Streamlining Micro Ingredient Batching with Advanced Solutions

Micro ingredient batching systems allow for precise measurement and batching of small quantities of additives or ingredients. These systems play a crucial role in process manufacturing by ensuring accurate and consistent addition of ingredients.

Commonly referred to as “micro systems” or “micro ingredient systems,” these technologies are particularly vital in animal feed manufacturing, where precise dosages impact nutritional content, animal health and attributes, product quality, production costs, and regulatory compliance.

This blog post explores advanced techniques in micro ingredient systems and reviews the benefits of using these innovative systems in various applications.

Understanding Micro, Minor, and Major Weighments

To fully grasp the scope of advanced batching systems, it’s essential to understand the distinctions between micro, minor, and major weighments.

Definitions and Terminology

- Micro Weighments: Involve the precise measurement of very small ingredient quantities, typically up to 50 lbs.

- Minor Weighments: Refer to somewhat larger quantities, usually between 50 to 150 lbs.

- Major Weighments: This category involves larger ingredient amounts exceeding 150 lbs.

Generic Use of the Term “Micro Ingredient Batching System”

In specific industries, particularly in animal feed manufacturing, the term “micro ingredient batching system” is often used broadly. Despite its name, a “micro system” can include micro, minor, and major ingredient weighments, making it versatile for various recipe batching needs.

What are the “Advanced Techniques” Used in High-Performance Micro Ingredient Batching Systems

Implementing advanced techniques in these systems significantly enhances their efficiency and accuracy.

Precision Weighing Technology and Scales

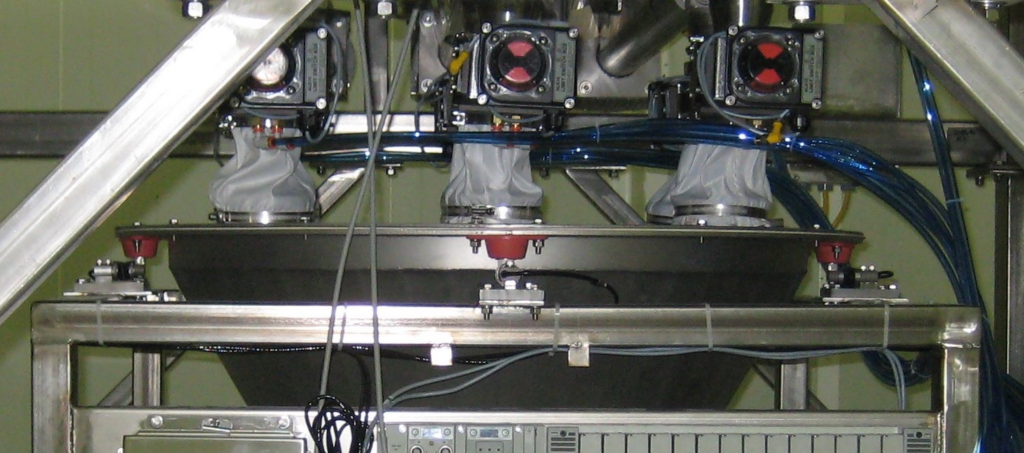

The foundation of any high-performance micro ingredient batching system lies in precision weighing technology. High-resolution scales can offer exceptional accuracy, ensuring that even the smallest quantities are measured with high fidelity. Scale design, size, capacity, and load cell accuracy will impact the overall performance of the scale(s). To ensure micro system throughput capacity meets demand, multiple scales are often required and a best practice for micro ingredient systems.

Automated Dispensing/Feeding Solutions

Advanced systems frequently integrate automatic dispensing or feeding solutions, streamlining the batching process. Automatic ingredient feeding minimizes the need for manual intervention, thereby reducing human errors and ensuring consistent ingredient addition. Moreover, these automated systems operate faster than those utilizing manual feeding methods, which boosts throughput.

Data Management and Integration

Effective data management is another cornerstone of these advanced micro systems. Real-time data collection and processing enable quick adjustments and feedback, optimizing the efficiency of the production line.

Seamless integration with existing systems, such as ERP software, provides enhanced control over the entire manufacturing process. This integration also facilitates ingredient lot tracking and batch validation, ensuring regulatory compliance and maintaining high standards.

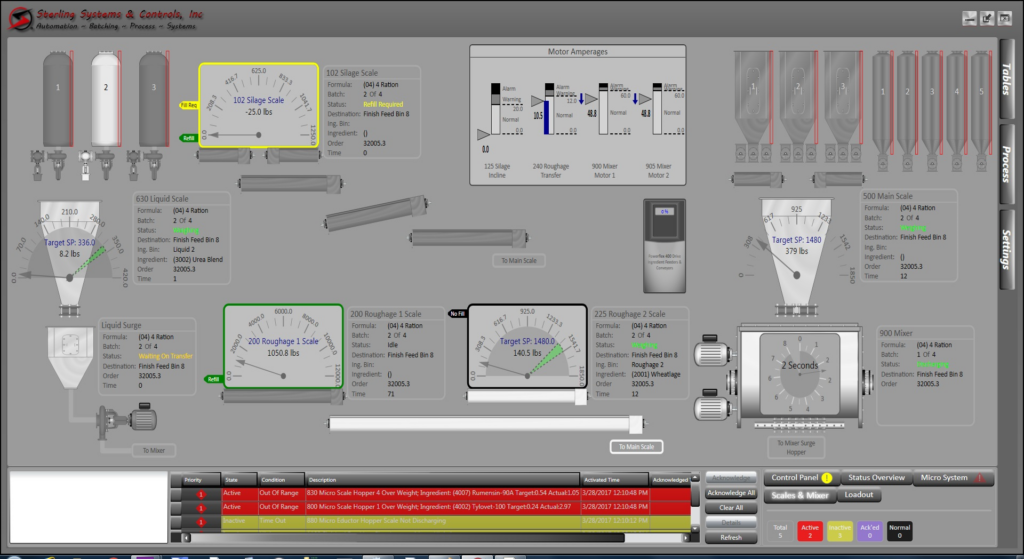

Advanced Batching Control Systems

Modern batching systems leverage advanced control mechanisms such as PCs, Human-Machine Interfaces (HMIs), and Programmable Logic Controllers (PLCs). These components work together to provide a user-friendly interface, precise control, and real-time monitoring.

Batching software further enhances the functionality of these control systems by offering features like recipe management, batch scheduling, and error reporting. This combination of advanced control systems and software helps achieve greater efficiency and transparency in operations.

Comparing Advanced Systems to Manual Batching Methods

When evaluating micro ingredient batching, compare these advanced systems to traditional manual methods.

Accuracy and Consistency

Advanced micro ingredient batching systems surpass manual methods in both accuracy and consistency. High-resolution precision scales ensure accurate measurement, significantly reducing errors common in manual operations. This heightened accuracy directly impacts product quality, maintaining consistency across batches—essential for industries such as animal feed manufacturing, pet food production, and food processing.

Throughput and Efficiency

Several factors impact system throughput, including feeder design, feed speeds, the number of scales, and the ability to feed multiple ingredients simultaneously.

Advanced systems optimize these factors, resulting in higher throughput rates. Scalability is another advantage; these systems can be expanded or modified to meet growing production demands, minimizing downtime and enhancing productivity. This is especially true of systems that provide a standard database program language such as Microsoft SQL, allowing for scalability of the system database as demand, ingredients, and recipes grow.

Operational Benefits

The operational benefits of advanced batching systems are substantial. Automation reduces reliance on manual labor, decreasing the likelihood of human error and increasing operational efficiency. With increasing labor shortages and competition for a skilled workforce, automation can be a welcome solution. Additionally, the safety features of automated batching systems protect operators from potential hazards associated with manual handling of ingredients.

Automated micro ingredient systems offer better operational control and aid in regulatory compliance through precise ingredient lot tracking and batch validation, ensuring that all standards are met consistently.

Upgrading Your Operations

Advanced micro ingredient systems offer unparalleled accuracy, efficiency, and operational control. These systems integrate precision weighing, multiple scales, automated feeding, and real-time data management to elevate your production process.

Next Steps

To improve your ingredient batching, start by assessing your current batching process and ensure you have an accurate list of your ingredients and example recipes to share with your batching system supply partner. This information will be critical for obtaining a concept and budget proposal for your micro ingredient batching system.

With over 50 years of expertise in custom engineering micro, minor, and major ingredient batching systems for a wide range of agricultural and industrial market segments, Sterling Systems & Controls proudly has the experience to provide you with expert guidance to achieve your automation and process improvement goals. Contact us today to discuss how our knowledge and expertise can align with your goals and how you can continue your journey toward manufacturing excellence!