Feed Mill Automation Receiving & Transfer

Feed Mill automation receiving and transfer can simplify operations and improve the efficiency of cost and throughput. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill automation process, such as Feed Mill automation of material receiving and transfer, or a complete facility.

Sterling Systems & Controls engineers and provides equipment and software for customer-specific objectives and requirements using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems & Controls customized Windows-based Automation Software.

Sterling Systems & Controls more than fifty (50) years of Feed Mill process and automation experience ensures quality and efficiency in both hardware and software.

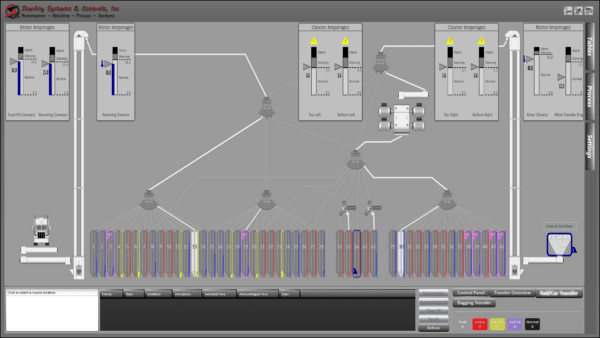

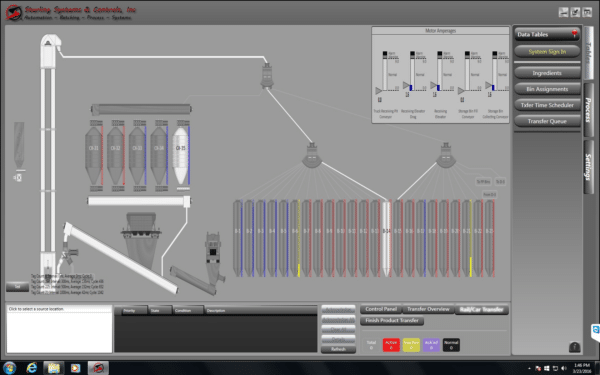

Receiving / Transfer

The receiving/transfer application is custom-designed to suit your exact needs. This includes allowing for only manual control or including the ability to allow for automatic receiving and transfer steps.

A fully automatic receiving & transfer application accurately tracks and transfers incoming grain and commodity materials to the correct location within your facility each time.

Truck or rail car transport of incoming materials can be accommodated. Feed rates are controlled to maximize efficiency and material safety. After the material has been moved into the containment location (bin, etc.) the system logs and weighs empty trucks before they leave the facility. Weight measurements are logged into the material tracking function, maintaining accuracy and traceability.

The Transfer function connects your Feed Mill. It guides the movement of your grains, other commodities, and finished products from one process point to the next. The Transfer function allows you to control material movement between receiving and loadout. This ensures the safety of your produced feed and the accuracy, speed and efficiency of the production process.

The Receiving & Transfer application is vital in protecting against material contamination, managing shared equipment, distributor head functions, container filling/discharge, and material transfers within containers, providing safe and fast transfers.

Benefits

• Faster off-loading of grain and commodities.

• Meet traceability and validation requirements with material tracking.

• Better reports for management by vendor, farmer, truck/rail company.

• More efficient, greater productivity due to easy operation and better knowledge of what you have and where it is.

Typical Features

• Receive materials by truck or rail.

• Automated routing – interlocks or manual operation.

• Include shipping and transfer functions.

• Simple data entry.

• Modern graphic displays.

• “Point & Click” movement of material from point A to B.

• Integrate with ERP system or other third-party software.

• Grinding and Use bins auto refill with level indication.