Food Ingredient Batching

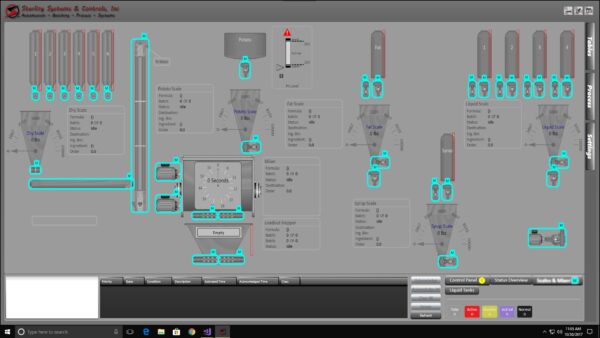

Sterling Systems & Controls, Inc. offers food ingredient batching systems for liquid and dry products. Automation systems can be provided for virtually every aspect of the food manufacturing area. This includes raw material handling systems, such as pneumatic & mechanical conveying, liquid systems (weighing & metering), mixer automation, and dry powder batching systems. Dry powder systems include bulk bag filling/packaging, bulk bag unloading and weighing systems, minor & major bag weighing systems, and ingredient batching systems. In addition, a dry food powder processing system can include packaging systems.

Common applications include dry & liquid mixes, batter mix, and powder & liquid drinks. In addition, health food & bodybuilding products, spice mixes, and various bakery ingredients. Dry product food ingredient batching weighment size can be classified into three categories: micro, minor, and major. The automatic batching system can be focused on just one type of weighment size, but often incorporates micro, minor and major ingredient weighments.

Food ingredient batching control system can include:

- Formulation Management & Storage.

- Raw Material Management, Inventory and Usage.

- Ingredient Material Parameters (Weighment Tolerance, Feeder Speed, Jog, Pre-act/Cutoff).

- Ingredient Lot Tracking (Barcode, RFID).

- Batch Validation (Barcode, RFID).

- Equipment Parameters (Scales, Mixer, Dry Ingredient Feeders, Liquid Meters).

- Temperature Monitoring.

- Mixer Load Tracking.

- C02 System Automation.

- Finished Batch Tracking.

- Abnormal Condition Alarms and Tracking.

- Remote Process Status & Data Access Software (WebCentral).

- Troubleshooting & Diagnostics Features (Local & Remote).

- Bulk Conveying System Automation.

- Bulk Bag Filling/Packaging.

- Bulk Bag Unloading.

- Bulk Liquid Handling System Automation.

- Micro, Minor, Major Ingredient Automation.

- Semi Automatic: Hand Prompt.

- Mixer Automation.

- Packaging Interface – Yield System Automation.

- CIP (clean in place) System Automation.