Mixing/Blending Control for Compounding

A critical step in most dry bulk batching manufacturing processes is mixing or blending. Various raw materials are usually mixed/blended together in a specific proportion to produce a final compound. Mixing control is critical to quality and production efficiency. One industrial application example is rubber product manufacturing, where mixing/blending control for compounding is critical.

Most often to produce a rubber compound a combination of plastic resin (pellets, flakes, powders, or liquid) is combined with other materials, including liquids and bulk solid materials. These materials require accurate and efficient control of mixing/blending. Sterling Systems & Controls, Inc. has introduced a customized system for a rubber compounding application, including mixing/blending control. This system includes the automation of the mixing and batching processes, a bulk bag unloading system, and electrical controls.

A specialty mixer is used for rubber compounding. The workhorse mixer of rubber manufacturing is the internal mixer, or Banbury (named for its principal inventor), in which heat and pressure are applied simultaneously. The internal mixer uses two interrupted spiral rotors moving in opposite directions at a set RPM, as the compounding process requires for the specific rubber compound to be produced. The shearing action in the internal mixer is intense, and the power required for the mixing/blending operation can be quite high.

Mixer process control is required to produce the end product and is automated for optimal efficiency. This is a part of the overall automation and process control system, which includes the mixing/blending process, main batching process, auxiliary batching, drop-mill process, extruding, and cooling.

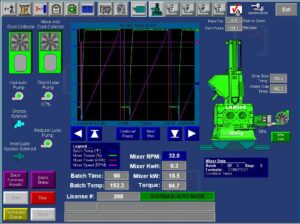

An HMI mixing screen is provided in the automation system and is an extension of the main batching screen, which shows all of the equipment associated with the mixer. From the mixing screen the user has the capability to control the mixer’s RPM on the formula being run, along with the capability to view the status of and control of related equipment. This screen also offers a data trending screen, allowing the user to view batch temperature, mixer torque/power, and speed.

Sterling Systems & Controls, Inc. has nearly 50 years of experience providing efficient solutions for the control of mixing/blending equipment, batching, micro, minor and bulk weighing, bag unloading systems, as well as plant automation. Designs utilize the latest technology to provide specialized data management, raw material management, along with production data tracking. For more information contact Sterling Systems & Controls at 1-815-625-0852 sci@sterlingcontrols.com, and at www.sterlingcontrols.com.