Exploring Data Integration Methods: Batch Control Systems and ERP

In today’s fast-paced industrial environment, the ability to integrate data between batching control systems and Enterprise Resource Planning (ERP) systems is crucial for optimizing operations, improving accuracy, and driving overall efficiency. Effective integration facilitates real-time decision-making and streamlines processes, bridging the gap between production and business management. In this blog post, we’ll explore the three prevalent and practical methods for integrating data: Realtime WebAPI interfaces, Intermediate SQL tables, and CSV Flat Files.

Practical Alternatives

Intermediate SQL Tables/Database

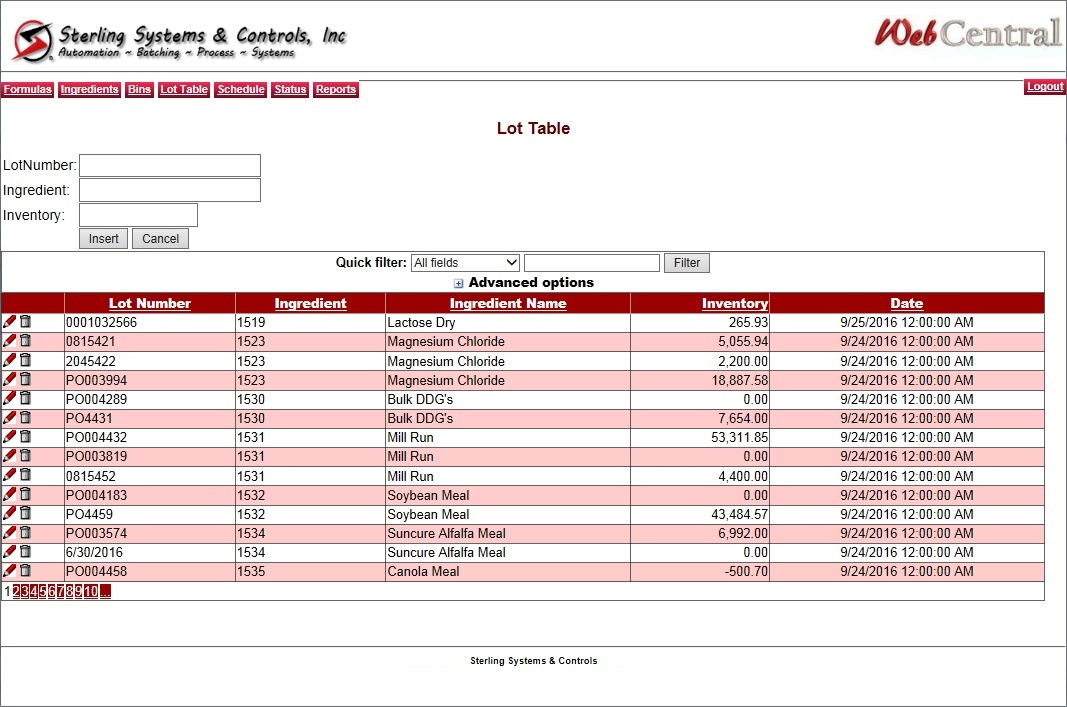

Intermediate SQL Tables bridge batching control systems and ERP systems by using a database as an intermediary layer. In this method, data from the batching control system is first written to SQL tables in a staging database. The ERP system then reads from these SQL tables to import the necessary data. Usually, multiple data tables go back and forth between the process/batching control system and the ERP. Writing data from the ERP into a buffer so the data can be massaged and validated before writing into the control table or database is common.

Advantages:

- Data Validation: Intermediate SQL tables use a buffer to provide a staging area where data can be validated and cleansed before being imported from or to the ERP system.

- Flexibility: SQL databases are highly flexible and can handle complex data structures, making it easier to map data between systems.

- Performance: This method can optimize data processing by allowing frequent batch updates rather than real-time transfers.

Disadvantages:

- Latency: Data is not transferred in “real-time,” which may result in a lag between data entry and its availability in the ERP system. The lag is usually seconds or minutes, depending on how fast the polling is set, but it isn’t truly real-time.

- Maintenance: Requires ongoing maintenance to ensure the SQL tables and integration processes remain accurate and up to date.

Realtime WebAPI Interface

Realtime WebAPI Interface is one of the advanced and dynamic methods for integrating data between batching control systems and ERP systems, but less commonly used than SQL Data Tables/Databases. WebAPIs (Application Programming Interfaces) use HTTP methods to enable direct, real-time communication between disparate systems over the web. By utilizing RESTful APIs (Representational State Transfer Application Programming Interface) or similar technologies, batching control systems can send data directly to the ERP system and vice versa. One application example is the use of a comprehensive cloud-based ERP that provides a suite of applications, including API for data integration between systems. It isn’t uncommon that middleware might be used to go between a WebAPI and SQL tables.

Advantages:

- Real-Time Data Transfer: The WebAPI interface method allows for immediate data synchronization, ensuring that both systems have the latest information.

- Scalability and Flexibility: APIs can handle various types of data and are adaptable to changing business needs and system upgrades.

- Enhanced Integration: WebAPIs can support complex data structures and facilitate more sophisticated system interactions.

Disadvantages:

- Complexity: Implementing and maintaining WebAPI integrations can be complex and may require specialized knowledge. The complexity can depend on several factors, including API documentation, system compatibility, data consistency and synchronization, performance and scalability, and more. Investigate and make sure this is really the best alternative.

- Security: Real-time data transfer demands robust security measures to protect sensitive information from unauthorized access.

CSV Flat Files

CSV Flat Files are a traditional and straightforward method for data integration. This approach exports data from the batching control system into CSV (Comma-Separated Values) files, which are then imported into the ERP system. This type of integration uses one or more text files. These files are placed into a known network folder location, and one system will write data into the file while the other system polls the folder looking for new files and then imports the data when a new file appears. These are “looser” integrations because the two systems are not required to be online at the same time and they don’t speak directly together. This type of integration relies on polling a folder every so often to look for data, so it is not “real-time.” Polling can be setup to look for new data every so many minutes, every so many hours, or just on demand. This integration works well when there isn’t a continuous network connection or when things are scheduled and submitted several hours before they go into production. Since the two systems are not talking directly together, either system can be changed easily and, if the new system still produces/understands the same import/export file format, the other system will not even know there was a new system installed.

Advantages:

- Simplicity: This method is relatively easy to implement and requires minimal technical expertise, especially compared to WebAPIs.

- Compatibility: CSV files are widely supported by various systems and tools, making it a very versatile choice for many integration process control/ERP integration scenarios.

- Cost-Effective: Typically, this approach involves lower upfront costs and less complexity in setup.

Disadvantages:

- Lack of Real-Time Integration: CSV files are unsuitable for real-time data transfer, which can impact the timeliness of data availability in the ERP system.

- Data Consistency: Managing data consistency and ensuring accurate mapping between systems can be challenging with flat files.

Conclusion

IChoosing the right data integration method between batching control systems and ERP systems depends on various factors, including the need for real-time data access, complexity, and budget constraints.

Realtime WebAPI interfaces offer cutting-edge, real-time capabilities but have higher complexity, cost, and security concerns.

Intermediate SQL tables and database integration provide a robust solution with validation and flexibility but introduce some latency depending on polling frequency. They can be “virtually real-time” and are more easily setup than WebAPI integration. They are good cost-effective solutions when as close to real-time as possible is needed.

CSV Flat Files offer simplicity and cost-effectiveness but lack real-time integration and require manual handling.

Each method has its advantages and disadvantages, and the best choice will depend on your specific operational needs and system capabilities. By understanding these methods, businesses can make informed decisions and implement integration solutions that enhance operational efficiency and accuracy.

Next Step

With more than 50 years of expertise in custom engineering process control solutions, Sterling Systems & Controls proudly has experience with integration of batching and other process system data with a variety of ERP systems. Contact us today to discuss how our process control, batching & weighing, and other process solutions can align with your goals, and how you can continue your journey towards manufacturing excellence!