Cattle Feed Batching Control

Sterling Systems & Controls, Inc. has served the cattle ranching industry for many years. It is not unusual that Sterling Systems & Controls has been asked to upgrade a cattle feed batching control system after years of use of the initial system. Technology changes and so does the needs of the customer. This application highlights one such upgrade. The requirement was for an upgraded customized Cattle Feed Batching Control software system.

The upgraded Cattle Feed Batching Control system utilizes a rack-mounted PC with Windows OS running a Sterling Systems & Controls Windows-based batching software control system. The main operator interface for the Cattle Feed Batching Control system is via a PC with Windows running a custom-designed Sterling Systems & Controls batching application and Windows Server running all dependent services and databases. The computers and Sterling Systems & Controls applications provide all control, data storage, and equipment status information necessary to run the batching process.

Operation is made simple by using the standard Windows pull-down menu or the toolbar shortcut icon buttons. The system only displays the necessary functions that the operator requires at each level of the process. Formula data entry is fully programmable with the sequencing of dry ingredient additions along with the hand-add additions, which are all programmed by the operator under a security code.

Control System Setup

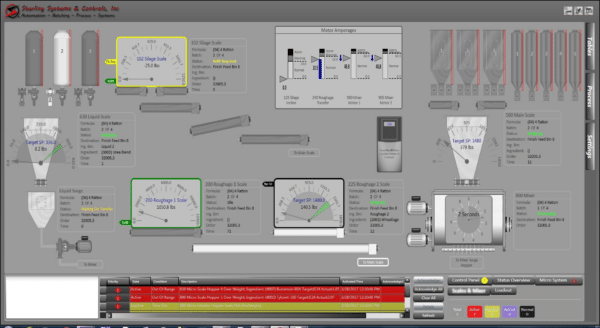

The menu-driven Cattle Feed Batching Control system makes it easy to use and learn. Formula data entry is fully programmable; the addition of dry, liquid and hand-add ingredients, sequencing of the ingredients into the mixer from the scale, and hand-add additions are programmed by the end-user under a security code. When the control system is operating, the display continuously indicates the batching status information in the graphic mode (ingredients, required weights, actual weights, timing functions, etc.). Alarm conditions, should they occur, are also displayed and logged.

Some of the software capabilities include but are not limited to, the following.

- Formula Storage – Storage for unlimited formulas.

- Formula Sequences – Fifty (50) sequences or instructions per formula.

- Ingredient Storage – Storage for an unlimited number of ingredients.

- Multiple ingredient batch control; Loss In Weight Boxes, Major Ingredients, Liquid Ingredients and Hand-Add additions.

- Dual Accumulators for each ingredient (Inventory & Usage).

- Programmable (On/Off) Automatic cutoff compensation for each ingredient (final cutoff signal is automatically adjusted for each batch to compensate for free fall material).

- Plus and minus adjustable tolerance band for each ingredient.

- Purge control (variable time).

- Automatic checks for abnormal conditions with alarms.

- Independent manual backup controls included.

- Scale increments programmable.

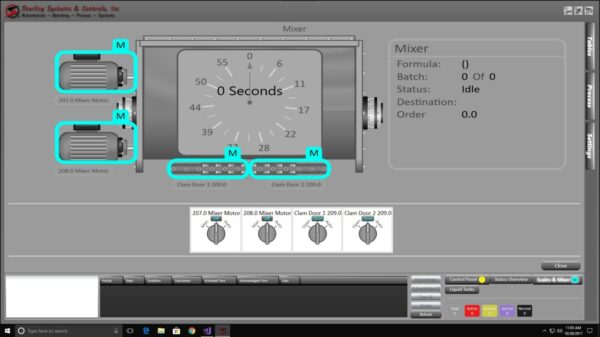

Batching Process Screen

While viewing the Batching Process, text messages are displayed in a status window. In addition, the batching status may also be viewed in complete text form. Each alarm condition that occurs is logged so it can be printed out at a later time. This window will show the date and time the alarm took place and the alarm message.

This is but a small piece of the upgrade provided and is shared to illustrate some of the control and automation capabilities.