From Manual to Mastery: What is a Hand Prompt Batching Station?

In the world of process manufacturing, particularly in baking, pet food and treat manufacturing, and other process industries, ensuring accuracy and efficiency in batching together the ingredients required for each of your recipes is a critical challenge. You have dozens or more recipes, and perhaps from a few to a hundred or more ingredients. Many manufacturers find themselves stuck in outdated manual batching processes that are time-consuming and prone to errors. This post explores how you can go from your manual batching process to mastery of your ingredient batching by upgrading to using a Hand Prompt Batching Station. But exactly what is it?

This post explores the Hand Prompt Batching Station, and its key features and benefits, illustrating why it can be an ideal choice for improving your ingredient batching process from the manual error prone process currently used.

The Functionality of the Hand Prompt Batching Station

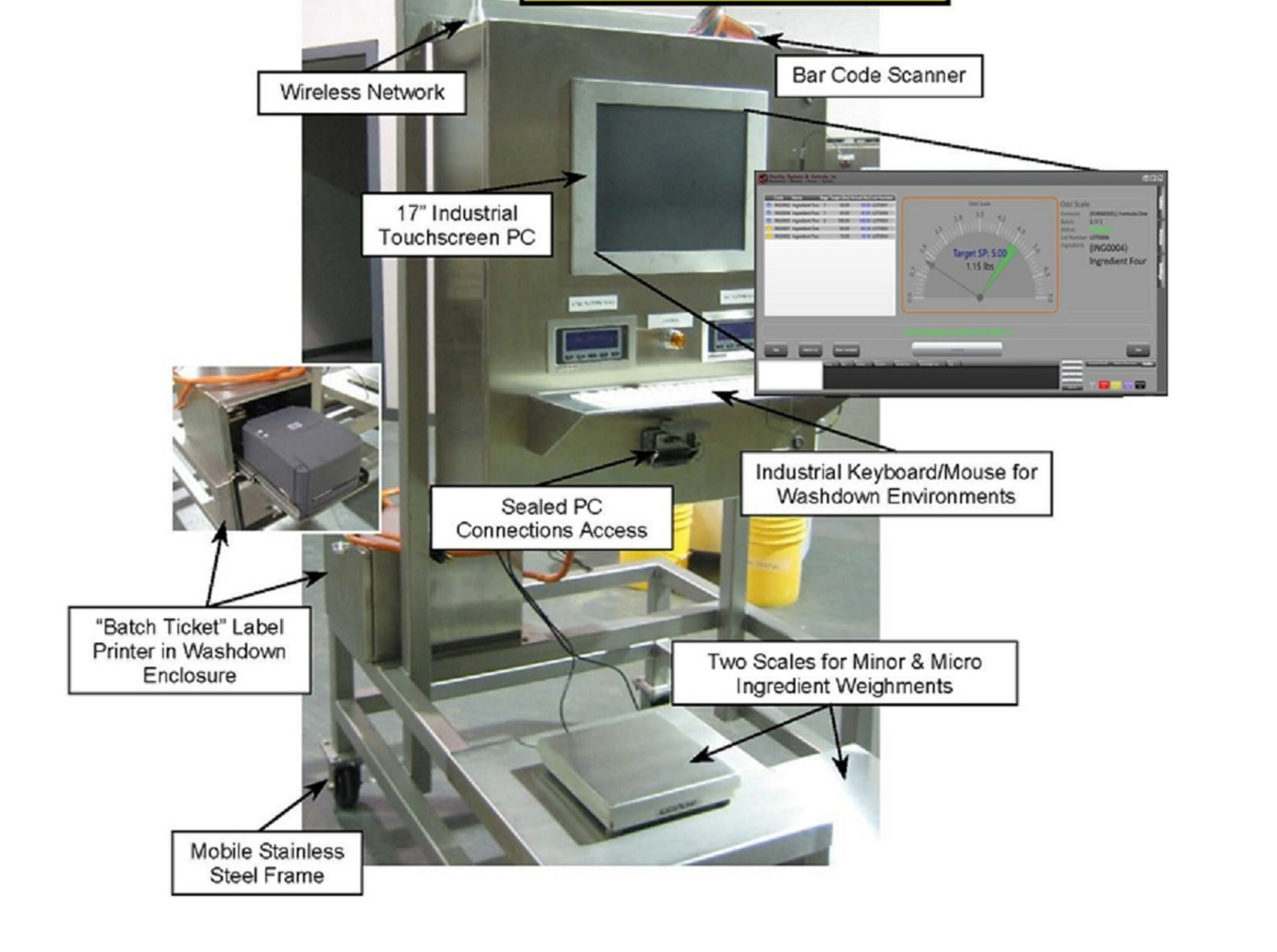

The Hand Prompt Batching Station represents a significant advancement in the world of manual ingredient batching. It is a batch control system that skillfully blends operator involvement with automated processes. This hybrid model is considered a semi-automatic system that empowers operators that manually feed ingredients into batch containers, while being guided by a series of intuitive prompts and validations that appear on the batching station’s operator-interface screen. Scale weighment of each ingredient is automatically measured by the Hand Prompt Batching Station. This approach ensures that the correct ingredient is added, and that the weighment for each ingredient is as accurate as the scale chosen to be used and integrated with the batch control system. Such careful automated oversight enhances the consistency and accuracy of the batching process allowing for important quality checks by operators.

Key Features:

Automated Operator Instructions: The Hand Prompt Batching Station is a batch control system designed to streamline the batching process with step-by-step instructions automatically displayed based on the recipe selected for processing. These automated prompts significantly reduce operator confusion and manual errors, allowing operators to focus on the task at hand rather than worrying about procedural errors.

Ingredient Validation: Every ingredient added by the operator is first meticulously verified against the specified recipe. This is a critical feature of a Hand Prompt Batching Station and guarantees that the correct ingredients are used in the proper proportions and order, minimizing or eliminating the risk of costly errors that can arise from ingredient mistakes.

Lot Tracking and Batch Validation: Maintaining a detailed history of each batch and the ingredients contained in the batch, including the ingredient lot identification and traceability, is essential for quality assurance and regulatory compliance. The Hand Prompt Batching Station is a batch control system that records all relevant data, from ingredient lots to batch processing rates by operator, providing transparency and traceability that are vital for efficiency and in industries that have regulated oversight, such as food, pet food, animal feed, etc. This comprehensive tracking system not only aids in meeting compliance standards but also facilitates easier internal and regulatory audits and recalls if ever required. Barcode and RFID tag reading options exist to assist both lot tracking and batch validation.

Standard Database Management: Data management is crucial to all process control applications and the Hand Prompt Batching Station is no exception. In fact, it exemplifies the need and use of a standard database language. Microsoft SQL or SQL Express is a standardized programming language used to manage and manipulate relational databases. A quality batch control system will use a standardized database management tool like SQL, not a proprietary system.

The Hand Prompt Batching Station enhances efficiency, weighment/batch accuracy, and product quality/consistency in the batching process. The semi-automatic batch control combines automated control system guidance with human ingredient batching expertise. In this way it ensures that manufacturers can consistently provide high-quality finished products while optimizing their manufacturing operations. This batch control system is an ideal solution for industries where precision and accountability are paramount.

Mitigating Human Error

While manual ingredient feeding has the potential for errors, the Hand Prompt Batching Station incorporates robust verification requirements. By ensuring that each ingredient is confirmed before proceeding to the next step, the system significantly reduces the risk of mistakes. This approach eliminates the common pitfalls of manual batching, such as missed ingredients or incorrect measurements, which can lead to product inconsistencies getting to market and negative impact on consumer loyalty and demand. This is especially important for small to medium size businesses that have grown significantly and struggle with their original manual methods of producing batches of ingredients to make their products.

The hand prompt batch control system also automates the tracking of where operators are in the batching process, so there’s no need to rely on printed recipes or manual checks. This level of automation greatly enhances the reliability of each batch produced, especially in an environment where the operator may be interrupted during the ingredient batching process.

Cost-Effective and Scalable

Choosing the right batching system is an investment, and the Hand Prompt Batching Station stands out as a cost-effective alternative to fully automated solutions used by larger process manufacturers for higher capacity and throughput. Fully automated systems often require significant financial commitment and complex setups, making them less accessible for smaller to medium size manufacturers.

By using a semi-automatic approach, manufacturers can streamline their processes without the heavy initial costs associated with fully automated systems. This flexibility makes the hand prompt batching station an appealing choice for businesses of varying sizes, allowing them to continue their growth and improve quality, consistency, efficiency, and even brand loyalty, all at their own pace.

Another critical feature of the Hand Prompt Batching Station that relates directly to scalability is the database language used in capturing and storing all your ingredients, recipes, and production information including lot tracking and traceability information and data. Ensure that the Hand Prompt Batching Station you choose incorporates an open and standard database language such as Microsoft’s SQL or SQL Express. SQL, or Structured Query Language, is a standardized programming language used to manage and manipulate relational databases. SQL is widely used for database management in various applications, from small-scale systems to large enterprise environments. Its ability to work with data efficiently makes it a fundamental skill for developers and data analysts. This is an important feature of a Hand Prompt Batching Station allowing it to be scalable and to grow as your business grows.

Emphasizing Precision and Consistency

Accurate ingredient measurements are non-negotiable for ingredient batching in process manufacturing. The Hand Prompt Batching Station provides the necessary precision to ensure that each batch meets exact specifications. Automatic weighing reduces the likelihood of human error, contributing to consistent product quality. A variety of scale types and sizes can be integrated with the batching station and incorporate the accuracy, capacity, and resolution that you need. You also can set the weighment tolerance you need for each ingredient.

The system’s lot tracking and batch validation features offer additional layers of safety. By maintaining a detailed record of each batch produced, manufacturers can ensure compliance with industry standards and improve product safety. This capability is particularly important in industries where quality assurance is paramount.

Integration and Real-Time Data Management

The ability to seamlessly integrate new systems into existing workflows is essential for many manufacturers. The Hand Prompt Batching Station can be connected to remote data management tools, allowing for real-time data access and analysis. This integration supports better decision-making and ongoing process optimization. Integrating the hand prompt batching station with your ERP is also possible and may provide added benefits.

Moreover, the scalability of the system, as previously discussed regarding standard databases like SQL and SQL Express, means it can grow alongside your business. Whether you operate a small bakery or a larger pet food production facility, the Hand Prompt Batching Station can adapt to your changing business needs, ensuring that you can meet increasing production demands without sacrificing quality.

Enhancing Efficiency and Quality Control

The Hand Prompt Batching Station enhances efficiency and significantly improves quality control in the batching process. Automating the batching sequence reduces the time spent on ingredient preparation, allowing manufacturers to focus more on production. Barcode and RFID scanning options exist to help lot tracking, material traceability, and batch validation to ensure the best quality and regulatory compliance.

This increased efficiency leads to higher output rates, crucial for meeting growing consumer demands. With accurate and consistent batching practices, manufacturers can assure their customers of high-quality products, fostering loyalty and satisfaction.

Conclusion

Transitioning from manual batching to a semi-automatic Hand Prompt Batching Station can truly transform your ingredient batching process. By blending operator involvement with automated guidance, you tackle the common pitfalls of manual batching—like errors and inefficiencies—head-on. This batch control system not only simplifies the process but also enhances accuracy, ensuring your products meet the highest standards, and brand loyalty is optimized for your business.

For businesses, especially smaller to medium-sized ones, the Hand Prompt Batching Station offers a cost-effective solution that scales with your growth. You can streamline operations without the hefty investment of fully automated systems, all while maintaining quality and consistency.

In the end, choosing to upgrade to a Hand Prompt Batching Station isn’t just about keeping up with the times; it’s about setting your business up for long-term success. With improved efficiency and a focus on quality, you can better meet customer demands and build loyalty. So, if you’re ready to leave the manual methods behind, this innovative batching solution might just be the key to unlocking your business’s full potential.

Next Steps

With more than 50 years of expertise in custom engineering process control solutions like the hand prompt batching station, Sterling Systems & Controls proudly has experience with batching and other process control systems. Contact us today to discuss how our process control, batching & weighing, and other process solutions can align with your goals, and how you can continue your journey towards manufacturing excellence!