Automation Upgrade

It isn’t unusual for Sterling Systems & Controls, Inc. equipment and controls to be upgraded and enhanced over years of operation. Mechanical equipment gets replaced or added, the process changes and/or expands, and PC and operating system technology continues to evolve, usually for the better making things more cost-effective and efficient. Automation is no exception. An automation upgrade is often performed after several years or when an event may necessitate it. In addition, it is not unusual for companies to begin with a small modular system, like batching with four (4) ingredients, and then expand over time by adding more ingredients and formulas.

Sterling Systems & Controls is experienced and very accomplished at assisting customers through the evolution of their process, equipment and systems. The evolution of automation especially is something that tends to get upgraded over time. Automation technology changes fairly quickly so that the state-of-the-art today is not the state-of-the-art in another year or two. Those companies involved with designing and creating automation systems and capabilities are constantly keeping in touch with changes in hardware and software standards and tools. Let’s take a look at an example of an automation upgrade.

Cattle Feed Yard

Over a decade ago, Sterling Systems & Controls was approached and asked to replace an existing batching system (by other manufacturers) with a large cattle feeder operation. The reason Sterling Systems & Controls was brought in was because of the absence of support from the previous system supplier, as well as some performance issues. The application was a cattle feed operation that blended and mixed liquids and solids to feed a mixer and produce the final feed end product. Sterling Systems & Controls proposed a customized seven (7) scale Batching Control Software System with the interface to the existing control panels, PLC hardware, and the PLC network for the customer feed yard weighing and mixing equipment. No wiring changes were anticipated, and the proposed new software system was based on what Sterling Systems & Controls had done at a different customer location for a similar application; the basics of the system design had been proven.

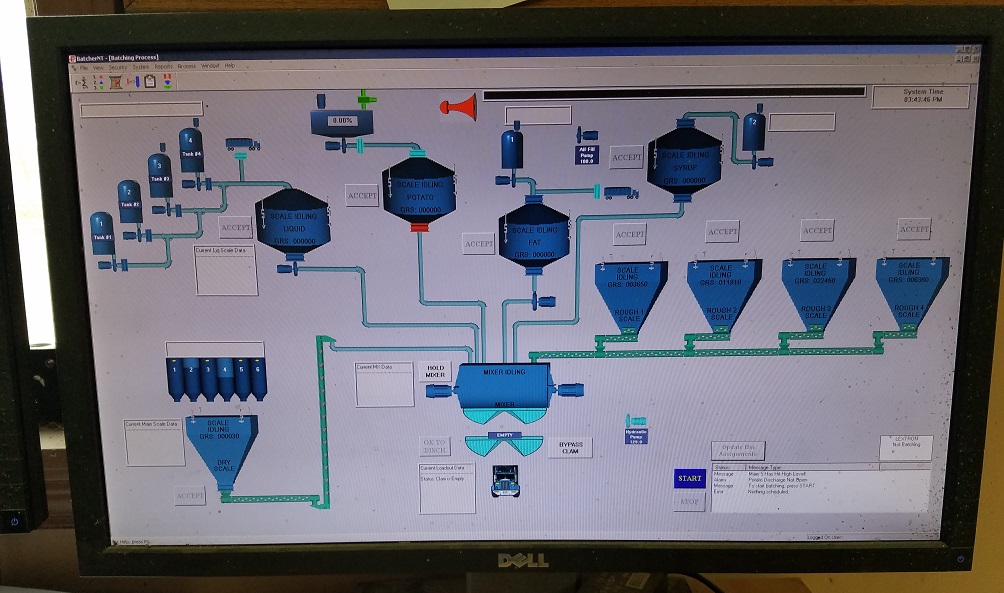

The replacement batching system software that Sterling Systems & Controls supplied utilized a Desktop PC (supplied by the customer) running Sterling Systems & Control’s new (at the time) Windows-based Batching Software. The PC was connected to the existing customer Control Panel(s) that house the Programmable Logic Controller (PLC), and the PLC provided Input/Output (I/O) interface to the field devices.

The existing manual Control Panel enclosed the seven (7) weight indicators and panel-mounted switches for manual backup capability. The batching system incorporated standard batching features such as the multi-tasking capability that allows the system to batch while editing or checking formulas, formula creation, ingredient lot tracking and batch validation, ingredient inventory/usage, and other main menu functions. According to the customer, one major benefit of the Sterling Systems & Controls batching system is that it produces batches faster than the previous batching system supplied by others.

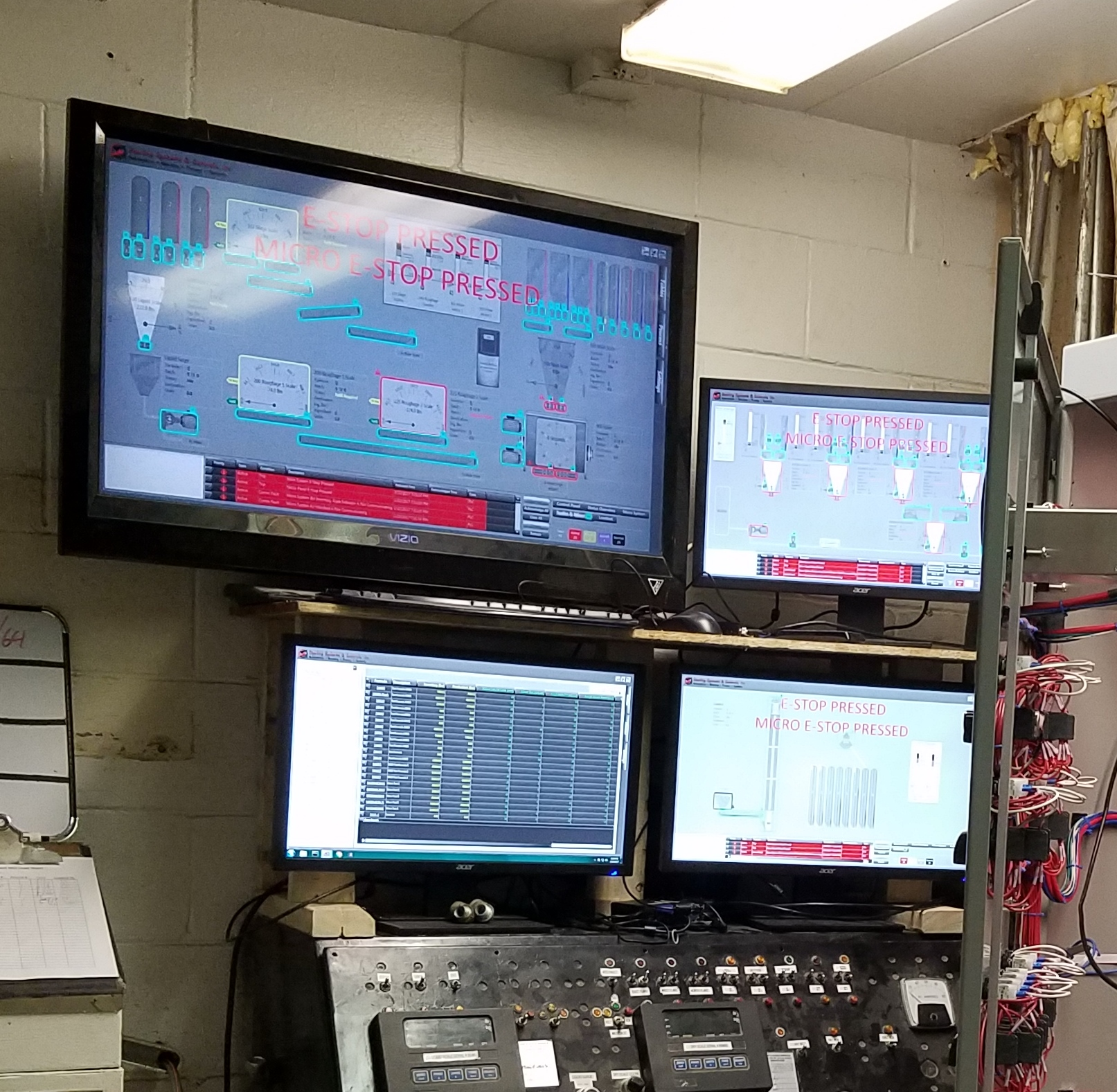

Over the years, there have been several additions or modifications to the Sterling Systems & Controls batching system performed by Sterling Systems, working with the customer. The automation upgrades in these changes include additional report functions, a remote display monitor, additional scale modifications, a lot summary table, and most recently, a major upgrade and modification in automation software and graphic interface. The system’s modular nature and continuous upgrade in state-of-the-art capabilities by Sterling Systems & Controls allows for the premier support and growth of the batching system by Sterling Systems & Controls on behalf of the customer. In the most recent upgrade, Sterling Systems & Controls supplied the following automation equipment to upgrade the existing Sterling Systems & Controls batching system:

- Computer Equipment Rack containing one (1) new Main Batching Computer, one (1) new Server Computer and Console, two (2) network switches, and one (1) battery backup unit.

- New Allen-Bradley PLC with required I/O modules.

- Replacement doors for existing enclosures that will have a new Allen-Bradley PanelView Plus touchscreen and ten (10) new scale indicators mounted. This is to upgrade the existing manual panel that was installed by others. This also increased the scales from seven (7) to ten (10) as more dry materials were added to the batching formulas.

- New Ethernet I/O Panel for new Grinding Equipment.

- New Grinding/LIW Panel with Allen Bradley PanelView Plus touchscreen for control of new Grinding Equipment.

With the new PC came the upgrade from Sterling Systems & Controls’ legacy batching system software to the current state-of-the-art software using Microsoft .NET. .NET is a framework that runs on the latest Microsoft OS and provides programming guidelines for a wide range of applications in this case, the Sterling Systems & Controls batching system software.

The automation upgrade for the new system also included a host of upgrades, including grinder monitoring and a supervisory remote control application called WebCentral™ Supervisory Control. WebCentral™ is a software package that allows corporate users to access the database of a Sterling Systems & Controls, Inc. batching control system. This can be used to manually enter and manage all configurable items using a PC’s web browser.