Mixer Bowl Batching System Upgrade

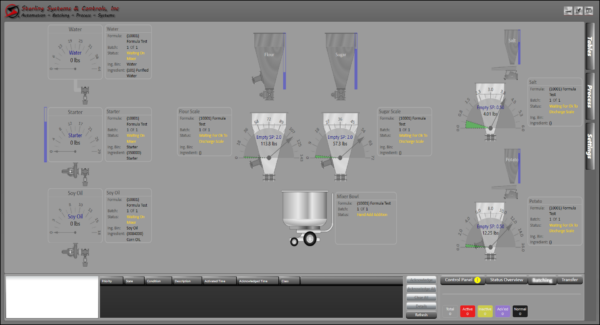

A customer asked Sterling Systems & Controls, Inc. to analyze their existing batching system and make recommendations as to how it could be improved. The result was a request for Sterling Systems & Controls to perform a mixer bowl batching system upgrade. Upgrades were identified and a revised system was custom-engineered to reduce the manual handling of batches, eliminate equipment, and increase production capacity. The original system was supplied by Sterling Systems & Controls in the mid-1990’s old and well-used. An updated design was proposed to increase the batch size by ten (10) times to reduce the number of mixes for the customer. This also reduced the handling of the small mixer bowls and the associated conveyor equipment to move the bowls and the mixers. The new/upgraded system would also replace scaling equipment for both dry and liquid ingredients, including the scales and liquid meters. The batching control system was also updated to include formulation, inventory, lot tracking and data acquisition.

Customer objectives for upgrade included:

– Reduce cleaning.

– Reduce maintenance.

– Have mixer bowl in a single location for batching.

– Create best configuration stack-up of equipment for optimal processing.

– Eliminate existing equipment stack-up.

– Have oil and starter metered directly into the mixer bowl rather than weighed and discharged.

– Include new water meter.

– Size scales for flour, based upon larger formula.

– Size scale for sugar, based upon larger formula.

– Salt and potato flake supply bins with low-level indicators, vibratory feeder, scale hopper w/ gate.

– Automation for flour and sugar pneumatic conveying systems (reuses existing equipment).

Process control considerations included:

– Update PLC panel to Allen Bradley PLC and current technology of weight instruments.

– Upgrade four (4) weight instruments (flour, sugar, salt & potato flake).

– Add a local control panel to the equipment frame with remote I/O; eliminate wiring.

– Update PC software to next generation Windows OS.

– All devices will be on Ethernet (PLC, PC, weight instrument, etc.).

– Reuse existing motor starter panel; maintain hard wiring between PLC and motor starter panels.

– Airlocks will be on VFD’s.

Sterling Systems & Controls supply for this mixer bowl batching system upgrade project included:

- Transitions.

- Airlocks.

- Chutes.

- Scale Hoppers (flour, sugar).

- Starter liquid flowmeter.

- Oil liquid flowmeter.

- Water liquid flowmeter.

- Use bin and scale hopper support frames.

- Salt system including bin, low-level probe, feeder, scale hopper, load cell, gate valve.

- Potato flake system including bin, low-level probe, feeder, scale hopper, load cell, gate valve.

- Batching System software upgrade, new back panels, PLC, operator interface and others.

- Adds to existing motor starter control panel.

- New remote equipment control panel with weight instruments for new scale hoppers and other.

- Complete engineering services, including onsite and remote commissioning and support.

- Modified Stackup.