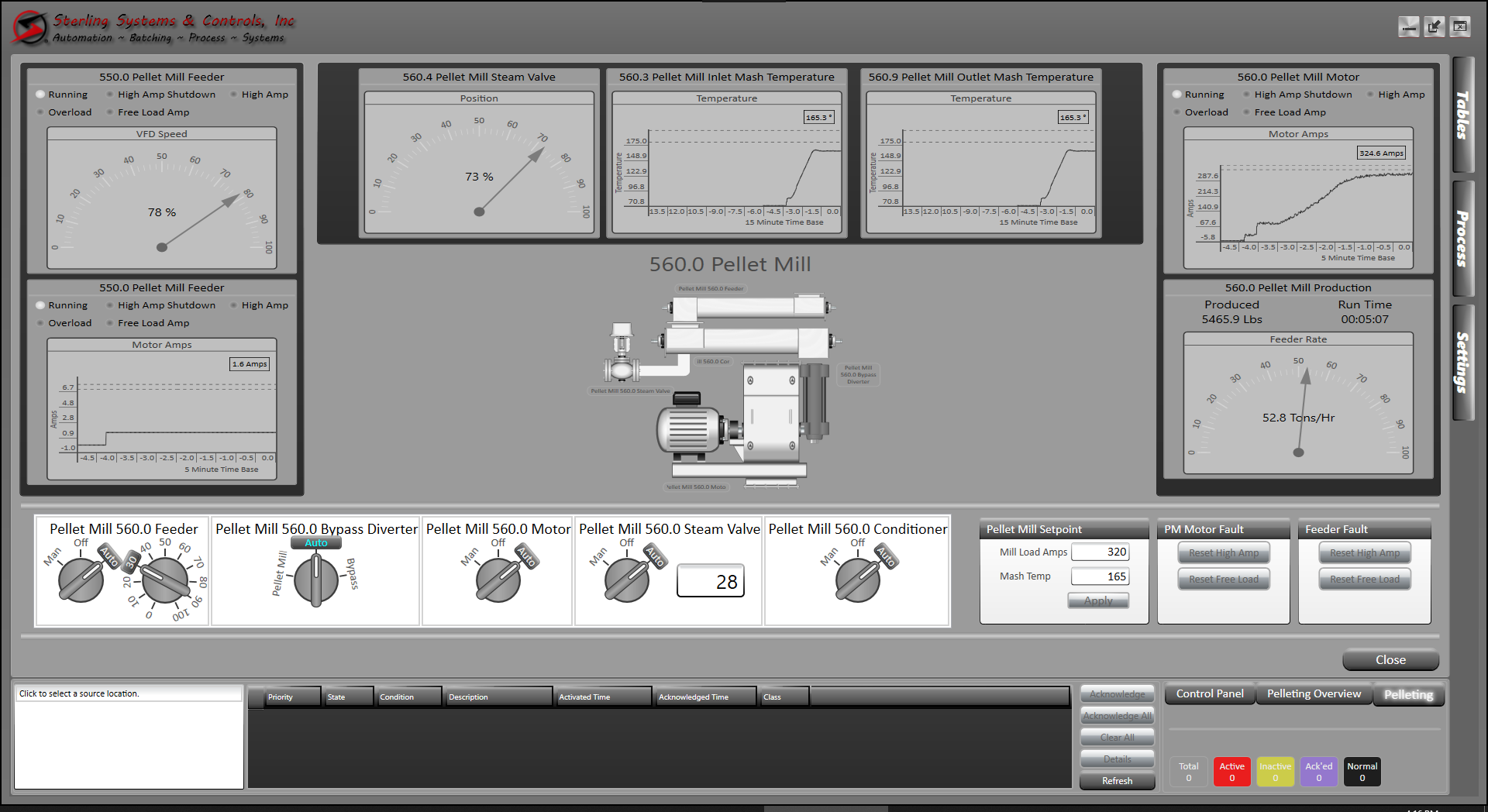

Upon starting the main pellet mill motor, the Pellet Mill Control application will start running the feeder at a predetermined speed when the idle condition on the pellet mill motor is reached.

The startup feeder speed is determined by the hot or cold parameters. After the pellet mill electrical current threshold value is reached (shown on the main pellet mill screen), the steam valve is opened to a preset setting based on hot or cold die parameters.

The Pellet Mill Control application is constantly evaluating the information. Feeder adjustments are made to bring the pellet mill electrical current to target levels. The feeder speed ramps up, and the steam valve also ramps up. The feeder and steam adjustments continue until the current and mash temperature setpoints are reached. This provides for smoother and faster achievement of maximum efficiency with minimum downtime.

When the motor load setpoint is reached, the Pellet Mill Control application adjusts the feeder to maintain the mill at the electrical current setpoint. When the mash temperature setpoint is reached, the Pellet Mill Control application adjusts steam to maintain the mash temperature. This continues for the duration of the pelleting run to keep the pellet mill operating at set parameters for the formula running. The Sterling Systems & Controls, Inc. Pellet Mill Control application optimizes throughput and maximizes output.

Benefits

• Custom-designed pellet mill control application software meets your exact automation and system requirements.

• Integrated mill monitoring and histogram displays.

• Control functions maximize throughput and high output; pellet mill operation is optimized based on mill condition.

• Plug conditions are averted through the use of smart control functions; mill shutdown is automatic if a plugged condition is detected.

Typical Features

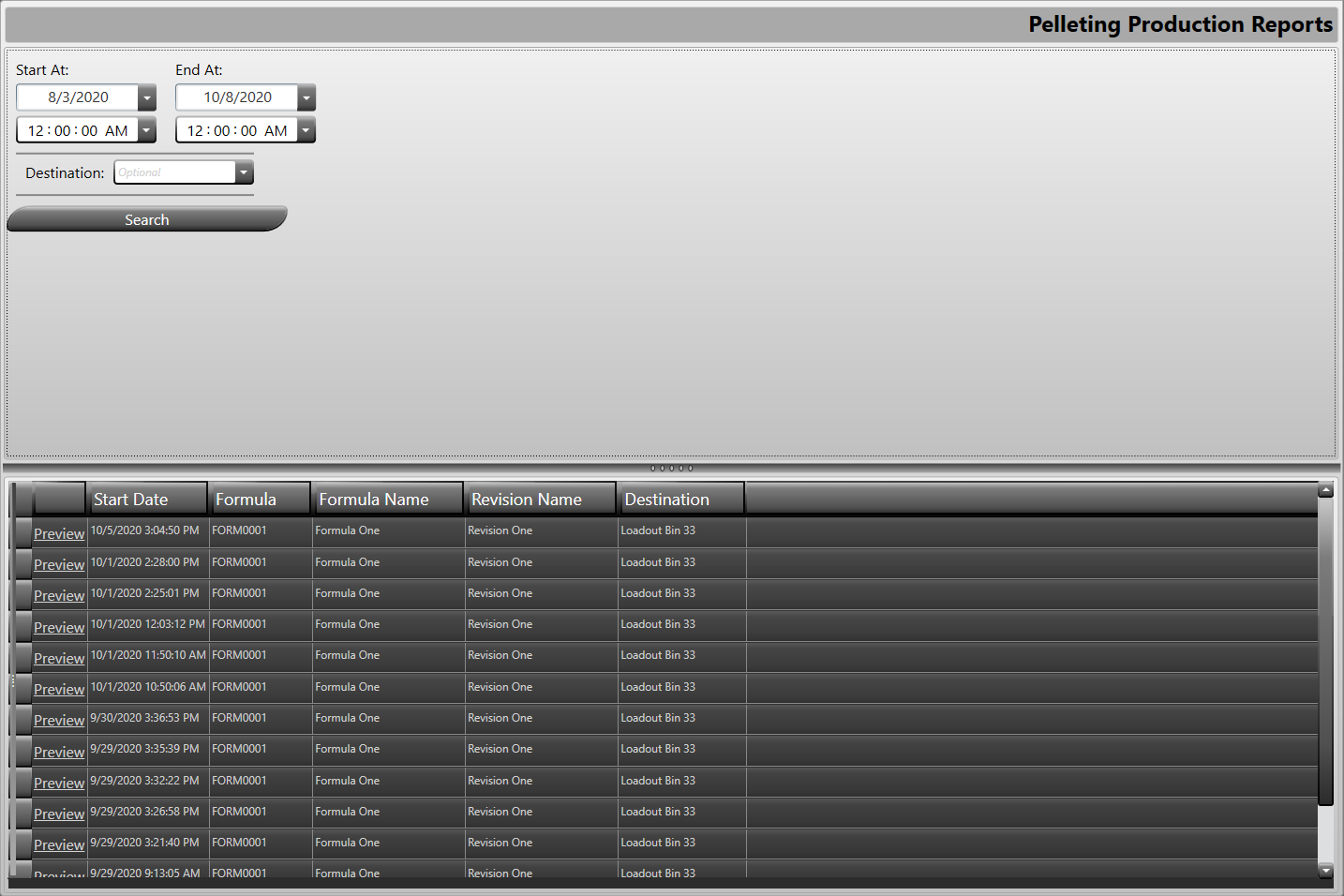

• Pellet Mill Control application controls feeding, pelleting throughput rates and bin assignments.

• Graphic display of all key parameters is provided, including Mash Temp, Feeder Rates, Steam, Mill Current, etc..

• Controls a wide range of Pellet Mill types, quantities and sizes.

• The Pellet Mill Control application utilizes “Smart Control” to monitor mill condition.

• Pellet Mill group parameters can vary widely depending on the type of pellet mill.

• Parameters are easily adjusted if mill conditions change.