Manufacturing Cattle Feed

Manufacturing cattle feed requires precise weighing and batching of a variety of ingredients. Ensuring that the batches are created accurately and that each ingredient lot is tracked carefully is also of great importance. Sterling Systems & Controls automatic cattle feed manufacturing micro ingredient batching systems use a unique approach to batch, blend and deliver ingredients to the mixer for further processing into the finished feed.

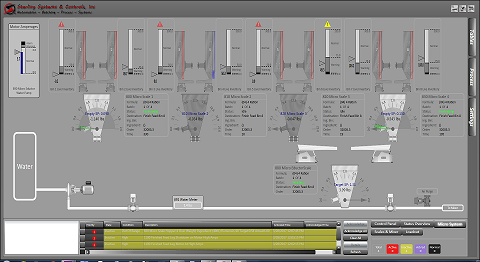

In this application example, the micro ingredient batching system includes eight ingredients, each with its ingredient storage bin. Here is basically what is included in this specific case. Each micro-ingredient system for manufacturing cattle feed can be unique. Sterling Systems & Controls custom engineers equipment and systems to meet your objectives.

Eight (8) 5 cubic foot capacity 304 Stainless Steel Supply Bins

– Hinged Lids.

– Proximity sensors on each lid.

– Perforated grating on the inside bins to prevent bags/trash from entering the bin.

Eight (8) Stainless Steel Vibratory Feeders

– Rated 115V/1PH/60Hz input.

– 304 stainless steel tray, 4″ wide x 24″ long.

– NEMA12 controls rated 115V/1PH/60Hz input.

– Steel-it paint on the drive with stainless hardware.

Four (4) Stainless Steel Micro Scales

– 304SS construction, highly polished to enhance ingredient flow.

– Approximately 0.9 cubic foot capacity.

– Single Point Load Cell Configuration.

– Vibrator Channels with vibrators.

– 4” butterfly valve, uses ferrules/quick-disconnect clamp to attach to scale hopper.

Two (2) Stainless Steel Vibratory Conveyors

– Rated 115V/1PH/60Hz input.

– 304 stainless steel tray, 6” wide x 36” long.

– NEMA12 controls rated 115V/1PH/60Hz input.

– Steel-it paint on drive with stainless hardware.

One(1) Carbon Steel Supply Bin Support Frame

– Steel-It Paint Finish.

– Removable Bins for cleaning and maintenance.

– Heavy Duty Construction.

One (1) Carbon Steel Scale Support Frame

– Independent Scale Frame to eliminate motion while filling bins.

– Steel-It Paint Finish.

– Heavy Duty Construction.

– Shrouded for the skirt to prevent erratic scale readings.

One (1) Liquid Eductor System (for use in transporting/blending dry ingredients) with load cells

– 304SS construction, highly polished to enhance ingredient flow.

– Approximately 0.9 cubic foot capacity.

– Positive Displacement Pump.

– Shut-off Valves, Cone Hopper with rinse nozzles, Brass Eductor, Air Purge.

One (1) SCR Starter Panel

– NEMA12 Mild Steel Enclosure.

– Eight (8) SCR Controllers, variable speed.

– Pre-Assembled & Tested.

The Liquid Eductor System performs the purpose of transporting the dry material ingredients, and the blending of those ingredients with a primary fluid (most always water) used in the batching process. The blend fluid, with ingredients, is delivered to the mixer.

Sterling Systems & Controls doesn’t just provide the mechanical systems for these cattle feed manufacturing operations. Batching controls and automation is also provided. The batching computer controls and maintains formulas/recipes, ingredient inventories and usages, bin assignments and ingredient locations, lot tracking and validation, and formula schedules or stack-ups. The batch controller will have the capability to simultaneously weigh all scales while the mixer processes hand-add liquid additions and mixing times for previously started batches and formula setup. The finished mixed feed is then discharged into the mixer surge hopper, then transferred to the designated Loadout bin.

Sterling Systems & Controls custom engineers cattle feed manufacturing systems for a variety of operations. Size, rates, and accuracy are all engineered to meet specific objectives.