Kitchen Batching System

A semi-automatic ingredient batching system for the food industry is often referred to as a Kitchen Batching System and is similar to the Sterling Systems & Controls, Inc. Hand Prompt Batching Station. This multiple bin Kitchen Batching System requires operator involvement for the batching operation but it is also automated in the control of the operator actions and ensures accurate weightments and batch consistency. Operator interruptions will no longer be a problem, and that means no more missed ingredients. The Kitchen Batching System improves speed and overall efficiency of the ingredient batching process over a manual process.

Included in a typical customized Kitchen Batching System are:

- Multiple ingredient bins/totes

- Stainless Steel Table(s)

- Moving weigh table w/ scale and touchscreen display

- PC Control Panel with weight instruments

Ingredient Bins

Each Kitchen Batching System is customized to include the maximum number of bins required by the customer’s specific formulas. The bin size can vary depending on the weighment sizes required per ingredient for each batch, and how much in-bin inventory is desired to be kept. Two-size bins are often utilized. The larger bin has a capacity of 2.75 cubic-feet to 4.1 cubic-feet and includes rugged casters for ease of movement in/out from underneath the Kitchen Batching System tables. The small bin has a nominal capacity of approximately 0.84 cubic-feet of bulk solid material and sits on the tabletop. The bins are manufactured of food-grade material and have clear lids and integrated material scoops.

Tables

The Kitchen Batching System tables are sized to fit with the number of ingredient bins and for operator comfort. The size of the tables depends upon the number of bins required in the system. The tables are manufactured of stainless steel material, typically grade 304. The ingredient tables are of rugged construction and are designed to be stationary. The scale platform is also constructed of 304 stainless steel. However, the scale platform table is designed to travel smoothly between the two ingredient tables. The operator simply moves the scale platform table to reach the required ingredient bin. A roller system attaches the platform scale table to the ingredient tables. The scale and the operator interface touchscreen are mounted to the top of the scale platform table. The cabling from the scale and touchscreen display is mounted within a flexible cable carrier and is routed between the scale platform table and an adjacent ingredient table.

Control Panel w/ Touchscreen Display

We know electrical controls and automation technology and can customize a system for our customers using standard control and automation components. We use a PC (control panel mounted) for the Kitchen System and an industrial touchscreen monitor (scale platform table mounted). The control panel encloses the PC and other components to allow for its operation and interface with the monitor and scale. A weight indicator is also included and mounted on the front door of the enclosure. A barcode and/or RFID scanner can also be provided for operation with the lot tracking and batch validation part of the control system.

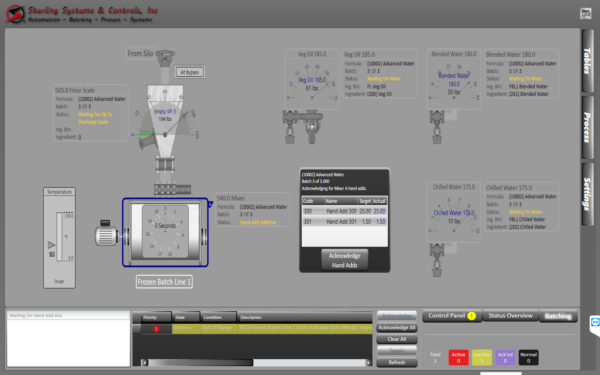

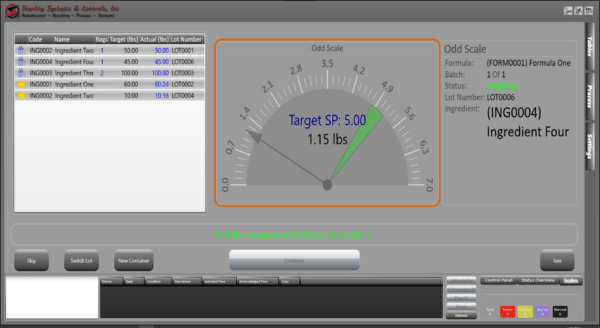

The Kitchen System is a semi-automatic control system using a hand prompt batching process. The main concept of the hand prompt batching process is to guide an operator through the steps necessary to weigh-up the required ingredients for a given formula/recipe. Once the system is started, it will begin at the first line in the formula and ask the operator to locate and weigh the specified ingredient. The system will automatically take tare weights as appropriate while it runs, and enforce a set of programmable tolerances be maintained for each ingredient.

The system will watch the net weight on the scale and will not allow the operator to continue on to the next ingredient until the current net weight is within the acceptable tolerance band and the operator has pressed the continue button to acknowledge the addition of the ingredient. The Kitchen Batching System controller captures the actual weight information and records it into a database along with the ingredient lot information (if enabled), making it easy to track, enforce, and confirm that the correct ingredients are getting into each and every batch.

From an operator’s perspective, the system is very easy to operate; all they need to do is press the start button, read the screen, and follow the instructions. All manual calculations are eliminated as the system automatically calculates and computes target weights, bag counts, and tare weights.

The Kitchen Batching System controller can track raw ingredient lot numbers and store this information with historical batch data. Lot Tracking can be easily enabled by setting the “General – Ingredient Lot Tracking” system parameter to either “Validate” or “Prompt”. When set to “Prompt” the system will stop and ask the operator to scan or enter a lot number before weighing each ingredient, but the lot number will not be validated. It will simply be stored in the database with the historical information. When this parameter is set to “Validate” the system will prompt the operator to either scan the barcode of a valid lot or pick a valid lot from a list. Lots must be entered on the Ingredient Lot Table screen and the system will validate the lot number to be sure it is the correct ingredient from the correct lot. After the operator provides a valid lot number, the system will prompt the operator to weigh the required ingredient. The system will not allow the operator to continue until a valid lot has been entered or scanned.

An alternative to the standard side-by-side table Kitchen Batching System is the Inline Kitchen Batching System. This provides for a different “footprint” and orientation. While being less common than the side-by-side table system, it is a nice alternative.