Loadout Feed Mill Automation

Feed Mill automation can simplify operations and improve the efficiency of cost and throughput, including the Loadout Feed Mill Automation process. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill process or a complete facility.

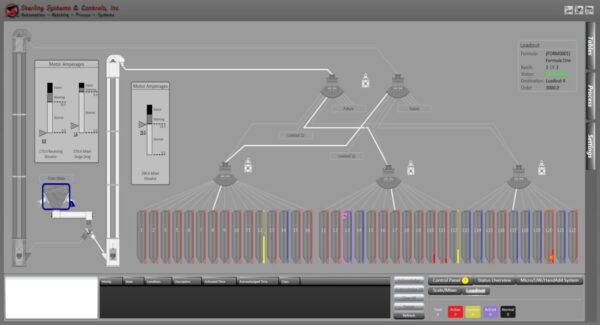

Sterling Systems & Controls designs and provides equipment and software for custom Loadout Feed Mill Automation systems using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems & Controls customized Windows-based Automation Software. Sterling Systems & Controls more than fifty (50) years of Feed Mill process and Feed Mill automation experience ensures quality and efficiency in both hardware and software.

Loadout

As with our other Feed Mill automation application software, Sterling Systems and Controls Loadout Feed Mill Automation system ensures that the transport of the correct product goes to the correct and desired location, quickly and efficiently, with superior accuracy.

With the ability to custom-fill a truck with multiple orders, the Loadout system identifies the load going into the truck trailer and then fills it with the correct load.

From beginning to end, Sterling Systems & Controls delivers accuracy and dependability, validating that all product is loaded into the correct truck, into the correct compartment and delivered to the correct customer.

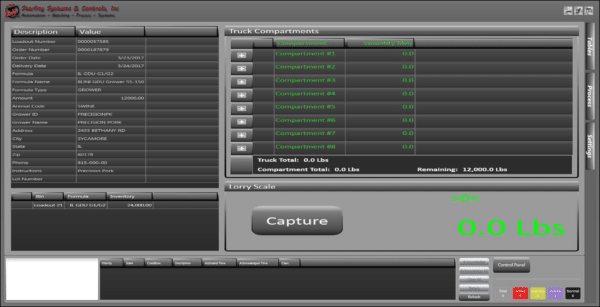

To accomplish the Loadout function accurately and efficiently the truck loadout process screen is used and typically consists of three tables. The table located on the right of the screen lists all the truck compartments that will be weighed into. The table located at the bottom right-hand corner of this screen lists only the Loadout bins containing the formula ordered.

Benefits

• Custom-designed Loadout software application to meet your exact requirements.

• Ensures feed delivery integrity and validation.

• Superior accuracy and performance.

• Easy to use, flexible and superior data management.