Bearing Condition Monitors: Ensuring Longevity and Safety in Particle Size Reduction Equipment

In the ever-evolving world of process industries, where changes can happen suddenly and frequently, maintaining the efficiency and reliability of your process equipment is crucial. Particle size reduction machines play a vital role in diverse applications ranging from animal feed production to mining, food ingredients, and pharmaceuticals.

These machines operate based on various principles and often endure demanding conditions. Bearing monitoring systems have become indispensable to protect the longevity of this essential rotating equipment and ensure operational safety. These systems are vital components of a preventative maintenance program and play a critical role in plant safety operations.

In this blog post, we explore the importance of these monitoring systems, how they function, and why they are essential for effectively managing particle size reduction machines.

The Role of Bearing Monitoring Systems

Understanding Bearing Conditions

Bearings are crucial components in rotating machinery. They support rotating parts and minimize friction between moving elements. In devices like grinding mills and classifiers, bearings face substantial stress due to high-speed rotations and heavy loads. Over time, this stress can lead to wear and tear, which, if not addressed, may result in bearing failures. Such failures can cause extensive equipment damage, lead to costly downtime, and pose safety hazards.

What is it?

A bearing condition monitor is an advanced diagnostic tool designed to evaluate the condition of bearings continuously. These systems track various parameters such as velocity, temperature, and acceleration to determine the health and status of the bearings in the equipment. By making real-time measurements of these variables, it provides predictive insights into the health of the machine. In this way, these systems help forecast potential issues before they occur and can help drive a preventative maintenance program for the machine. This proactive approach minimizes the risk of serious failures, enhances safety, and prevents equipment damage that could require costly repairs or machine replacement.

The Importance of Bearing Condition Monitoring

Preventing Unexpected Downtime

Unscheduled equipment downtime can significantly impact both productivity and profitability. Bearing failures can contribute to unexpected shutdowns in particle size reduction equipment. Monitoring the condition of the bearings helps monitor the machine’s health and mitigate this risk by continuously monitoring key indicators such as velocity, acceleration, and bearing temperature.

Monitoring acceleration and velocity is particularly valuable for machine performance health. It assesses machine vibration and helps identify imbalances and misalignments, assesses bearing conditions, and evaluates load conditions. By detecting changes in acceleration, the system can identify deviations from average baseline operating performance, allowing personnel to schedule machine maintenance and address issues before they result in costly breakdowns.

In addition to early detection of bearing problems, these systems may also help identify the root causes of issues, such as misalignment or imbalance due to other part wear. This supports more informed maintenance decisions and interventions. By integrating an output from the condition monitoring system to the process control PLC, which could be monitoring and controlling multiple pieces and types of equipment, with other maintenance management planning systems, these systems also facilitate the scheduling of maintenance during planned downtime, minimizing the potential for unexpected interruptions. This proactive approach is critical to the implementation of a preventative maintenance strategy.

Enhancing Equipment Lifespan

Regular monitoring of high-speed particle size reduction equipment using a bearing monitoring system significantly extends the equipment lifespan by enabling the early detection and alerting of potential failures. As discussed previously, maintenance teams are notified of issues by continuously monitoring the critical parameters associated with the mill condition before they escalate into major problems. This proactive approach allows scheduling maintenance based on a warning rather than reacting to sudden breakdowns resulting in costly unplanned downtime. Consequently, integrating the predictive capabilities of these systems with a preventative maintenance program creates a comprehensive and holistic maintenance strategy. This integration will enhance the lifespan of your particle size reduction machinery.

Ensuring Safety

Safety is a paramount concern in any industrial setting. Bearing wear and failures in size reduction mills have the potential to cause severe equipment malfunctions, presenting significant risks to personnel and the surrounding environment. By employing a system to monitor the condition of the mill bearings holistically, potential safety hazards can be detected, and a controlled equipment shutdown process can be started to mitigate accidents. This proactive approach helps prevent equipment-related incidents, contributes to a safer work environment, and supports compliance with safety regulations.

How Bearing Condition Monitoring Systems Work

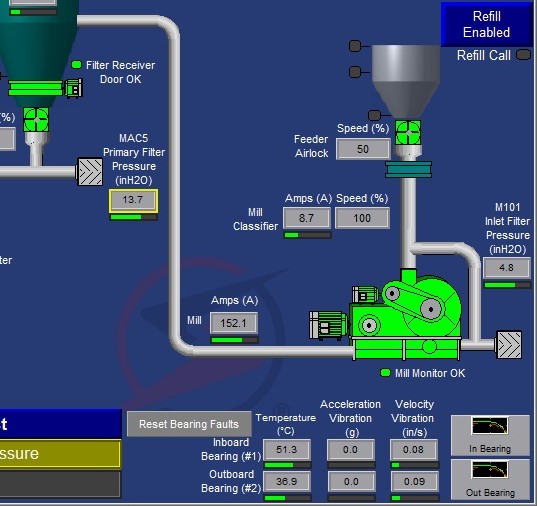

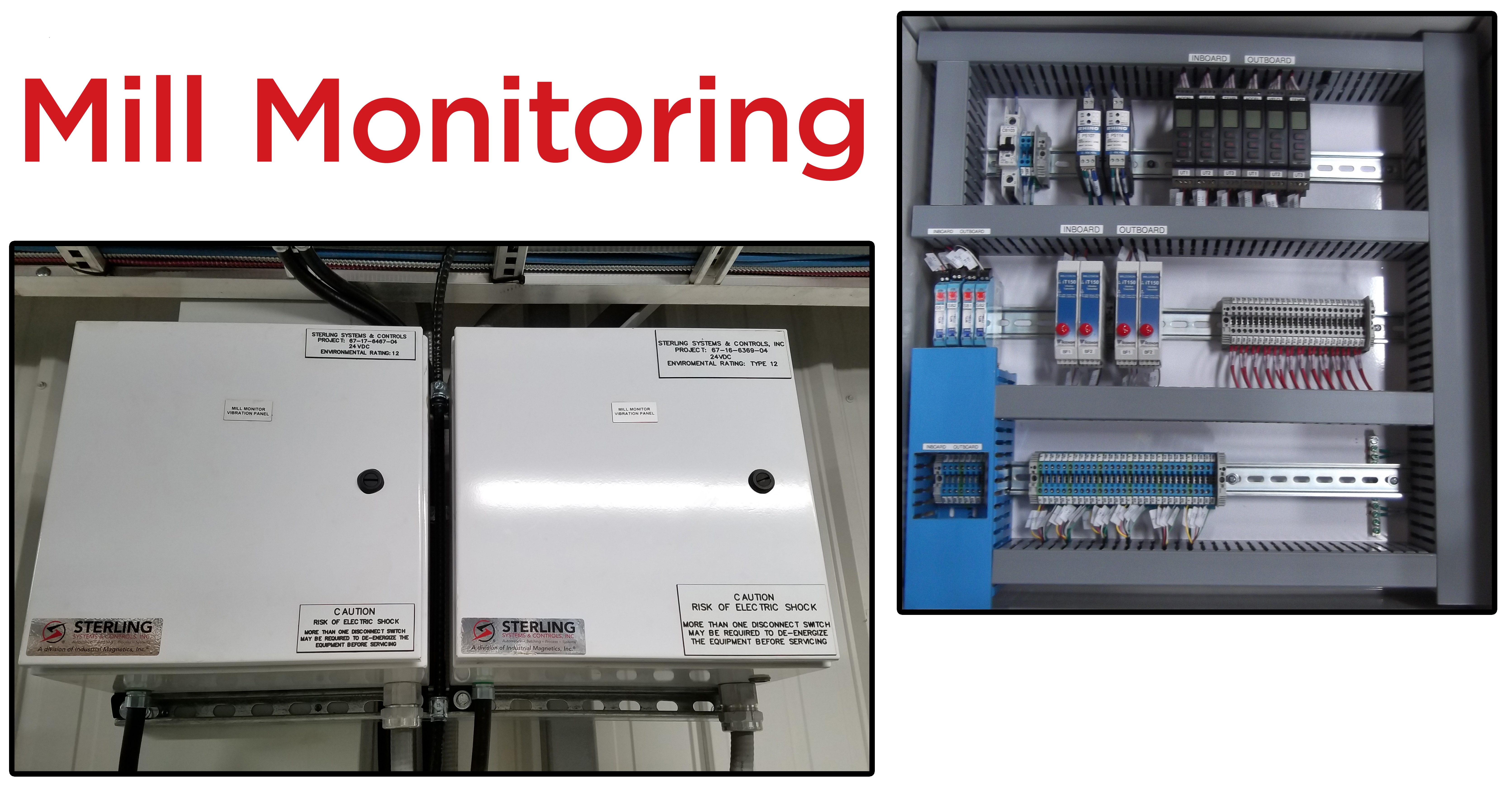

Key parameters measured include bearing temperatures, acceleration, and vibration for both inboard and outboard bearings. The sensors for each function are wired to modules using multi-conductor cabling. Typical bearing monitoring functions use an acceleration module for both temperature and acceleration. An acceleration module is used for both inboard and outboard bearings. A separate module and cabling connect sensors to a velocity module, one for inboard and one for outboard bearings.

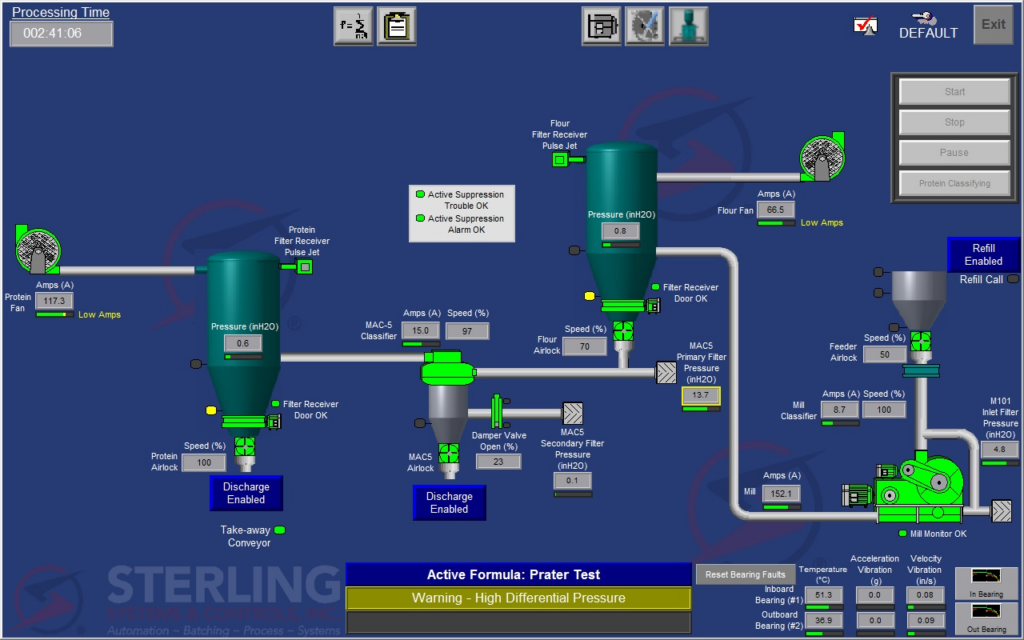

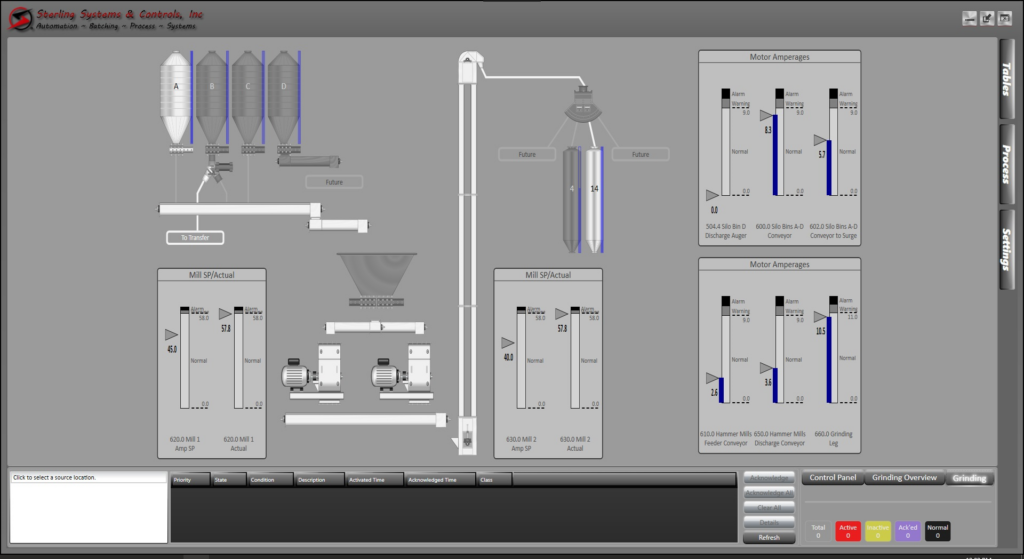

Monitoring temperature, acceleration, and velocity for each bearing set can be incorporated into standalone or integrated systems. An integrated bearing monitoring system is when an overall control system for the grinding and classifying function exists, and the mill bearing monitoring is integrated into the control system. Standalone systems are separate control panels strictly for the bearing monitoring function.

- Velocity Monitoring: A velocity-sensing module is used to detect the speed at which vibrations move. This can indicate the intensity of the vibrations in the mill at the inboard or outboard bearing module. By identifying abnormal velocities, these systems can signal possible problems such as misalignment, imbalance, or bearing damage.

- Temperature Monitoring: Elevated temperatures can indicate bearing problems, such as excessive friction or lubrication failure. These systems are equipped with temperature sensing capability to measure bearing temperature and alert maintenance teams to potential overheating conditions.

- Acceleration: The accelerometers monitor acceleration, which is the velocity change rate. They can detect rapid changes in vibration levels, are sensitive to sudden changes, and are better at detecting these sudden problems. They can also monitor the intensity of the mill vibration over time.

Monitoring of Critical Parameters

Monitoring systems continuously monitor the various sensor modules. This is then compared to baseline data for the particle size reduction mill to assess the condition of the bearings. Baseline data is fundamental and must be obtained from the particle size reduction mill manufacturer and incorporated into the monitoring system by its manufacturer. Typically, these systems provide alarm/event notification of a warning or failure condition.

Integration with Maintenance and Process Control Systems

Many bearing condition monitoring systems can be used with existing maintenance management systems. This integration allows maintenance teams to schedule interventions and manage maintenance activities more effectively. Real-time alerts ensure that decision-makers have access to up-to-date information for timely action.

The control of the grinding or milling process incorporates the mill health monitoring discussed in this blog post. In addition, the grinding or milling control system will monitor and use motor amperage and setpoint establishment to monitor overall machine health and performance.

Benefits of Implementing Bearing Condition Monitoring

Cost Savings

A bearing monitoring system can yield significant cost savings by preventing unexpected equipment failures. These systems continuously monitor critical parameters such as velocity, acceleration, and bearing temperature. By comparing these parameters to baseline information, potential issues can be detected before they escalate into serious problems. This proactive approach helps avoid costly emergency repairs and replacements and allows for more effective maintenance scheduling, thereby managing maintenance budgets more efficiently.

Increased Operational Efficiency

Effective bearing condition monitoring enhances operational efficiency by reducing unplanned downtime and preventing breakdowns. Monitoring velocity and acceleration helps understand vibration levels while bearing temperature measurements provide insights into the thermal condition of the bearings. This comprehensive approach ensures consistent equipment performance, which is crucial in industries like feed manufacturing, food processing, pet food production, and pharmaceuticals, where precision and reliability are essential. Improved efficiency results in stable production processes and higher product quality, ultimately leading to greater productivity, operational stability, product quality, and safety.

Data-Driven Decision Making

Although the system does not store extensive historical data, it provides valuable real-time insights by monitoring and comparing parameters against baseline information. Immediate alerts are generated when velocity, acceleration, or bearing temperature deviates from normal ranges, allowing maintenance teams to address issues promptly before they develop into critical problems. This real-time feedback supports a proactive preventative maintenance strategy, enabling quick responses to emerging problems and contributing to improved equipment performance and reliability.

Best Practices for Implementing Bearing Monitoring Systems

Selecting the Right System

Choosing the right bearing monitoring system is crucial for achieving effective results. The selection process should be based on the specific needs of your equipment and the operating environment. Key factors to consider include the type of equipment, operating conditions (including electrical location requirements such as hazardous areas), and the range of parameters to be monitored (e.g., velocity, acceleration, and bearing temperature). It is advisable to consult with industry experts and conduct a thorough assessment to ensure that the chosen system meets all operational requirements and provides accurate and relevant data.

Calibration and Maintenance

Modern sensor technology for monitoring the particle size reduction mill bearings’ acceleration, velocity, and temperature should never require calibration. Setting up and understanding each baseline is vital, and communication between the mill manufacturer and the bearing monitoring system manufacturer is essential. If the mill being monitored ever changes in mill style, brand, or size, then the baseline parameters for the new or revised mill needs to be examined, and possible adjustments made to the monitoring system setup. Consult with your chosen monitoring and control system manufacturer.

Training and Education

Proper training for maintenance and operations teams is fundamental to leveraging the full potential of these systems and your size-reduction equipment. Comprehensive training programs should include instruction on understanding the system function and principle of operation, best practices in responding to alerts, and integrating insights from the monitoring system into your maintenance workflows. This will help educate personnel on how to use the system effectively. Well-trained staff can maximize the benefits of the system, enhance maintenance strategies, and contribute to overall operational efficiency.

Conclusion

Monitoring equipment conditions is essential for maintaining the reliability and efficiency of particle size reduction machinery in process industries. By providing real-time insights into parameters such as velocity, acceleration, and bearing temperature, these tools help prevent unexpected downtime, extend equipment lifespan. Their capability to offer immediate feedback allows for early detection of potential issues, enhancing operational safety and efficiency.

Implementing effective condition monitoring enables a proactive approach to maintenance, optimizing operational performance and contributing to a more cost-effective maintenance strategy. Integrating real-time monitoring into maintenance practices is an important tactical move toward achieving operational excellence for maintenance managers, operations managers, facility managers, and process engineers. This approach ensures the long-term success of industrial operations by improving safety, productivity, and overall equipment performance.

Next Step

With over 50 years of expertise in custom engineering process control and automation systems, material weighing, ingredient batching, liquid handling, and other bulk material handling solutions for a wide range of process industries, Sterling Systems & Controls proudly has the experience to assist you in achieving your automation and process improvement goals. Contact us today to discuss how our knowledge and expertise can align with your goals and how you can continue your journey toward manufacturing excellence!