The Essential Role of Controls and Automation in Process Manufacturing

In today’s quickly changing industrial landscape, process manufacturing—including industries such as food, baking, pet food, livestock animal feed, chemicals, plastics, and rubber—faces the constant challenge of adapting and balancing efficiency, quality, and safety. These manufacturing industry segments involve complex processes that require precise control, coordination, and data management. From mixing ingredients in a food plant to managing chemical reactions in a lab and the regulatory compliance requirements that exist in almost all these industries, the demand for consistent and reliable production has never been higher.

This is where industrial automation and controls come into play. These systems are designed to optimize operations, improve accuracy, and eliminate or significantly reduce human error. They integrate a wide range of technologies and techniques to manage and monitor manufacturing processes in real-time. Embracing automation isn’t just about keeping up with the latest trends; it’s about pursuing manufacturing excellence in your operations to achieve better results and stay competitive.

Automation has become critical to maintaining the highest of standards across a wide range of manufacturing sectors. In pet food manufacturing and food processing, automated control systems ensure product quality, which is of high importance to nutritionists and dieticians that have created recipes to achieve specific objectives for the intended consumers. While in the chemical industry, they safely monitor and control some of the most toxic and explosive hazardous materials. The flexibility and efficiency provided by these systems can innovate and reinvent operations, allowing manufacturers to respond quickly to market demands and operational challenges.

As we explore the impact of industrial automation and control systems on manufacturing, it’s clear that the involved technologies offer substantial benefits beyond mere automation. They enhance productivity, ensure product consistency, and improve safety for consumers and workers. Understanding how these systems work and their advantages can help you make informed decisions about their implementation and use to leverage them for maximum benefit.

Driving Efficiency Gains with Automation

Efficiency is a critical factor in process manufacturing, and industrial automation systems are indispensable tools for enhancing it. By implementing automation for both simple and sophisticated processes, these systems minimize the need for manual intervention, thereby reducing errors and inconsistencies. This, in turn, drives efficiency gains by accelerating production by speeding up repetitive tasks, optimizing resource usage, reducing operational downtime, and enhancing data precision.

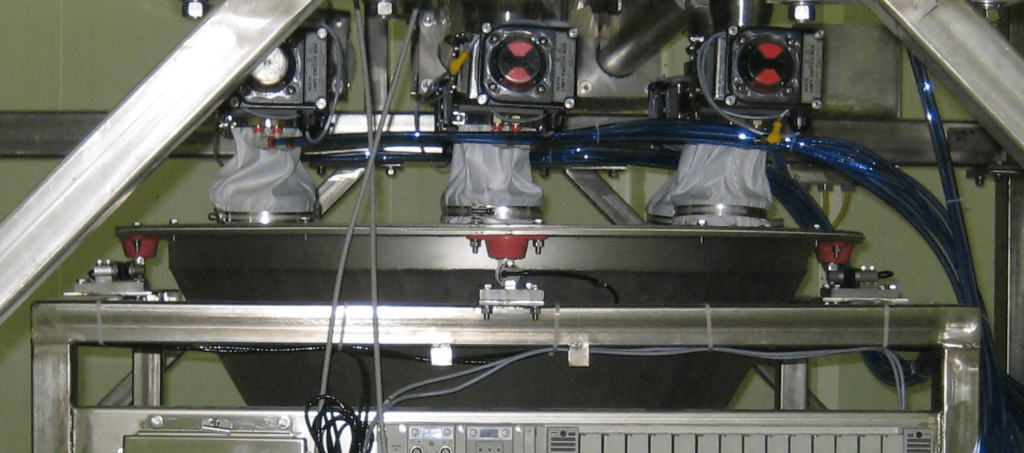

In industries like food processing, automation systems manage everything from ingredient batching and mixing to cooking and packaging. This level of automation speeds up production and ensures that processes run correctly without frequent interruptions. For example, automated ingredient batching systems can add multiple dry material ingredients into multiple scale hoppers at optimal rates to increase batching system capacity by significant levels. A ten-fold increase over manual batching operations is not unusual. In addition, automatic cooking systems can adjust times and temperatures based on real-time data, leading to more consistent product quality and less waste.

Moreover, automation helps streamline maintenance and operational management. Preventative maintenance, powered by machine and process data, can proactively schedule maintenance of equipment before failures occur. This results in a reduction in unplanned downtime and can extend the lifespan of machinery. This proactive approach enables manufacturers to keep production lines running efficiently and avoid costly interruptions.

Delivering Reliable and Uniform Results

In process manufacturing, ensuring high quality and consistency is non-negotiable, and process control systems are critical for achieving both. These automation systems often use advanced sensor technology and control components to monitor and adjust measured process variables in real-time, such as temperature, pressure, flow rates, material weight, and analytical measurements.

Take the chemical industry, for instance. Keeping a tight rein on reaction conditions is critical to ensuring the final product meets your required standards. Automated control systems are great for this—they can monitor your process around the clock and make real-time adjustments to avoid any hiccups that could negatively impact the product’s effectiveness or safety. This means you end up with a more reliable, uniform, and consistent product that is crucial for meeting industry standards, keeping customers happy, and developing brand loyalty.

Additionally, automation makes it easier to keep thorough records and track every step of your production processes. This detailed documentation is crucial for upholding quality control standards and provides the required data for audits and regulatory compliance. By ensuring that everything is meticulously recorded and monitored, automation and control systems boost the reliability and safety of the final product.

Boosting Safety and Mitigating Risks

Safety is a paramount concern in any work environment, particularly in process manufacturing when dealing with hazardous materials and high-risk environments such as hazardous dust or vapor. Industrial automation and control systems play a significant role in making the workplace as safe as possible by automating dangerous processes and reducing or eliminating exposure to risks for your people.

In industries such as rubber manufacturing, automated control systems handle processes that involve high temperatures, and toxic chemicals. By automating tasks involved with the handling, processing, and manufacturing rubber compounds, manufacturers can minimize the risk of accidents and health issues for workers.

Additionally, automation systems can provide advanced safety features like emergency shutdown protocols and fail-safe operation for equipment and processes. These features are custom-engineered to react swiftly if something goes wrong, helping to prevent accidents and protect your team and equipment. For example, in the grain processing and livestock feed industries, automation systems monitor grinders and milling machines used for particle size reduction of grains. They monitor bearing temperature, mill speed and vibrations. If any of these metrics indicate a potential problem, the control system can trigger a safe shutdown sequence to prevent damage or unsafe conditions, ensuring that everything stays running smoothly and safely.

Data is All – Harnessing the Power of Data

We are in the era of digital transformation, and GIGO (garbage-in, garbage-out) has never meant more. Data is a high-value asset and industrial control systems can and must excel at harnessing all the data available. These systems gather extensive data on your manufacturing process, providing insights that can drive continuous improvement.

Automation systems are essential for precise ingredient batching, product consistency, and quality control in pet food manufacturing, particularly when handling dry ingredients. For instance, automation systems monitor and manage the batching of ingredients such as grains, proteins, and vitamins in a facility that produces dry pet food. The control system collects real-time data on ingredient quantities, batching system production rates, and mixing times. If the system detects any deviations from the planned recipe ingredient ratios, it will notify operations personnel and take appropriate action.

By integrating data gathered by automation and control systems with other systems such as your ERP, data analytics in the ERP can be leveraged. You can streamline the batching process, reduce ingredient waste, and enhance overall product quality. This approach improves operational efficiency and ensures that every batch of pet food is nutritionally balanced as designed by the nutritionist, meeting both safety standards and customer expectations.

Adaptability

Flexibility is a crucial advantage in fast-changing industrial process manufacturing markets, and industrial automation systems offer significant adaptability. These systems can be easily reconfigured or reprogrammed to accommodate new products, processes, or production requirements.

In the pet food manufacturing example, automation systems can switch between different recipes and packaging formats with minimal downtime. This adaptability allows manufacturers to respond swiftly to changing market demands, seasonal variations, or new product launches. By enabling rapid changes in production setups, automation and control systems help businesses stay competitive and agile in a dynamic market environment.

Welcoming Technological Advancements

Industrial automation and control systems are evolving rapidly, incorporating cutting-edge technologies such as the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning. These advancements enhance automation systems, offering the potential to make them more effective.

IIoT sensors could provide real-time data on equipment status and environmental conditions, enabling remote monitoring and control. AI algorithms might be used for data analysis to optimize production and drive preventative tactics proactively dealing with potential issues. Machine learning may be used to improve by learning from past performance. Together, these technologies provide potential for driving innovation and to elevate manufacturing to new heights.

Resource Management

Efficient resource management is essential in process manufacturing, and automation plays a key role in optimizing the use of resources such as raw materials, energy, and labor.

In the chemical industry, automation precisely manages the flow of raw materials and energy consumption. This reduces costs, minimizes waste and environmental impact. By optimizing resource use, automation contributes to sustainable and cost-effective operations.

Additionally, automation helps improve labor efficiency, reducing the need for manual handling and repetitive tasks. Employees can focus on more value-added activities and strategic tasks, enhancing overall productivity and resource management.

Remote Monitoring and Control

The ability to monitor and control manufacturing processes remotely is increasingly important in today’s globalized and fast-moving business environment. Industrial automation and controls provide remote management capabilities, enabling operators to oversee and manage processes from anywhere.

This capability is particularly useful for managing multiple facilities or handling operations outside regular business hours. Remote monitoring allows for quick responses to issues, even if operators are not physically present. This ensures continuous operation and minimizes the impact of potential disruptions, contributing to overall operational efficiency and reliability.

Conclusion

As process manufacturing has continued to evolve, industrial automation has become increasingly crucial to the quest for manufacturing excellence. These automation and control systems drive efficiency, ensure quality, enhance safety, and optimize resource use.

Automation systems streamline complex tasks, taking operational efficiency to new heights and minimizing equipment and process downtime and waste. In industries where precision is critical, like food and pet food manufacturing and chemicals, these systems ensure your product meets strict quality standards. This fosters customer trust and brand loyalty and aids with regulatory compliance.

Safety is a major benefit of automated control systems, which reduce human error and exposure to hazardous conditions. This leads to safer workplaces and more reliable operations.

The integration of process-acquired data with ERP systems, IIoT, AI, and machine learning offers opportunities for continuous improvement. Real-time data and advanced analytics help manufacturers optimize processes, proactively address maintenance needs, and swiftly address issues, thereby enhancing process performance and adaptability.

Automation’s flexibility allows manufacturers to adjust to new products and market demands quickly, ensuring agility and competitiveness. This adaptability is key in most process industry markets.

In summary, industrial automation and control systems provide significant benefits by improving efficiency, quality, safety, and decision-making. Investing in these systems positions your business for future growth and resilience, helping you stay ahead of the competition and maintain high standards in a rapidly advancing industry.

Next Step

Automation and controls can be a big plus in improving your industrial manufacturing operations! With over 50 years of expertise in custom engineering industrial automation and control systems, material weighing, ingredient batching, bulk bag handling, liquid handling, and other bulk material handling solutions for a wide range of process industries, Sterling Systems & Controls proudly has the experience to provide you with expert guidance to achieve your automation and process improvement goals. Contact us today to discuss how our knowledge and expertise can align with your goals and how you can continue your journey toward manufacturing excellence!