Batching Feed Mill Automation

Feed Mill automation can simplify operations and improve the efficiency of cost and throughput. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill process or a complete facility, including Batching Feed Mill Automation. Sterling Systems & Controls designs and provides equipment and software for custom systems using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems & Controls customized Windows-based Automation Software. Sterling Systems & Controls more than fifty (50) years of Feed Mill process and Batching Feed Mill Automation experience ensures quality and efficiency in both hardware and software.

Batching

Sterling Systems & Controls, Inc. can automate your batching systems, whether a multiple scale ingredient batching system (micro, minor, major weighments) provided by us or any other vendor, or any weighing system for finished feed or feed in process. Our batching control systems improve the efficiency of your dry or liquid material batching process. We specialize in custom designed batching systems to increase performance, and consistency, eliminate waste, combine dry and liquid ingredients, and provide unsurpassed production data collection and reporting capability.

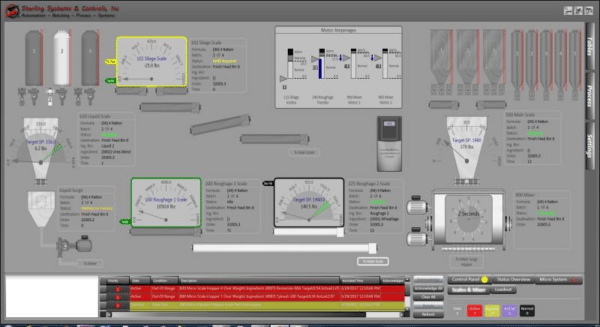

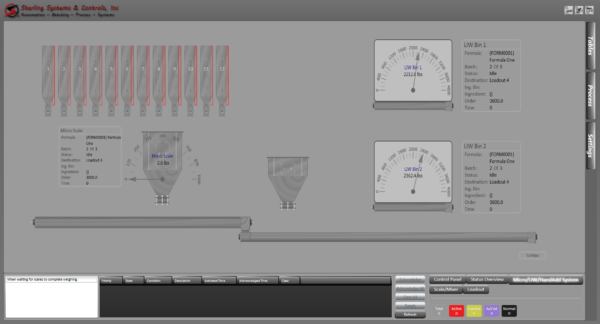

The main operator interface of the Sterling Systems & Controls batching control automation system is a desktop PC with Windows operating system running the Sterling Systems & Controls custom-designed batching application and a custom database application. The PC and Sterling Systems & Controls applications provide all control, data storage, and equipment status information necessary to run the batching process. Access to the various screens, features and functions of the batching application, including Mixer control, is accomplished by using the pull-out panels located at the right side of the screen. Most screens or features will be read-only and editing functionality will be available to a signed-in user with the proper operating privileges.

Benefits

• Custom-designed software application to meet your exact automation and system requirements.

• Superior accuracy and performance with better throughput and high resolution possible.

• Meet feed safety and traceability requirements.

• Remote supervisory control and ERP system integration are available.

Typical Features

• Can incorporate multiple ingredient applications of virtually any quantity, e.g. 20, 30, 40, and more.

• Virtually unlimited number of formulas.

• Multiple scale designs easily accommodated.

• Lot tracking, ingredient traceability and batch validation with barcode or RFID scanning available.

• Variety of supply bin sizes, and types, including supporting bulk bags and totes.

• Integrated control of a range of Mixer types, sizes and quantities.